Introduction to Adjustable Clamps For Woodworking

Adjustable clamps are essential tools for woodworking projects, as they provide a secure hold to make it easier to hold materials in place when cutting or shaping. Clamping is essential to maintain accurate lines and joinery while a project is being built, resulting in a cleaner and more professional-looking end result. Adjustable clamps come in various sizes, shapes, and designs to meet different needs; they may also be made of various materials such as metal or plastic.

Using adjustable clamps for woodworking can help align pieces properly, as well as ensure that parts stay where you want them over the course of the project. It can also assist with attaching two pieces of material together securely before an adhesive is used. The ability to adjust pressure allows the tension placed on the object being worked on to be more exact and precisely tailored to suit whatever it is that’s being worked on.

When selecting adjustable clamps for woodworking projects, there are several key considerations to keep in mind. For example, consider the size and type of objects being worked on; smaller adjustments may need smaller clamps while larger pieces require broader ones with appropriately sized jaws. Choose clamping systems based on common measurements that are going to come up within different projects (e.g., timber sizes) so there won’t be any mismatches between parts when trying to use existing supplies from one job for another. Larger adjustable desktop clamps can also be used as an integral part of workbench set-ups so that multiple items can be held securely together during glue-ups or sanding processes ” an extremely useful feature for woodworkers with limited bench space who want reliable performance during these activities without taking up too much room on their work surface areas.

Types Of Adjustable Clamps For Woodworking

Adjustable clamps are a must-have for anyone who works with wood. They help hold pieces of wood together for gluing or joining, provide stability for larger projects, and help keep pieces of wood aligned. Let’s look at some of the different types of adjustable clamps available for woodworking and the advantages, disadvantages, and uses of each type.

