Introduction

Edge beading woodworking is a type of woodworking that focuses on creating curves and ornamental trim pieces. It utilizes special tools such as router bits and chisels to craft beautiful edges, curves, and trim on wood surfaces. Edge beading is used in several decorative applications including furniture, cabinetry, doors, floors, and more. It is also commonly used in staircases and wainscoting. The process involves cutting a piece of hardwood or plywood from an inside corner to form the desired shape or pattern (beading). Beads can range from quite simple to complex depending on the desired design. Edge beading can bring life to a piece adding an element of sophistication by giving it a refined look due to the smooth curved lines. This technique requires precision and skill as each project may require different types of routing patterns and depths. In addition, using the proper diameter for each routing bit helps ensure accuracy when working with curved shapes. Certain types of woods might require additional sanding or staining for better finishing touches. All in all edge beading woodworking is an excellent way to achieve unique and creative results when it comes to decorative woodworking projects.

Step-By-Step Guide to Edge Beading Woodworking

1. Start by cutting and milling the wood to your specifications, making sure that all pieces are measured with accuracy and precision.

2. Sand the edges of your wood until smooth, providing for a better finish in the end.

3. Select the type of edge beading you wish to use for your project and measure out the correct amount for each side of the wooden piece; mark out where you plan on placing it, using a pen or pencil.

4. Use a router to cut into the wood along your designated lines in order to form channels for edge beading (the depth of your cuts will depend on the size of edge beading you are using).

5. Place glue into the routed cuts and press edge beading down into them firmly with a mallet or hammer, allowing it to securely attach to the wood surface.

6. Once dried, gently sand down any rough edges or excess material that may exist around edges beads before sanding entire project as desired for refinishing later on down the line.

Materials and Tools Needed for Edge Beading

Edge beading is a popular woodworking technique used to create a decorative edge on wooden pieces. Learning to do edge beading is an essential skill for many woodworkers because it adds a distinctive and attractive design element to furniture, as well as providing added strength and durability. To complete this type of work, certain materials and tools are required.

The most important materials in edge beading are the wood itself, some kind of adhesive and either pre-made or custom-made corner moulding for the design element. Depending on the project, additional Wooden products like veneer may also be needed; such as: wooden plugs, dowels screws and nails. A wood router with various bits is also necessary for routing out channel that will fit the corner moulding; other tools might include: saws (both hand and power), chisels and miter boxes. Additionally specialty tools can be used such as router jigs, specialized sanding blocks or files for shaping edges as well some type of measuring tool to make sure everything fits together properly (either steel ruler, or vernier calipers).

Benefits of Edge Beading Woodworking

Edge beading woodworking is a technique that provides additional structural support to otherwise weak and vulnerable wooden edges. There are several advantages offered by this process, namely:

1. Enhanced Strength and Durability: The beading strengthens the edges of your furniture or other wood products, making them less prone to warping or splitting over time. This can help prolong the life of your creation and make it more resilient against everyday wear-and-tear.

2. Improved Aesthetics: Edge beading adds an attractive accent along the edges of a piece of furniture or any craftwork made from wood. It increases visual interest and, when combined with stains, oils, and waxes, can really bring out the beauty in any finished product.

3. Protection from Moisture Damage: As a decorative element, edge beading can also provide moisture protection for exposed surfaces around doors and windows during heavy rains or snowfalls. It creates a barrier to help keep moisture away from square edges where water could potentially seep in and cause damage over time.

4. Reduced Necessary Repair Work: When properly applied, edge beading prevents most common issues associated with weathering such as cracking seams, lifting boards and warping panels on cabinetry, which ends up saving time and money for repair work in the long run if you’re working on furniture projects or trying to replicate an antique design on timber construction devices.

Creative Edge Beading Ideas

Edge beading woodworking is a smooth and decorative edge finish that can be applied to any woodworking project. This type of woodworking utilizes small, thin pieces of material, usually metal or plastic, which are installed on the edge of the piece to create a unique look. Edge beading can be used to hide unsightly blemishes or create texture, adding aesthetic value to the piece. It can also help protect the edges from damage over time by giving them more stability and reinforcement.

Edge beading has been around for centuries and has become increasingly popular with modern-day woodworkers who want to add unique character and style to their work. Creative ideas include using different materials such as gold, silver, brass, copper and more; using geometric shapes; adding trimming along the edges; playing with designs such as weaves and swirls; mixing vibrant colors; layering multiple trims of various textures in different directions; incorporating materials like glass beads, wool fibers or marbles; creating mosaics along edges; or even replicating natural elements for a polished look. With some creativity and imagination, people have been able to come up with very artistic edge beading designs that truly bring out the beauty of their wood working projects.

