When it comes to woodworking, having the right tools and equipment can make all the difference in the outcome of your projects. One essential tool that often gets overlooked is the woodworking vise. Whether you’re a beginner or an experienced woodworker, a woodworking vise is a valuable addition to your workshop. In this article, we will explore the purpose and benefits of a woodworking vise and why it should be considered an essential tool for any woodworking project.

A woodworking vise is a device designed to hold workpieces securely in place during various woodworking tasks. It provides stability, allowing you to perform precise cuts, shape materials accurately, and drill with confidence. With its strong grip and firm hold, a woodworking vise ensures that your workpiece doesn’t move or shift while you’re working on it. This not only improves precision but also enhances safety by reducing the risk of accidents involving power tools or sharp instruments.

The convenience offered by a woodworking vise cannot be overstated. Instead of struggling to find ways to secure your workpiece using clamps or other makeshift methods, a vise provides a reliable solution that allows you to focus solely on your craftsmanship. Whether you’re carving intricate details, joining pieces together with precision, or building furniture from scratch, a good-quality woodworking vise makes these tasks easier and more efficient.

In the following sections of this article, we will delve deeper into the topic of woodworking vises. We will explore the different types available in the market and their specific functions. We will also discuss how investing in a quality vise can enhance both precision and safety in your woodworking projects. Furthermore, we will provide tips on choosing the right vise for your needs as well as guidance on installing and maintaining it properly.

The Versatility of Woodworking Vises

Woodworking vises come in a variety of types and each type offers unique functions that cater to different woodworking needs. Understanding the different types of vises available in the market will enable woodworkers to select the one that best suits their specific requirements. Here are some common types of woodworking vises:

- Bench Vises: Bench vises are one of the most commonly used vises in woodworking. They are mounted on the workbench and provide a stable and secure grip for holding workpieces. Bench vises typically have jaws that can be adjusted to accommodate various sizes of workpieces, making them versatile for a wide range of projects.

- Shoulder Vises: Shoulder vises are specialized vises designed specifically for holding long boards or panels securely in place. They feature a larger opening between the jaws, allowing for better accessibility when working with longer pieces. Shoulder vises are commonly used in tasks such as jointing, planing, and panel assembly.

- Tail Vises: Tail vises are typically installed at the end or side of a workbench and are primarily used for clamping large or irregularly shaped workpieces securely. They usually have an adjustable sliding mechanism that allows woodworkers to position their workpiece at a convenient height and angle for comfortable and efficient woodworking.

Each type of vise has its own unique features and advantages. Deciding on which type to invest in depends on factors such as the specific tasks you’ll be performing, the size of your workspace, and personal preferences. It’s important to carefully evaluate these factors before making a decision.

Benefits of Using Different Types of Woodworking Vises

- Improved stability: Woodworking vises offer enhanced stability by firmly securing workpieces, ensuring accurate cutting, shaping, and drilling.

- Increased efficiency: With a woodworking vise, woodworkers can have both hands free to manipulate tools or focus on intricate detail work without worrying about securing the workpiece.

- Safety: Using a vise greatly reduces the risk of injury when working with power tools or sharp instruments, as it holds the workpiece securely in place.

- Versatility: Different types of vises are designed for specific woodworking tasks, allowing woodworkers to perform a wide range of projects with ease.

- Precision: A woodworking vise provides stability and eliminates movement, enabling precise measurements and clean cuts.

Investing in a quality woodworking vise is essential for any woodworker looking to enhance their precision, efficiency, and safety while working on various projects. By understanding the different types of vises available and their functions, woodworkers can make an informed decision that best suits their needs and preferences. Whether it’s a bench vise, shoulder vise, or tail vise, having a reliable woodworking vise in your workshop is a valuable asset that will greatly improve your woodworking experience.

Enhancing Precision and Safety

Woodworking is an art that requires precision and attention to detail. Whether you are cutting, shaping, or drilling, accuracy is key for a successful project. This is where a woodworking vise comes in. Investing in a high-quality woodworking vise not only enhances precision but also ensures your safety during the woodworking process.

Precision in Woodworking

One of the biggest advantages of using a woodworking vise is the ability to hold workpieces securely in place. This allows you to make accurate and precise cuts, shapes, and holes without worrying about movement or slippage. A vise acts as a third hand, firmly gripping the workpiece from different angles and positions. It eliminates any unnecessary movement that could compromise the quality of your work.

