Woodwork technology, also known as woodworking, is the art and craft of creating objects from wood. It involves using various tools and techniques to shape and join wood to create furniture, decorative items, and much more.

In this article, we will explore the fundamentals of woodwork technology, its history, importance in today’s world, tools and equipment used, types of wood utilized, the process of woodwork technology from raw material to finished product, applications in various industries, and future trends and advancements.

The history of woodwork technology dates back centuries, with ancient civilizations using primitive tools to carve and construct wooden objects. Over time, modern techniques and technology have revolutionized the field of woodworking, making it an essential part of various industries such as construction, manufacturing, and even artistry.

In today’s world, woodwork technology plays a crucial role in providing high-quality products for everyday use. Whether it’s creating durable furniture for homes or crafting intricate designs for interior decoration, the skills and knowledge of woodworking are indispensable. This article aims to provide an in-depth look at woodwork technology to understand its significance in our daily lives and its impact on various fields.

History of Woodwork Technology

Woodwork technology has a rich history that dates back to ancient times. From the primitive tools used by early civilizations to the modern machinery and techniques utilized today, the evolution of woodwork technology has been nothing short of remarkable. Ancient woodworkers relied on basic hand tools such as chisels, saws, and axes to shape and manipulate wood into functional objects for everyday use. These early techniques laid the foundation for the development of more advanced methods in later centuries.

As civilizations advanced, so did the methods and tools used in woodwork technology. The Middle Ages saw the emergence of carpentry guilds and specialized woodworking trades, leading to refined craftsmanship and intricate wood carvings in architecture and furniture. The Industrial Revolution brought about a major shift in woodwork technology with the invention of steam-powered machines, enabling mass production and increased efficiency in woodworking processes.

Today, modern woodworking techniques have continued to evolve with the introduction of innovative equipment such as CNC routers, laser cutters, and 3D printers. These technologies have revolutionized the way wood is processed and manufactured, allowing for greater precision, customization, and speed in production.

Despite these advancements, traditional handcrafted woodworking still holds its place in contemporary design, blending old-world craftsmanship with new-age technology. The history of woodwork technology serves as a testament to human ingenuity and our enduring relationship with this versatile natural material.

Importance of Woodwork Technology in Today’s World

Woodwork technology plays a crucial role in today’s world for numerous reasons. One of the primary reasons for its importance is its contribution to the economy. Woodwork technology encompasses various industries such as furniture, construction, and manufacturing, which are significant contributors to the global economy. These industries rely on woodwork technology to create high-quality products that meet the demands of consumers.

Additionally, woodwork technology is important for environmental sustainability. With an increasing focus on sustainable practices, the use of wood from responsibly managed forests has become essential. Woodwork technology allows for the efficient utilization of wood resources while promoting reforestation and conservation efforts. Moreover, advancements in woodwork technology have led to the development of eco-friendly materials and processes that minimize waste and reduce environmental impact.

Furthermore, woodwork technology is essential for preserving traditional craftsmanship and cultural heritage. Woodworking techniques and practices have been passed down through generations, contributing to the rich history and culture of different societies around the world. By incorporating modern innovations with traditional woodworking methods, woodwork technology helps uphold these cultural legacies while meeting contemporary needs. Overall, the importance of woodwork technology in today’s world extends beyond its economic and environmental significance, encompassing cultural preservation and innovation.

Tools and Equipment Used in Woodwork Technology

Basic Hand Tools

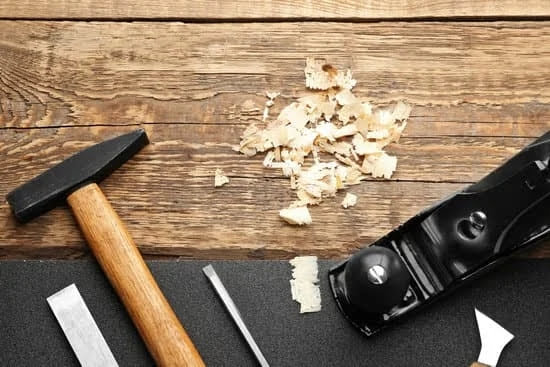

Woodwork technology requires a wide array of tools and equipment to carry out various tasks. From simple hand tools such as chisels, hammers, saws, and screwdrivers to more complex power tools like drills, sanders, and routers, each tool serves a specific purpose in the woodworking process. These tools are essential for cutting, shaping, joining, and finishing wood to create functional or decorative items.

Woodworking Machinery

In addition to hand tools, woodwork technology often involves the use of machinery for larger-scale projects. This includes table saws, band saws, jointers, planers, and lathes. These machines are designed to make the woodworking process more efficient and precise. They enable woodworkers to work with larger pieces of wood and achieve more intricate designs.

Safety Equipment

Safety is a crucial aspect of woodwork technology due to the potential hazards involved in working with sharp tools and heavy machinery. Safety equipment such as goggles, ear protection, dust masks, and gloves are essential for protecting workers from injury or illness. Dust collection systems are also important for maintaining clean air in the workspace and preventing respiratory issues caused by wood particles.

Woodwork technology encompasses the use of traditional hand tools as well as modern machinery to transform raw wood into finished products. Understanding these tools and equipment is essential for anyone interested in pursuing woodworking as a hobby or profession.

Types of Wood Used in Woodwork Technology

Woodwork technology makes use of a variety of wood types, each with its own unique properties and characteristics that make it suitable for different applications. Whether for construction, furniture making, or artistic creations, the type of wood used can greatly impact the final product.

