Woodworking vise is a fundamental tool in any woodshop, designed to hold materials securely in place during various woodworking tasks. Whether you’re a professional carpenter or an enthusiastic DIYer, a woodworking vise is an essential accessory that can significantly enhance your efficiency and precision. In this article, we will explore the importance and versatility of woodworking vises, understanding their purpose and function, as well as the different types available in the market.

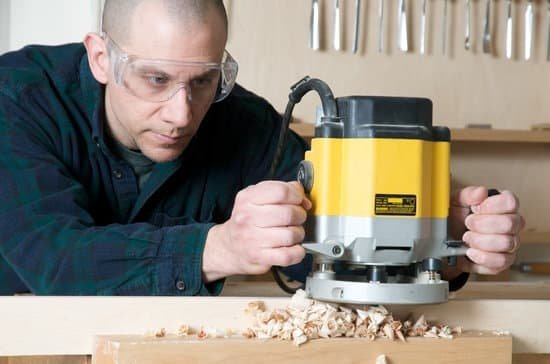

Woodworking vises play a crucial role in providing stability, allowing woodworkers to work on their projects without worrying about the material slipping or moving unexpectedly. They are primarily used for holding workpieces firmly while performing tasks like sawing, planing, routing, sanding, or drilling. With the help of a woodworking vise, woodworkers can achieve precise cuts and shapes with greater control and accuracy.

Beyond its primary function of securing workpieces, woodworking vises also offer versatility in terms of design and functionality. Different types of vises cater to specific tasks and workbench setups. Bench vises are typically mounted on the front or side of a workbench and provide excellent clamping strength for general woodworking activities.

Leg vises are traditionally used for larger projects that require heavy-duty clamping power. Front vises are commonly found on modern workbenches and allow for quick adjustments and flexible positioning.

In the following sections of this article, we will delve deeper into demystifying the purpose and function of woodworking vises, exploring their construction and design nuances as well as learning how to choose the right vise for your projects based on various factors such as size, grip capacity, and mounting options. Additionally, we will provide step-by-step guidelines on installing a woodworking vise onto your workbench and offer creative ways to utilize this versatile tool in different woodworking projects.

Demystifying the Woodworking Vise

A woodworking vise is an essential tool for any woodworker, whether they are a beginner or experienced craftsman. It is used to securely hold pieces of wood in place during various woodworking tasks. The primary purpose of a woodworking vise is to provide stability and prevent movement while shaping, cutting, drilling, or sanding wood.

One of the main functions of a woodworking vise is to hold the workpiece firmly in place so that the woodworker can focus on their craft without having to worry about slippage or movement. This allows for greater precision and accuracy in cuts and shaping. A vise also helps to reduce the risk of accidents by providing stability and reducing the chances of the workpiece shifting unexpectedly.

There are several types of woodworking vises available, each with its own unique purpose and function. The most common types include bench vises, leg vises, and front vises. Bench vises are typically mounted at the front or side of a workbench and are designed for general-purpose use. Leg vises are often used for larger projects where added clamping force is required. Front vises are similar to bench vises but are mounted on the front face of a workbench instead.

In summary, a woodworking vise is an indispensable tool that plays a crucial role in ensuring stability, precision, and safety in woodworking projects. Whether you are cutting, shaping, drilling, or sanding wood, having a dependable vise will greatly enhance your woodworking experience by securely holding your workpieces in place. With different types available to suit various project needs and requirements, it’s essential to choose the right woodworking vise that fits your specific needs.

The Different Types of Woodworking Vises

Woodworking vises come in various types, each serving different purposes and providing unique functionalities. Understanding the different types of woodworking vises will help you select the right one for your specific needs and ensure efficient and precise woodworking projects.

- Bench Vises: Bench vises are the most common type of woodworking vise and are typically mounted on a workbench. They consist of two jaws, one fixed and one movable, that tighten together to hold the workpiece securely in place.

