Woodworking often requires the precise cutting of angles to create everything from furniture to decorative pieces. In this article, we will explore how to cut angles in woodworking, covering a range of topics from the essential tools needed to techniques for cutting common and complex angles. Understanding the importance of accurate angles and how to achieve clean and precise cuts are key elements that all woodworkers should master.

Accurate angles are crucial in woodworking as they ensure that pieces fit together perfectly, creating a strong and visually appealing finished product. Whether you are working on a simple picture frame or a complex piece of furniture, mastering the art of cutting angles is essential for any woodworker. We will discuss the important role that understanding angles plays in achieving professional results and provide tips for avoiding common mistakes.

To begin our exploration, we will cover the essential tools needed for cutting angles in woodworking. From traditional hand tools to power tools, having the right equipment can make all the difference in achieving accurate cuts. Whether you are a beginner looking to expand your woodworking skills or an experienced woodworker seeking to refine your techniques, this article will provide valuable insights into mastering the art of cutting angles in woodworking projects.

Understanding the Importance of Accurate Angles in Woodworking Projects

Accurate angles are crucial in woodworking projects as they contribute to the overall quality and aesthetics of the final product. Whether you are constructing a simple picture frame or building a complex piece of furniture, cutting angles precisely is essential for ensuring structural integrity and visual appeal. Incorrectly cut angles can result in uneven joints, gaps, and unstable constructions, which can compromise the durability and functionality of your woodworking project.

To achieve accurate angles in woodworking, it is essential to use the right tools and techniques. Whether you are working with common angles such as 45 degrees and 90 degrees, or tackling more complex angles, precision is key to achieving professional-looking results. The use of tools such as miter saws, table saws, and hand saws, combined with proper measurement and marking techniques, is vital for cutting angles with precision.

When cutting angles in woodworking projects, it’s important to pay attention to details such as grain direction, wood species characteristics, and potential wood movement. These factors can affect how the wood responds to cutting and can influence the accuracy of your cuts. By understanding these considerations, woodworkers can anticipate potential challenges when cutting angles and make adjustments accordingly.

- Use high-quality measuring tools such as protractors, speed squares, or adjustable bevel gauges.

- Consider using a miter saw or compound miter saw for accurate angle cuts.

- Opt for sharp blades and appropriate cutting speeds to minimize tear-out on wood surfaces.

- Secure workpieces firmly using clamps or workbench stops to prevent movement during cutting.

- When dealing with highly visible areas such as mitered corners on furniture pieces or decorative moldings, consider practicing on scrap pieces before making cuts on final materials.

By following these tips and techniques for achieving precise angles in woodworking projects, woodworkers can ensure that their creations not only look professional but also stand the test of time. With practice and attention to detail during the angle-cutting process. woodworkers will be able to elevate their craftsmanship and take their woodworking projects to the next level.

Essential Tools for Cutting Angles in Woodworking

When it comes to woodworking, cutting angles accurately is a crucial skill that every woodworker needs to master. To achieve precise and clean cuts, it is essential to have the right tools at your disposal. Whether you are a beginner or an experienced woodworker, having the proper tools for cutting angles can make a significant difference in the quality of your work.

Power Tools

One of the essential power tools for cutting angles in woodworking is a miter saw. This versatile tool allows woodworkers to make accurate crosscuts and miter cuts at various angles. It is equipped with a rotating blade that can be adjusted to cut angles ranging from 45 degrees to the left or right, making it ideal for creating picture frames, molding, and other angled cuts.

Another indispensable power tool for cutting angles is a table saw. With the use of a miter gauge or a crosscut sled, woodworkers can achieve precise angle cuts on larger pieces of wood. The table saw’s fence also provides support for straight-line cuts, making it useful for creating bevels and compound miters.

Hand Tools

In addition to power tools, hand tools are also essential for cutting angles in woodworking. A good-quality combination square is invaluable for checking and marking accurate angles on wood pieces before making cuts. A sliding bevel gauge is another handy tool that allows woodworkers to transfer and set specific angles directly onto their workpieces.

Learning how to cut angles in woodworking involves understanding the importance of having the right tools for the job. By investing in quality power and hand tools, woodworkers can ensure that their angle cuts are precise and clean, ultimately leading to professional-looking finished projects.

Techniques for Cutting Common Angles (45 Degrees, 90 Degrees, Etc)

Cutting common angles in woodworking is an essential skill for any woodworker. Whether you are working on a simple DIY project or a more complex woodworking endeavor, understanding how to accurately cut angles is crucial for achieving professional-looking results. In this section, we will explore the techniques for cutting common angles such as 45 degrees and 90 degrees, as well as other frequently used angles in woodworking projects.

When it comes to cutting common angles in woodworking, having the right tools is paramount. A miter saw is one of the most commonly used tools for cutting angles, especially when dealing with 45-degree and 90-degree cuts. This versatile tool allows woodworkers to make precise angled cuts with ease. Additionally, a table saw equipped with a miter gauge can also be used to cut straight and accurate 90-degree angles.

