Introduction

Woodworking has long been a popular craft and hobby throughout human history. Our ancestors made tools, furniture and other items with wood, often taken from nearby forests or other wild environments. While the methods have changed over time, with modern technology taking over some of the traditional techniques, woodworking remains an important skill for both recreational and professional woodworkers around the world.

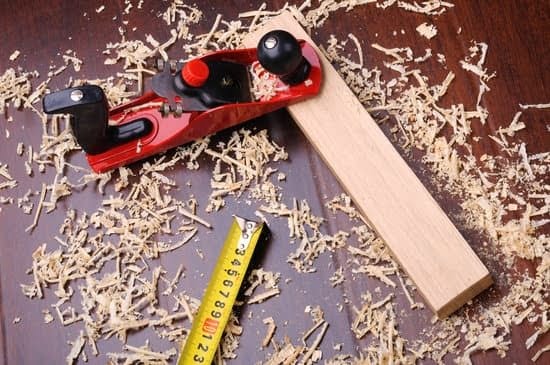

The traditional tools of woodworking evolved over hundreds of years to accomplish everyday tasks such as chopping firewood, building furniture and making tools. The early pioneers used simple hand-powered saws, planes, chisels and augers while more complex machines such as table saws, band saws and mortisers were developed in the late 19th century. Handheld power tools such as routers and drills also became available for more precise tasks.

Modern advancements in manufacturing have also allowed for greater replication of materials which has revolutionized the industry as well. Plywood, medium density fiberboard (MDF) and other composite materials are providing alternative options for furniture pieces that are more affordable, lighter weight and easier to assemble than traditional pieces from solid hardwoods. New manufacturing techniques can reproduce intricate patterns like parquetry, chevron designs and inlays which make high-end cabinetry accessible to everyone at an affordable price point.

With all these advancements in tool developments and materials it is now easier than ever to build a home woodworking shop. A well-stocked shop will not only create beautiful wooden items but will also give you great satisfaction with each job completed. Setting up a shop may require construction space or dedicated storage shed but it can be done on any budget or scale depending upon your own goals and needs in your projects.

Identifying Necessary Space and Tools

When building a woodworking shop, it is important to evaluate the necessary space and tools needed. This includes not only items that are essential for completing various woodworking projects, but also items and accessories that may enhance the experience of working in the shop. Examples of tools to consider include saws, routers, drill presses, planers, clamps, sharpening stations, sanders and more. In terms of space considerations, a good rule of thumb is to have 10-20 sq feet for each type of tool. Workbenches should be examined to ensure they can either be repurposed or replaced with models designed for woodworking shops that have integral tool storage capabilities. Other accessories that should be considered include dust collection systems (to help clean up sawdust and other debris) as well as lighting fixtures such as overhead task lamps or track lights to provide additional visibility while working on projects. Finally, when designing shop plans consider the placement of these elements to ensure efficient movement and workflow throughout your shop.

Building the Structure

When building a woodworking shop, it is important to take into account any local codes and restrictions that may apply to your project. This includes considering the permit requirements in your region, such as building permits or zoning permits. It is also beneficial to do research on building codes–for example, which materials are approved in certain areas and what type of footing is necessary for certain structures. Furthermore, understanding safety standards related to the type of building you are constructing can help the project proceed smoothly and ensure safety measures are taken into account. Additionally, make sure to consult an engineer or other qualified source if you plan on making any structure modifications during construction. Finally, when beginning the actual construction process, ensure adequate foundation strength and use resistant material based on the weather conditions in your area. With proper research into local laws and regulations as well as careful execution of your plans, constructing a woodworking shop can be an enjoyable and rewarding experience.

Selecting Quality Tools

When it comes to building a woodworking shop, selecting quality tools is essential. It is important to research recommended brands and products, such as DeWalt, Craftsman, and Bosch drills, saws and sanders. All three have an established reputation for durability. Additionally, it may be beneficial to explore newer tools with innovative features such as cordless technology or variable speed features which can help facilitate the woodworking process. Investing in a quality set of tools right away can save you the trouble of having to replace them down the line due to premature wear or damage caused by inferior materials. Not only that, but using high-quality tools will allow you to build projects faster with more accuracy and precision resulting in better finished products.

Outfitting and Organizing the Shop

When outfitting and organizing a woodworking shop, it’s important to consider both the furnishings and the shop layout and ergonomics. Think about where you will place different tools and machines in what can often be an small or limited space. Planning ahead will make setting up a shop much more efficient. Storage is also important so that tools are easy to access, while not impacting the flow of your workspace. Consider smart shelving placement, pegboards, tool chests, wall-mounted bins, and other items that enable efficient storage. Safety should also be considered when outfitting a woodworking shop. Ensure there is adequate lighting throughout your workshop as well as appropriate ventilation systems. You may need to install dust collectors or exhaust fans depending on the type of projects you plan to tackle. In addition to organizing the workspace, ensure adequate flooring exists for approaching materials safely and comfortably – consider anti-fatigue mats to alleviate standing stresses from long hours on your feet. Lastly, don’t forget chairs for aid in comfort if needed during breaks!

Safety and Comfort

When any type of woodworking shop is established, it’s imperative to focus on both safety and comfort. Providing employees with personal protective equipment (PPE) is essential. This includes safety goggles, gloves, ear protection, dust masks and more. Properly training employees in the use of tools and machines should also be part of the process. This helps to ensure that they are handling these items safely and correctly. Incorporating effective methods for reducing the risks associated with woodworking is also important. Things like adding additional extractor fans, changing the layout of workshop furniture and tidying up spilled materials can go a long way towards creating a safer working environment. In addition, ensuring the temperature remains at a comfortable level for those working in the space can help avoid accidents or discomfort due to excessive heat or cold temperatures. Creating a safe and comfortable work environment should always be one of the top priorities when setting up any woodworking shop.

Create a Custom Tabletop

Creating a custom tabletop is a great way to customize your woodworking shop. Depending on your style and needs, the type of wood can range from pine and maple to cherry and mahogany. Each wood has its own look, so you will want to make sure that you choose the one that fits your expectations the best. Another option for customization would be the finishing of the tabletop. By staining it or painting it, you can give the piece an entirely different look that matches with other pieces of furniture in the shop. You could even add a few decorative details such as carvings or decorative trim for a more elaborate look. With some creativity, you can create something unique for your woodworking shop that suits your individual tastes and needs.

Finalize the Shop and Enjoy

Once the basics of the woodworking shop have been established, there are numerous ways to further customize it. Automation can increase efficiency and reduce fatigue, especially when performing labor-intensive tasks like cutting or jointing. Connecting the shop to the internet can open up many new opportunities, such as communication with other woodworkers and access to exclusive resources to help develop skills in this craft. Providing a space for research and practice is also essential when it comes to mastering new techniques in woodworking. This could include items like bookshelves to store reference materials and a designated workbench that encourages productivity. And finally, investing in a selection of tools appropriate for the projects intended will really streamline your workflow while giving you more flexibility and control over your results. With these steps finalized, your woodworking shop is sure to be an enjoyable enjoyable space that allows for more creativity and independence, ultimately bringing greater satisfaction from each project completed.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.