Bench vises are versatile and can be used for a wide range of tasks such as sawing, planing, drilling, sanding, and shaping. They provide stability and support while allowing you to work on the surface of the workpiece without obstruction. - Leg Vises: Leg vises are a traditional type of woodworking vise that are attached to one leg of a workbench. They have a solid wooden jaw that is clamped down onto the workpiece using a metal screw or lever mechanism. Leg vises excel at holding large and irregularly shaped objects securely in place. Their design allows you to apply pressure from multiple angles, making them ideal for joinery work such as mortising or dovetailing.

- Front Vises: Front vises, also known as face vises or shoulder vises, are installed on the front edge of a workbench facing toward the woodworker. They feature two jaws-one fixed near the edge of the bench and another movable-enabling you to grip pieces with precision from both sides.

Front vises are particularly useful for working on large panels or boards where additional support is needed. They provide excellent control over holding power and allow for perpendicular clamping.

By understanding the different types of woodworking vises available, you can choose the one that best suits your needs based on your projects’ requirements and personal preferences. Whether it’s versatility (bench vise), specialized joinery (leg vise), or improved control (front vise), selecting the right type of woodworking vise will enhance your woodworking experience and enable you to achieve precise, high-quality results.

Exploring the Construction and Design of Woodworking Vises

Woodworking vises are an essential tool for any woodworker, providing a secure and stable grip on workpieces during various woodworking tasks. Understanding the construction and design of woodworking vises is crucial in order to make informed decisions when selecting the right vise for your projects. In this section, we will explore the different components and features that make up a woodworking vise.

Components of a Woodworking Vise

A typical woodworking vise consists of several key components that work together to provide stability and clamping force. These include:

- Jaws: The jaws are the primary gripping surface of the vise that hold the workpiece securely in place. They can be made from metal or wood, with some vises offering replaceable jaw inserts for added versatility.

- Screws: The screws are responsible for moving the jaws towards each other or apart to clamp or release the workpiece. While older vises may use wooden screws, modern vises often feature metal screws with large threads for increased strength and durability.

- Guide rods: Guide rods ensure smooth and straight movement of the jaws by keeping them aligned as they move back and forth. They are usually attached to the stationary part of the vise and run through holes in both jaws.

Types of Woodworking Vises

Woodworking vises come in various types, each designed to serve specific purposes and accommodate different woodworking techniques. Some common types include:

- Bench Vises: These vises are typically mounted on a workbench and feature jaws that open horizontally. Bench vises are versatile and suitable for a wide range of woodworking tasks.

- Leg Vises: Leg vises are larger than bench vises and have one jaw attached to a leg or side apron of a workbench while the other moves vertically along a guide screw or guide rods.

- Front Vises: Also known as face vises, front vises are mounted on the front edge of a workbench and have one stationary jaw and one movable jaw that slides along a screw. They are often used for edge planing and jointing.

Whether you are working on small scale projects or large furniture pieces, understanding the construction and design of woodworking vises is vital in selecting the right vise that suits your specific needs. By considering factors such as the type of woodworking tasks you intend to perform and the materials you will be working with, you can ensure that your chosen vise will provide the necessary stability and usability to enhance your woodworking experience.

How to Choose the Right Woodworking Vise for Your Projects

When it comes to woodworking, having the right tools is essential to ensure successful and efficient projects. One crucial tool that every woodworker should consider is a woodworking vise. However, with so many options available on the market, it can be overwhelming to choose the right one for your specific projects. In this section, we will discuss the factors you need to consider when selecting a woodworking vise.

The first factor to consider is the type of woodworking vise that best suits your needs. There are three main types: bench vises, leg vises, and front vises. Bench vises are attached to the top surface of the workbench and provide stability and support for various woodworking tasks.

Leg vises are connected to one of the legs of the workbench and allow you to clamp larger workpieces securely. Front vises are installed at the front of the workbench and provide excellent clamping capabilities for smaller pieces.