Hardwood

Hardwood, such as oak, maple, and cherry, is known for its durability and strength. It is often used in high-quality furniture making, flooring, and cabinetry due to its resistance to wear and tear. The rich and attractive grain patterns of hardwood also make it a popular choice for decorative woodworking projects.

Softwood

Contrary to its name, softwood such as pine, cedar, and fir is not necessarily softer than hardwood. Softwood is commonly used in construction due to its availability and affordability. It is also widely used in carpentry projects where strength and durability are less important compared to aesthetic considerations.

Engineered Wood

Engineered wood products such as plywood and particleboard are created by binding together wood fibers with adhesives under heat and pressure. These materials offer greater stability and uniformity compared to natural solid wood, making them suitable for structural purposes in construction and cabinetry.

Understanding the characteristics of each type of wood is crucial in the field of woodwork technology as it allows craftsmen to select the most appropriate material for their specific project requirements. Whether strength, appearance, or cost-effectiveness is the primary consideration, choosing the right type of wood is essential in achieving successful woodworking outcomes.

The Process of Woodwork Technology

Woodwork technology involves the process of transforming raw wood materials into finished products through various techniques and tools. Below are the key stages involved in the process of woodwork technology:

- Selection of raw material: The first step in woodwork technology is selecting the right type of wood for the intended project. This could be hardwood, softwood, or engineered wood, depending on the desired characteristics and end-use of the product.

- Preparation of raw material: Once the wood is selected, it needs to be processed to remove any imperfections such as knots, bark, or irregularities. This may involve cutting, planing, or jointing the wood to achieve a smooth and uniform surface.

- Joinery and shaping: In this stage, the prepared wood pieces are joined together using techniques such as dovetail joints, mortise and tenon joints, or adhesives. Shaping of the wood can also occur during this stage using tools like routers or chisels to create intricate designs or patterns.

Throughout these stages, precision and accuracy are crucial in achieving high-quality finished products. Woodworkers often use a variety of hand tools and power tools such as saws, drills, sanders, and lathes to carry out these processes efficiently.

Furthermore, finishing techniques such as staining, varnishing, or painting are applied to enhance the appearance and durability of the final product before it is ready for its intended use. What is woodwork technology without its meticulous attention to detail at every step of the process?

Applications of Woodwork Technology in Various Industries

Woodwork technology is used in various industries for a wide range of applications. Here are some of the industries where woodwork technology plays a crucial role:

1. Furniture Industry:

The furniture industry relies heavily on woodwork technology for the production of various types of furniture, such as chairs, tables, cabinets, and beds. Woodwork technology allows for the customization and mass production of furniture pieces to meet the diverse needs and preferences of consumers.

2. Construction Industry:

Woodwork technology is also essential in the construction industry for creating structural components, such as doors, windows, trim work, and moldings. Additionally, woodwork technology is used in architectural detailing and decorative elements that enhance the aesthetic appeal of buildings.

3. Musical Instrument Manufacturing:

Musical instrument manufacturers utilize woodwork technology to craft instruments such as guitars, violins, pianos, and drum sets. The precision and craftsmanship involved in woodwork technology are crucial for producing high-quality instruments with superior acoustic properties.

4. Art and Crafts Industry:

Artisans and craftsmen rely on woodwork technology to create intricate carvings, sculptures, jewelry boxes, and other artistic pieces. These handmade wooden items showcase the creativity and skillful artistry achievable through woodwork technology.

By understanding the various applications of woodwork technology across different industries, it becomes clear that this field plays a significant role in shaping our everyday lives through the products we use and interact with regularly. Whether it’s furniture in our homes or structural elements in buildings, woodwork technology continues to be an essential aspect of modern industrial processes.

Future Trends and Advancements in Woodwork Technology

In conclusion, woodwork technology has played a crucial role in shaping the world as we know it. From ancient techniques to modern advancements, the art of working with wood has evolved significantly over the years. The importance of woodwork technology in today’s world cannot be overstated, as it is used in various industries such as construction, furniture making, and interior design.

As technology continues to advance, so does woodwork technology. The future trends and advancements in this field are promising, with the integration of digital tools and automation making the process more efficient and precise. This means that woodwork technology will continue to be a fundamental aspect of many industries for years to come.

The types of wood used in woodwork technology will also evolve as sustainable practices become more prevalent. With an increasing focus on environmental conservation, there will likely be a shift towards using eco-friendly and renewable sources of wood. Overall, the future of woodwork technology is bright, with innovative solutions and sustainable practices leading the way for continued progress in this field.

Frequently Asked Questions

What Are the Examples of Woodwork?

Woodwork examples include furniture making, cabinet making, carving, wood turning, and carpentry. These activities involve shaping and joining wood to create functional or decorative objects.

What Technology Is Used for Carpentry?

Carpentry utilizes a variety of hand tools such as saws, chisels, planes, and measuring devices. Power tools like drills, sanders, and routers are also commonly used in carpentry work. Additionally, modern technology has introduced computer-aided design (CAD) software for designing projects and CNC (computer numerical control) machinery for precision cutting and shaping of wood.

What Is Considered Woodwork?

Woodwork encompasses a wide range of activities related to working with wood. This can include everything from simple woodworking projects for beginners like building a birdhouse or picture frame to complex construction projects such as building houses, bridges, or boats.

Woodworking can also involve creating intricate designs through carving or woodturning for artistic purposes. Ultimately, any endeavor involving the manipulation of wood can be considered a form of woodwork.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.