1. Cutting the Joint

The first step is to cut the joint. This is typically done with a miter saw, but can also be done with a hand saw.

2. Drilling the Hole

The next step is to drill the hole. This is typically done with a drill, but can also be done with a hand saw.

3. Inserting the Joint

The next step is to insert the joint. This is typically done with a hammer, but can also be done with your hands.

4. Securing the Joint

The next step is to secure the joint. This is typically done with a screwdriver, but can also be done with your hands.

5. Cutting the Wood

The next step is to cut the wood. This is typically done with a saw, but can also be done with your hands.

A & H Woodworking Alabama 243 Haleyville Al

We are a full-service custom woodworking company that has been in business for over 25 years. We specialize in creating high-quality custom cabinetry, furniture, and other woodworking projects for both residential and commercial customers. We take pride in our work, and we always strive to create the best possible finished product for our clients.

We have a team of experienced and skilled craftsmen who can handle any project, no matter how complex it may be. We also have a wide range of materials and finishes available, so we can create a project that perfectly matches your unique style and needs.

If you’re looking for a quality, custom woodworking company, then please contact us today. We would be happy to discuss your project with you and provide a free estimate.

Cool Woodworking Gifts

In the world of woodworking, there are few things more satisfying than giving a handmade gift. Not only is the gift unique, but it’s also a tangible representation of the time and effort you put into it. If you’re looking for some cool woodworking gift ideas, you’ve come to the right place.

Wooden Pens

Wooden pens are a great way to show off your woodworking skills, and they make great gifts for any occasion. They’re also a great way to use up small scraps of wood, so they’re perfect for the beginning woodworker.

To make a wooden pen, you’ll need a piece of wood at least 3/4″ thick, a pen blank, a drill bit, a coping saw, and a sanding block. Start by drilling a hole in the center of the pen blank with a drill bit that’s the same size as the pen tube. Then, use a coping saw to cut the blank into a rough shape, and sand it down until it’s smooth. Finally, attach the pen tube and cap, and you’re done.

Wooden Bowls

Wooden bowls are another great woodworking project for the beginning woodworker. They’re a bit more challenging to make than wooden pens, but they’re still relatively easy, and the results are well worth the effort.

To make a wooden bowl, you’ll need a piece of wood at least 1″ thick, a bowl blank, a coping saw, a jigsaw, and a sanding block. Start by cutting the blank into a rough shape with a coping saw, and then use a jigsaw to cut out the bowl shape. Sand the bowl until it’s smooth, and then finish it with a coat of sealer or varnish.

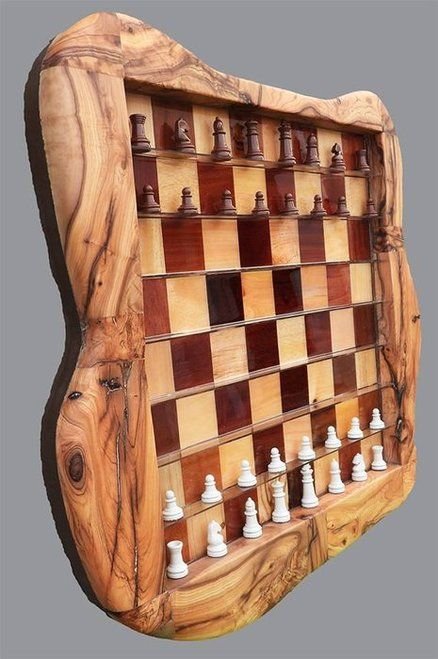

Wooden Chess Board

A wooden chess board is a great project for the experienced woodworker. It’s a bit more challenging than wooden bowls or pens, but the results are well worth the effort.

To make a wooden chess board, you’ll need a piece of wood at least 1 1/2″ thick, a chess board blank, a coping saw, a jigsaw, and a sanding block. Start by cutting the blank into a rough shape with a coping saw, and then use a jigsaw to cut out the chess board shape. Sand the chess board until it’s smooth, and then finish it with a coat of sealer or varnish.

Wooden Picture Frame

A wooden picture frame is a great way to show off your woodworking skills, and it makes a great gift for any occasion.

To make a wooden picture frame, you’ll need a piece of wood at least 1″ thick, a picture frame blank, a coping saw, a jigsaw, and a sanding block. Start by cutting the blank into a rough shape with a coping saw, and then use a jigsaw to cut out the picture frame shape. Sand the picture frame until it’s smooth, and then finish it with a coat of sealer or varnish.

Custom Woodworking Branding Iron

When it comes to woodworking, there is no greater way to show your workmanship than with a branding iron. This custom woodworking branding iron is the perfect way to show your craftsmanship to the world. It is also a great way to show your personal brand. The branding iron is made of high-quality materials and is designed to last. It is also easy to use, making it the perfect tool for any woodworker.

Woodworking Plans Workbench

– The Best Way to Build a Workbench

There are many reasons to build your own workbench. Maybe you don’t have the money to buy one, or you want to build one that is exactly the way you want it. Whatever the reason, there are a few things you need to know before you start.

The first thing you need to do is decide what type of workbench you want to build. There are many different types, each with its own advantages and disadvantages. The most important thing is to make sure the workbench is big enough to fit the tools you plan to use on it.

The next thing you need to do is decide on the size of the workbench. Again, this depends on the tools you plan to use. If you have a lot of large tools, you will need a larger workbench. If you only have a few small tools, you can get away with a smaller workbench.

Once you have decided on the size and type of workbench you want to build, you need to make a plan. This plan will include the dimensions of the workbench, as well as the materials you will need to build it.

The final thing you need to do is build the workbench. This is the easy part. Just follow the plan you created and you will have a workbench that is perfect for you.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.