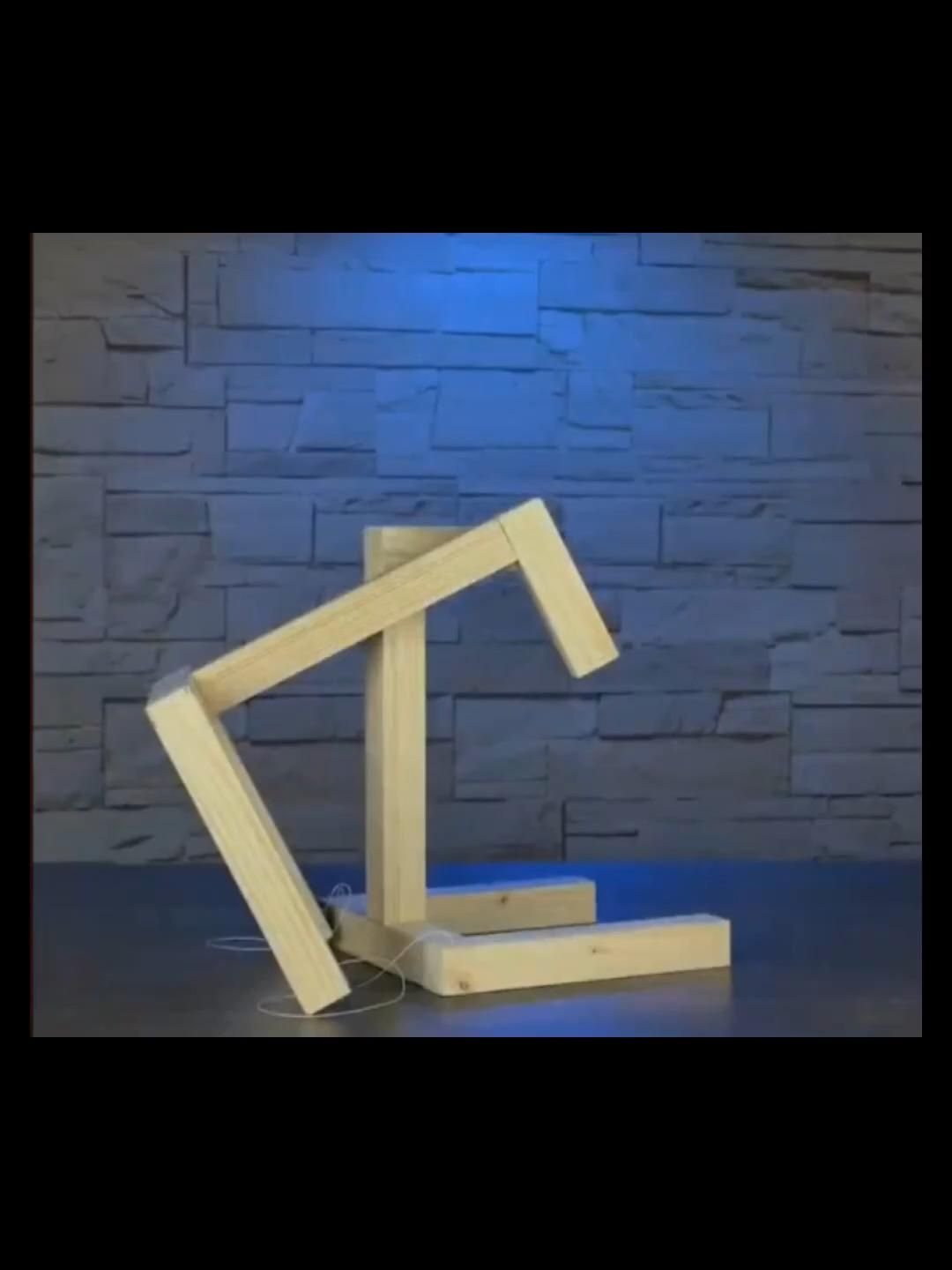

One type is an L-clamp. This simple design provides strong clamping force while still being easy to adjust and use. Advantages of using an L-Clamp include: they are inexpensive; they produce great even pressure around equally sized objects; they are capable of very tight clamping force; and they can be used on a variety of shapes due to their generous jaw capacity. Disadvantages include: they do not provide enough support for large pieces of wood; they easily warp if left in place too long; and they can have difficulty providing adequate grip on slippery surfaces. Uses include: gluing boards together, holding door frames in place while nailing, keeping mouldings in line while cutting, etc..

Another type is bar clamps. These feature a long bar that allows you to move the jaws quickly into position along with adjustable handles for fine adjustments. Advantages of using a bar clamp includes: great versatility because you can easily adjust your fit with its long reach; allows for even clamping pressure over larger area than other clamps; can be bent or extended as needed for odd projects or harder-to-reach areas Disadvantages include: not suitable for delicate tasks due to the amount of power it exerts; two handed operation is needed when facing considerable resistance from the material being secured. Uses including using them on large cabinet structures, laminating panels together, fixing deck boards in place while keeping them even at each end, etc..

In conclusion, adjustable clamps are an essential tool when working with wood that come in many shapes and sizes depending on your project needs. Ensure you know what kind best fits your task before going any further by weighing up various factors such as price point, shape & size limits and their respective advantages & disadvantages compared to alternative options before proceeding with purchasing the right clamp!

Step-By-Step Guide To Using Adjustable Clamps For Woodworking

Adjustable clamps are essential woodworking tools, making it easier to assemble project pieces and ensuring a secure, long-lasting result. It is important to choose the right clamp size and type for each particular application.

To use adjustable clamps to join two pieces of wood together:

1. Start by measuring the distance between the pieces you need to join and determine the size of the clamp needed for the job.

2. Select an adjustable clamp that’s wide enough for your project but still easy to adjust.

3. Place the two pieces of wood you’re joining together in a way that makes access to both ends for clamping easy.

4. Tighten one end of the clamp as far as it will go and then adjust the other end with a screwdriver or allen key until it meets ” but does not exceed -the other side (this will create a tight fit).

5. Once both sides have been set securely, use your quick release lever or thumbscrews on each side of the clamp to tighten further if required and ensure a secure joint between your pieces of wood.

6. Finally, check that your joint is secure, with no gaps present -congratulations, you have successfully joined two pieces together using an adjustable clamp!

Storage Solutions For Adjustable Clamps For Woodworking

When it comes to storing your adjustable woodworking clamps, there are a few different options available to you. The most popular and efficient way is by using racking systems. There are many different kinds of racking systems you can purchase that are specifically designed to securely store your clamps. These systems allow you to easily organize them and also make use of vertical space if necessary. Additionally, some of these racks not only keep your clamps organized, but also keep them safe from dirt and damage while they are in storage.

Clip-on wall racks are another great storage solution for adjustable clamps for woodworking. This type of system is super easy to install and requires no additional support other than screwing the clips into the wall. It’s great because it allows you to easily hang the clamps on one side while possessing the ability to quickly access them from the other side. You could even create a custom design or personal logo with your clip-ons to add a personalized touch

For those who prefer a portable storage solution for their adjustable clamps for woodworking then an adjustable clamp carrying case may be just what you need! These cases make travel with your clamps convenient and easy as well as protect them from any harsh weather conditions or exposure that can occur during transit or use outside the workshop. Their soft interiors will ensure that your investments remain safe and secure against scratches, dust, or any other form of damage during travel or transport .