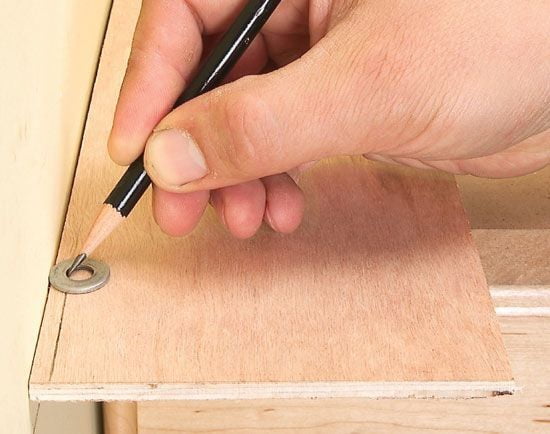

For making accurate 45-degree cuts, an adjustable bevel or combination square can be invaluable. These tools allow woodworkers to mark and measure the desired angle before making the cut. It’s important to use a sharp pencil when marking the angle to ensure precision. Once the angle is marked, use a high-quality handsaw or power saw equipped with an adjustable bevel to make the cut.

Remember, safety should always be a priority when cutting angles in woodworking. Always wear appropriate safety gear such as goggles and ear protection, and ensure that your work area is well-lit and free from obstructions. By following these techniques and safety precautions, you can achieve clean and precise cuts when working with common woodworking angles.

| Common Angle | Recommended Tool |

|---|---|

| 45 degrees | Miter Saw |

| 90 degrees | Miter Saw/Table Saw with Miter Gauge |

Advanced Techniques for Cutting Complex Angles

When it comes to woodworking, there are times when you’ll need to cut complex angles for more intricate projects. While cutting common angles like 45 degrees and 90 degrees is relatively straightforward, cutting complex angles requires more advanced techniques and precision. Here are some tips and techniques for cutting complex angles in woodworking:

- Use of a Miter Saw: A miter saw is an essential tool for cutting complex angles in woodworking. With its ability to pivot in both directions, it allows you to make precise angle cuts. To cut a compound angle, adjust the miter and bevel settings on the saw according to your project’s specifications.

- Utilizing a Table Saw: Another method for cutting complex angles is by using a table saw with a miter gauge or crosscut sled. You can set the angle of the cut by adjusting the miter gauge or sled to the desired angle, allowing for accurate and repeatable cuts.

- Creating Jigs and Templates: For unique or irregular angles, creating jigs or templates can be helpful. These tools can provide a guide for making precise cuts on workpieces with non-standard angles.

Cutting complex angles requires careful planning and execution to achieve accurate results in your woodworking projects. By utilizing the right tools and techniques, you can take your woodworking skills to the next level and tackle more challenging projects with confidence.

Remember that practice makes perfect when mastering the art of cutting complex angles in woodworking. Take the time to familiarize yourself with different methods and tools, as well as experiment with scrap pieces before working on your actual project. With patience and perseverance, you’ll soon become proficient in cutting even the most complex angles with ease.

Tips for Achieving Clean and Precise Cuts

When it comes to woodworking, achieving clean and precise cuts is essential for a professional-looking final product. Whether you are cutting angles for furniture, trim, or any other woodworking project, the quality of your cuts can make a significant difference in the overall outcome. In this section, we will explore some tips and techniques for ensuring that your angle cuts are clean, accurate, and free from imperfections.

One of the most important factors in achieving clean and precise angle cuts in woodworking is using the right tools for the job. A high-quality miter saw or table saw with a reliable fence and miter gauge can make a world of difference in the accuracy of your cuts. Additionally, investing in sharp, high-quality blades specifically designed for cutting wood at different angles can help you achieve cleaner and more precise results.

Another tip for achieving clean and precise angle cuts in woodworking is to take your time and pay attention to detail. Rushing through the cutting process can lead to mistakes and inaccuracies that may compromise the final result. Before making any cuts, double-check the measurements and angle settings on your tools to ensure they are correct. Additionally, using clamps or jigs to secure your workpiece firmly in place can help prevent it from shifting during the cutting process.

Lastly, practicing proper technique is crucial for achieving clean and precise angle cuts in woodworking. This includes maintaining a steady hand while guiding the workpiece through the saw blade, as well as using smooth, even pressure to ensure a consistent cut.

It’s also important to be mindful of safety precautions when operating power tools to avoid accidents or injuries during the cutting process. By incorporating these tips into your woodworking routine, you can improve your ability to cut angles accurately while achieving cleaner and more precise results for your projects.

Safety Precautions When Cutting Angles in Woodworking

Woodworking can be a fulfilling and enjoyable hobby, but it’s important to prioritize safety when working with sharp tools and heavy equipment. When it comes to cutting angles in woodworking, there are specific safety precautions that should always be followed to avoid accidents and injuries. Below are some essential safety tips to keep in mind when cutting angles in woodworking.