Another important factor to consider is the size and capacity of the vise. The size refers to the width of the jaws, which determines how large of a workpiece you can hold. Consider both your current project requirements as well as any potential future projects when choosing a jaw width. Additionally, pay attention to the maximum opening capacity or throat depth of the vise, which determines how deep you can reach into a piece when clamping.

Lastly, take into account the material and construction quality of the vise. Look for sturdy materials like cast iron or steel that offer durability and strength. A well-built woodworking vise will be able to withstand heavy-duty use without compromising its functionality.

By considering these factors – type, size/capacity, and material/construction quality – you can choose a woodworking vise that perfectly suits your needs and preferences for your woodworking projects. Remember that investing in a high-quality vise will greatly enhance your work efficiency while ensuring precise results for years to come.

Step-by-Step Guide on Installing and Mounting a Woodworking Vise to Your Workbench

Gather the Necessary Tools and Materials

Before you begin installing and mounting a woodworking vise to your workbench, it is important to ensure that you have all the necessary tools and materials. Here are some items you will need for this project:

- Woodworking vise: Choose a vise that suits your needs and the type of woodworking projects you undertake. Consider factors such as size, weight capacity, and the type of jaws.

- Workbench: Ensure that your workbench is sturdy enough to support the weight of the vise and can withstand the pressure exerted during woodworking tasks.

- Mounting hardware: This may include bolts, washers, nuts, and any additional hardware needed to attach the vise securely to your workbench.

- Power drill: You will need a power drill with appropriate drill bits for drilling holes into your workbench.

- Screwdriver or wrench: Depending on the type of mounting hardware used, you may need a screwdriver or wrench for tightening bolts.

- Measuring tape or ruler: Accurate measurements are crucial during installation, so having a measuring tape or ruler on hand is essential.

Prepare Your Workbench

The first step in installing a woodworking vise is to prepare your workbench. Start by identifying the ideal location for your vise based on your preference and woodworking needs. It is generally recommended to mount it near one end of the workbench for better stability.

Once you have determined the placement, mark where you will be drilling holes for mounting. Use a measuring tape or ruler to ensure accurate spacing between the drilled holes. Keep in mind that some vises require additional clearance space around them for full operation.

Next, use a power drill equipped with an appropriate drill bit size depending on your mounting hardware. Start by drilling pilot holes in each marked location on your workbench. Pilot holes help guide screws into place smoothly without splitting the wood.

Attach the Woodworking Vise

After you have pre-drilled the pilot holes, it is time to attach the vise to your workbench. Place the vise on top of the drilled holes and align the mounting holes of the vise with the pilot holes in your workbench.

Insert bolts through each hole and secure them with washers and nuts. Use a screwdriver or wrench to tighten the bolts securely, ensuring that they are flush with the surface of the vise.

Once you have attached all bolts and tightened them, give your vise a test run to ensure it is stable and secure. Apply pressure to various points of the jaws to assess its stability.

Congratulations. You have successfully installed and mounted a woodworking vise to your workbench. Now you can begin enjoying the benefits of a reliable tool for holding your projects in place while you work.

Unlocking the Potential

Woodworking vises are incredibly versatile tools that can be used for a wide range of woodworking projects. While their primary function is to hold wood securely in place, there are many creative ways that you can use a woodworking vise to enhance your projects and make your work easier.

One creative way to use a woodworking vise is as a third hand. When working on intricate or delicate pieces, it can be challenging to hold everything in place while also using your hands and tools. By using a woodworking vise, you can secure the piece you are working on and have both hands free to manipulate the materials or operate your tools. This not only improves safety but also allows for more precision and control in your work.

Another creative use for a woodworking vise is as a carving or shaping aid. Using clamps or screws, you can attach wooden blocks or jigs to the jaws of the vise, creating custom profiles or shapes that can be used as guides for carving or shaping wood. This technique not only ensures consistency in your work but also provides additional support and stability during these processes.