Tips and Tricks for Edge Beading Woodworking

Edge beading is a type of woodworking decoration that gives your furniture a professional and polished look. To achieve this look, you’ll need to use a router with an edge beading bit, as well as the appropriate dies and templates for the desired patterns. Before you begin your edge beading project, there are certain tips and tricks to keep in mind:

• Choose the right template for the project: As mentioned previously, the types of templates you use will depend on what kind of pattern or effect you are attempting to create. Typically, larger projects require more intricate designs or intricate tools to achieve sharp edges and rounded corners. Make sure you choose templates that match your skill level accordingly.

• Carefully measure your cuts: Before you begin to route each section of your edge beading project, it is important to accurately measure out each cut beforehand. This allows you to make any necessary adjustments before starting on a section instead of after once it’s already been routed.

• Take it slow: If possible, start at the slower end of router speed when first starting out with edge beading projects; while experienced woodworkers may choose higher speeds, slower speeds provide better control which can prevent mistakes and create cleaner jobs overall.

• Gather all materials in one place: Have all needed materials on hand before starting an edge beading project such as routers, router bits, jigs/fixtures, clamps, safety equipment etc., so that everything is readily available when needed.

Common Mistakes to Avoid in Edge Beading Woodworking

Edge beading woodworking can produce delicate, intricate pieces of art. However, even the most experienced woodworkers can make mistakes. To ensure you don’t run into problems while edge beading, there are a few common mistakes to avoid:

1. Not Preparing the Wood: It is important to condition and prepare the surface before beginning any work with edge beading tools. This involves sanding and possibly priming or staining the surface of the wood prior to using any tools. If you do not take this important step, your final product will not look as smooth or professional as it should.

2. Incorrectly Positioning The Bead: Once you have chosen an appropriate profile for the design you are creating and set up your tools, the next step is to rout or cut out the bead shape along the edge of the wood piece. Be sure to leave enough room between each side of your bead so that it fits nicely when placed on top of the piece of wood being worked on; if it isn’t positioned correctly, then additional work will be needed such as filling in gaps with putty or other materials before finishing off your project.

3. Over-Beading: Adding too many beads along an edge can cause them to become visually overpowering and cluttered in appearance; instead strive for a balanced look that showcases each individual bead’s beauty by evenly spacing them out and limiting how many are used at once.

4. Ignoring Detail Around The Beads: Along with taking into account how many beads are added, another mistake to avoid is not paying attention to detail around them – such as adding complementary accents like curves, zig zags and swirls which provide further interest without overwhelming a piece’s main focal point (the beads).

Edge Beading Project Examples

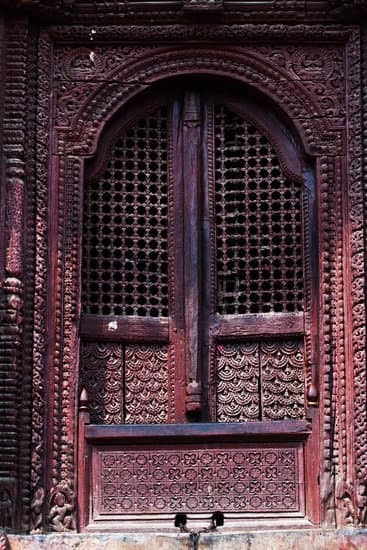

Edge beading is a type of woodworking technique that involves attaching a wooden or metal beading profile along the edge of a project. This is typically used to hide joints and to give an elegant finishing touch to furniture, wall systems and architectural features. Examples of edge beading projects include cabinet doors and inset panels with butt joint details being covered with a beaded edge, including drawer fronts, table tops, mantles and chair rails. Other common uses of edge beading can include picture frames, storage boxes, window casings, doors with applied moldings such as door jambs and baseboards. Edge beading projects are most often done with solid wood, although they can also be used with veneer and laminates. The profiles available for edge beading range from very simple designs to ornate crown molding style ornate flourishes. Edge Beading can also add strength to your piece by reinforcing the joinery. Used on furniture pieces like coffee tables and end tables it can give them durability when using lightweight panels or thin stock.

Conclusion

Edge beading woodworking is a great way to make woodworking projects stand out from the rest. Edge beading takes the natural beauty of wood and enhances it with unique decorative elements. By adding edge beading to furniture, doors, frames, cabinets and more, you can showcase the natural beauty of your project while also creating a truly unique look and feel. With its intricate designs and ornate detailing, edge beading is sure to make any woodworking project stand out from the crowd in a subtle yet stunning way. And best of all, you can customize edge beading to suit your own taste so that no two pieces are ever alike! Whether you’re into traditional or modern styles, edge beading is surely a great way to bring new life and style into any woodworking project.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.