Cleaning and Maintenance Tips For Adjustable Clamps For Woodworking

It is essential that you clean and lubricate the adjustable clamps for woodworking on a regular basis to ensure they work correctly. Even if your clamps have not been used in some time, any dust or dirt should be removed to reduce corrosion and wear. To do this, take a brush or toothbrush and use it to scrub away all visible dirt and dust.

Once your clamps are free of dirt, lubricate them with a light mineral oil to prevent them from rusting or seizing up during use. Use very little oil as too much can actually create complications like oil pooling or dripping off the pieces when being stored. Be sure to get in between all of the metal parts while rubbing with your finger pad to ensure coverage.

When not in use, always store your clamps indoors in a dry room temperature environment, away from direct sunlight or other sources of heat. Do not get overeager when tightening the screws as too much pressure can cause the parts to become damaged over time. If you notice any issues with your clamps at any time, take them apart and make sure all components are properly put together before using again – improper assembly can cause more damage than good!

Tips And Tricks For Working With Adjustable Clamps For Woodworking

1. Clamp Length Matters: It’s important to choose a clamp with the right length for your particular project, as the right amount of tension is often needed, depending on the size and type of wood you are working with.

2. Don’t Over Tighten Your Clamps: When using adjustable clamps to hold two pieces of wood together, be sure not to over tighten them. Too much tightening can cause cracking and splitting in the wood; instead, aim to achieve snug pressure without causing any damage.

3. Check Joints For Movement Before Releasing Clamps: Before you release your clamps from a woodworking joint, carefully inspect it for movement. If there is a gap or any sign of movement at all, then you will need to re-adjust the clamps again until everything stays in place after the clamps are released.

4. Anchor Your Workpieces To A Tabletop First: This prevents movement for items that may be too tall for clamps, such as large furniture pieces. Anchoring your workpiece also eliminates the need for additional pre-clamping and makes quick adjustment much easier and faster to perform during glue up or fine tuning operations later on down the line

5. Securely Place Clamps On Their Standoffs: When adjusting clamps with standoffs, make sure they securely stand off before placing screwdriver tips underneath so they don’t momentarily slip out of position when adding torque or pressure to tighten or loosen them manually.

Troubleshooting Common Issues For Adjustable Clamps For Woodworking

Adjustable clamps for woodworking are great tools for both seasoned and novice carpenters, but they can still run into issues. Below are common problems with adjustable clamps along with explanations of the possible causes and solutions.

One issue that may arise is that the screw adjuster on the clamp is not operating properly. This could be due to dirt or debris lodged between the threads of the screw, making it difficult to turn. To resolve this problem, remove the stuck particle using a pin or small brush before trying to use the clamp again.

Another potential problem is when screws on an adjustable clamp continually come loose during use. If this happens it may be due to a bad fit in the thread of the clamp or poor quality screws being used. The solution here is to make sure that you’re using high quality screws which fit correctly and closely into their respective holes in order to ensure that they stay secure during use.

If your clamps are not producing strong enough pressure to hold pieces firmly together, check to make sure that they are tightened correctly by fully turning them clockwise all the way down until they can’t turn anymore. Also make sure that both ends of each clamp are equal in size so that pressure is equally distributed when tightening them down.

Conclusion

Adjustable clamps are an essential piece of machinery for any woodworker. These clamps allow users to secure pieces of wood quickly and securely while still allowing them to adjust the tightness and tension when needed. Adjustable clamps can be used with a variety of different sizes and shapes of wood, making them adaptable whatever projects you may have planned. They also provide extra stability to ensure that joints remain secure through the entirety of a project’s duration. To ensure your work goes smoothly, it is important to use adjustable clamps correctly. A quick reference guide for users is included here:

1. Make sure that the clamps fit at least half an inch into the joint or corner you are trying to secure

2. Use a variety of sizes for each clamp depending on the size of your project piece

3. Secure each end of the clamp firmly so it fits snugly around both parts

4. Once tightened, slightly rotate the clamp until there is no play in either side before tightening it further

5. Adjust tightness as necessary while working on your project

In conclusion, adjustable clamps are a must-have tool for any serious woodworker, as they offer easy control over how tight joints should be and provide extra stability for any project that requires 2 or more pieces of wood joined together. Following the quick reference guide above will help ensure that each part remains secure throughout the crafting process

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.