Wear Personal Protective Equipment

Before you start any woodworking project that involves cutting angles, make sure to equip yourself with the necessary personal protective equipment (PPE). This includes safety glasses or goggles to protect your eyes from wood particles and flying debris, as well as hearing protection if you’re using power tools. Additionally, wearing a dust mask or respirator is crucial for preventing inhalation of wood dust and other airborne particles.

Secure Your Workpiece Properly

Securing your workpiece is vital for maintaining control and stability during the cutting process. Whether you’re using a miter saw, table saw, or any other cutting tool, ensure that your workpiece is firmly clamped or held in place with a vise to prevent slipping or movement. This will reduce the risk of kickback and accidental contact with the blade, minimizing the potential for accidents.

Follow Tool-Specific Safety Guidelines

Each woodworking tool comes with its own set of safety guidelines provided by the manufacturer. It’s crucial to familiarize yourself with these guidelines and adhere to them at all times. Whether it’s using a push stick on a table saw, adjusting blade guards on a miter saw, or maintaining a safe distance from the cutting area, following tool-specific safety protocols is paramount for preventing injuries while cutting angles in woodworking.

By prioritizing safety precautions such as wearing PPE, securing workpieces properly, and following tool-specific guidelines when cutting angles in woodworking projects, woodworkers can minimize the risk of accidents and create a safe working environment in their workshops. Remember that taking the necessary precautions not only protects you from potential harm but also ensures that your woodworking projects are completed successfully.

Common Mistakes to Avoid When Cutting Angles

When it comes to woodworking, cutting angles is a crucial skill to master. However, there are common mistakes that many beginners make when attempting to cut angles in woodworking projects. By being aware of these mistakes and knowing how to avoid them, you can greatly improve the accuracy and precision of your cuts.

One common mistake to avoid when cutting angles in woodworking is not using the appropriate tools for the job. It’s important to use a high-quality miter saw or table saw with a miter gauge to ensure that your angles are cut with precision. Additionally, using a reliable angle measuring tool such as a speed square or protractor can help you achieve the perfect angle for your project.

Another mistake to avoid is neglecting to properly secure the wood before making your cuts. Failing to secure the wood can result in dangerous kickback or inaccurate cuts. Using clamps or a vise to hold the wood firmly in place will ensure stability and safety while cutting angles.

Finally, one of the most common mistakes when cutting angles in woodworking is rushing through the process. Taking your time and carefully measuring and marking your angles before making any cuts is essential for achieving clean and precise results. By rushing through this step, you may end up with inaccurate angles that can ruin your entire project.

By being mindful of these common mistakes and taking the time to use the right tools, secure your wood properly, and measure accurately, you can avoid errors when cutting angles in woodworking projects.

Project Ideas to Practice Cutting Angles in Woodworking

Woodworking projects that involve cutting angles can be a great way to practice and improve your skills. Not only do they allow you to apply your knowledge of angles and measurements, but they also challenge you to think creatively and problem-solve. Here are a few project ideas that can help you hone your skills in cutting angles in woodworking.

One project idea is to create a wooden picture frame with mitered corners. This will require precision in cutting 45-degree angles on each end of the frame pieces so that they fit together seamlessly. You can then add your finishing touches by sanding, staining, or painting the frame to match your decor.

Another project idea is to build a hexagon-shaped shelf or table. This will test your ability to cut six equal angles to form the sides of the hexagon. It’s a great way to practice cutting and fitting together complex angles while creating a functional piece of furniture for your home.

Lastly, consider making a set of nested wooden storage boxes with angled sides. This project will challenge you to cut multiple angled pieces that fit together snugly to create interlocking boxes. It’s a practical project that will not only enhance your woodworking skills but also provide you with useful storage solutions for small items.

By taking on these types of projects, you’ll have the opportunity to apply what you’ve learned about cutting angles in woodworking while challenging yourself with new techniques and designs. These projects will not only help develop your skills but also give you unique and functional items for yourself or others.

With some creativity and patience, you can transform simple pieces of wood into beautiful and practical creations using what you’ve learned about how to cut angles in woodworking.

Conclusion and Recap of Key Points for Cutting Angles in Woodworking

In conclusion, cutting angles in woodworking is an essential skill that can elevate the quality and precision of your projects. By understanding the importance of accurate angles, using the right tools, and mastering various cutting techniques, woodworkers can achieve impeccable results. Whether you are working on basic 45 or 90-degree angles or tackling more complex cuts, it is crucial to follow safety precautions and avoid common mistakes to ensure a successful outcome.

One key takeaway from this guide is the significance of using the appropriate tools for cutting angles in woodworking. From miter saws to bevel gauges, having the right equipment can make all the difference in achieving clean and precise cuts. Additionally, incorporating advanced techniques for cutting complex angles can enhance your woodworking skills and allow you to take on more challenging projects.

As you continue to hone your skills in cutting angles, consider exploring project ideas that will provide opportunities to practice and perfect this technique. From creating custom frames to crafting unique furniture pieces, there are countless ways to apply your newfound knowledge. With dedication and practice, mastering how to cut angles in woodworking will open up a world of creative possibilities for your future projects.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.