Additionally, a woodworking vise can serve as an extra set of hands when assembling large or complex projects. By securing one piece in the vise, you can easily align and attach other pieces without worrying about them shifting or moving during the assembly process. This helps ensure precise joinery and eliminates any potential frustration that may come from trying to hold multiple pieces together while also using tools such as drills or screwdrivers.

Overall, by thinking outside the box and exploring different ways to utilize a woodworking vise, you can unlock its full potential and maximize its usefulness in various woodworking projects. From acting as an extra set of hands to serving as a carving aid, the possibilities are endless when it comes to getting creative with this essential tool.

Maintenance Tips for Keeping Your Woodworking Vise in Prime Condition

Woodworking vises are essential tools in any woodworker’s workshop, providing a secure and stable grip on the workpiece during various woodworking projects. To ensure optimal performance and longevity, it is crucial to properly maintain and care for your woodworking vise. In this section, we will discuss some maintenance tips that will help you keep your woodworking vise in prime condition.

One important aspect of maintaining a woodworking vise is keeping it clean and free from debris such as dirt, sawdust, and shavings. Regularly cleaning the vise will prevent these materials from accumulating inside the jaws or mechanisms, which can affect its overall functionality. Use a brush or compressed air to remove any loose debris, and wipe down the surfaces with a clean cloth.

Another key aspect of maintenance is lubrication. Applying lubricant to the moving parts of the woodworking vise will help reduce friction and ensure smooth operation. It is recommended to use a lubricant specifically designed for woodworking tools, such as silicone spray or dry film lubricant. Avoid using grease or oil-based lubricants as they can attract dust and create a sticky residue.

Inspecting the condition of the woodworking vise regularly is also important. Check for any signs of wear or damage such as bent jaws, loose screws, or misaligned components. If you notice any issues, address them promptly to prevent further damage and ensure safe operation. Tighten any loose screws or bolts, realign misaligned components, and replace damaged parts if necessary.

| Maintenance Tip | Description |

|---|---|

| Cleaning | Regularly remove debris and clean surfaces with a brush or compressed air. |

| Lubrication | Apply woodworking-specific lubricants to moving parts to reduce friction and ensure smooth operation. |

| Inspection | Regularly inspect the vise for wear or damage, addressing any issues promptly. |

By following these maintenance tips, you can keep your woodworking vise in prime condition for years to come. Remember that proper maintenance not only prolongs the lifespan of your vise but also ensures optimal performance and safety during woodworking projects. Investing a little time and effort into maintaining your woodworking vise will pay off in the long run and contribute to a more enjoyable woodworking experience.

Enhancing Your Woodworking Experience

Woodworking vises are essential tools in any woodworking workshop, providing stability, security, and versatility when working with wood. While these vises are effective on their own, there are accessories and add-ons available that can further enhance your woodworking experience. These accessories and add-ons can expand the capabilities of your vise and make your woodworking tasks more efficient and precise.

One popular accessory for woodworking vises is the vise jaw pad. These pads are usually made from materials such as rubber or leather and attach to the jaws of the vise with adhesive or magnets. Vise jaw pads provide a softer surface for clamping delicate or easily marred pieces of wood. They prevent workpieces from getting damaged or slipping during the clamping process.

Another useful add-on for woodworking vises is a bench dog. Bench dogs are pegs that fit into holes drilled into the workbench surface. They act as stops to hold the workpiece in place while you’re working on it. With bench dogs, you can effectively secure larger pieces of wood without relying solely on the vise jaws. This allows for greater stability and control during woodworking tasks.

In addition to vise jaw pads and bench dogs, there are other accessories and add-ons available for specific purposes. For example, some woodworking vises come with auxiliary plates that provide extra support when clamping thin or narrow workpieces. There are also quick-release mechanisms available that allow for faster adjustment and repositioning of the vise jaws.

These accessories and add-ons not only improve the functionality of your woodworking vise but also increase efficiency by saving time and reducing potential errors. So before you start your next woodworking project, consider investing in these accessories to enhance your woodworking experience and achieve better results.

| Accessory/Add-On | Description |

|---|---|

| Vise Jaw Pad | A pad made from rubber or leather that attaches to the vise jaws, providing a softer clamping surface for delicate workpieces. |

| Bench Dog | A peg that fits into holes drilled in the workbench surface, acting as a stop to hold the workpiece in place while working on it. |

| Auxiliary Plate | An additional plate that provides extra support when clamping thin or narrow workpieces. |

| Quick-Release Mechanism | A mechanism that allows for faster adjustment and repositioning of the vise jaws. |

Conclusion

In conclusion, a woodworking vise is an essential tool for any woodworker. Its importance and versatility cannot be overstated. By securely holding the workpiece in place, it allows for precise and accurate cuts, ensuring that each piece is crafted with the utmost precision.

Throughout this article, we have demystified the woodworking vise by understanding its purpose and function. We have explored the different types of woodworking vises available, including bench vises, leg vises, and front vises. The construction and design of these vises have been examined to provide a comprehensive understanding of their capabilities.

Choosing the right woodworking vise for your projects is crucial. Factors such as size, material, and mounting options should be carefully considered to ensure optimal performance. Additionally, we have provided a step-by-step guide on how to install and mount a woodworking vise to your workbench.

Furthermore, we have unlocked the potential of woodworking vises by showcasing creative ways to use them in various woodworking projects. From holding irregularly shaped workpieces to assisting in joinery tasks, these vises are invaluable in expanding the possibilities of what can be achieved in your workshop.

To keep your woodworking vise in prime condition, regular maintenance is necessary. Simple cleaning and lubrication can go a long way in extending the lifespan of your vise and ensuring smooth operation.

Lastly, we have discussed accessories and add-ons that enhance your woodworking experience with a vise. Whether it’s using padded jaw covers for delicate workpieces or utilizing quick-release mechanisms for efficient positioning, these additions can greatly improve efficiency and convenience.

Frequently Asked Questions

Do I need a woodworking vise?

Whether or not you need a woodworking vise depends on your specific woodworking needs and preferences. A woodworking vise is a valuable tool for securely holding pieces of wood in place, providing stability and control during various woodworking tasks. If you frequently work with wooden materials, a woodworking vise can greatly enhance your productivity and precision.

It allows you to firmly grip the workpiece, preventing it from slipping or moving while you saw, chisel, plane, or carve. However, if you primarily engage in smaller woodworking projects that don’t require heavy-duty clamping, you may find other alternatives like clamps or vises built into certain tools sufficient for your needs.

Why do we use a vice on a woodworking bench?

Using a vice on a woodworking bench serves several purposes that greatly aid in woodworking tasks. One key reason is to provide a secure and stable work surface where the wood can be clamped down while being worked upon. This prevents movement or shifting of the wood piece during cutting, shaping, or joining operations, ensuring accurate and consistent results.

The vice acts as an extra set of hands, gripping the material tightly while leaving both your hands free to work with tools safely and efficiently. Additionally, having a vice allows you to hold larger or irregularly shaped pieces that may be cumbersome to handle manually or with other types of clamps.

What is the difference between a woodworking vise and a metal vice?

While both types of vises are functionally similar in terms of gripping and holding objects firmly in place, there are some differences between a woodworking vise and a metal vice that cater to their respective applications. A key difference lies in their construction materials and design features. Woodworking vises are typically made with wooden jaws that help protect delicate wooden surfaces from damage during clamping.

They often have larger openings to accommodate thicker material or odd shapes commonly found in woodwork. On the other hand, metal vices are usually constructed with steel jaws designed for more heavy-duty applications involving metalworking tasks like cutting pipes, bending metal bars, or securing metal workpieces for welding. Additionally, metal vices often have a swivel base that allows for better positioning and rotating objects, while woodworking vises tend to be fixed in place on the bench.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.