Additionally, a woodworking vise provides stability while performing intricate tasks such as carving or joinery. These techniques require steady hands and precise movements, which can be challenging without the support of a vise. By securely holding the workpiece, it allows you to focus on executing your desired design with confidence.

Ensuring Safety in Woodworking

Safety should always be a top priority when working with power tools or sharp instruments. An unstable workpiece can easily cause accidents and injuries. However, with a woodworking vise, you can significantly reduce these risks.

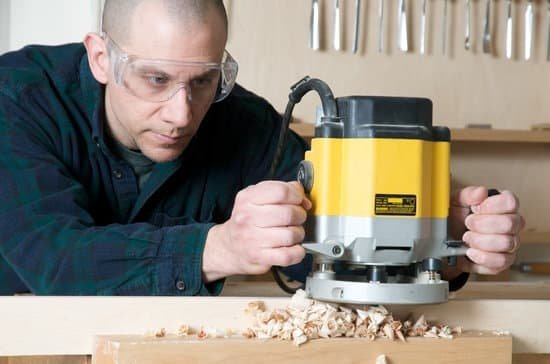

A vise holds the workpiece firmly in place, preventing any unexpected movements or slips that could lead to accidents. You can confidently use power tools like saws or routers without worrying about losing control of the workpiece. Furthermore, by keeping your hands away from the cutting action, a vise adds an extra layer of protection against potential injuries.

DIY Woodworking Projects Made Easier

Joinery: Enhancing Accuracy and Stability

A woodworking vise is an essential tool for joinery projects, where precision and stability are critical. Whether you’re creating dovetail joints, mortise and tenon joints, or box joints, a vise will securely hold your workpieces in place, allowing you to make accurate cuts and ensure tight-fitting joints. The vise’s strong grip prevents any movement or shifting of the wood during cutting or chiseling, resulting in cleaner and more professional-looking joinery.

Experienced woodworkers often rely on woodworking vises to improve their efficiency during joinery work. By holding the workpiece at a comfortable height and angle, a vise enables them to comfortably operate their tools while maintaining complete control over the material. This level of control not only improves accuracy but also minimizes the chances of injuries caused by slipping tools.

Carving: Maximizing Control and Safety

When it comes to carving intricate designs or sculpting wood, having a woodworking vise is invaluable. Carving often requires applying significant force to shape the material precisely, which can be challenging without proper support. A vise allows you to firmly secure the piece you’re working on, providing stability and minimizing vibrations that could affect your carving lines.

Moreover, using a woodworking vise for carving enhances safety by keeping your hands away from sharp tools. With the workpiece secured in place, you can focus solely on your technique without worrying about accidental slips or cuts. The vise acts as an extra pair of hands that securely holds the wood while you navigate delicate curves and edges with confidence.

Furniture Making: Streamlining Assembly Processes

Woodworking vises are particularly useful for furniture makers during assembly processes. When joining multiple pieces together – such as table legs or cabinet panels – it can be challenging to keep everything aligned while applying clamping pressure. This is where a vise comes in handy, ensuring that all parts remain properly positioned and aligned until the glue dries or the fasteners are securely tightened.

Furthermore, a woodworking vise allows for hands-free work during assembly. Assembling furniture often involves juggling multiple pieces and tools simultaneously. By using a vise, you can free up your hands to hold and manipulate other components while the vise holds the main structure in place. This makes the assembly process smoother and more efficient, saving time and effort.

Overall, whether you’re tackling joinery projects, intricate carvings, or furniture making, a woodworking vise is an indispensable tool for enhancing accuracy, control, and safety. Its ability to securely hold workpieces in place allows you to focus on fine details without worrying about movement or slippage. Invest in a high-quality woodworking vise and elevate your DIY woodworking projects to professional-level craftsmanship.

Factors to Consider When Choosing a Woodworking Vise

When choosing a woodworking vise, there are several factors that you should take into consideration to ensure that you select the most suitable option for your specific needs and preferences. These factors can greatly impact the functionality and effectiveness of your vise, so it’s important to weigh them carefully before making a purchase.

- Size: One of the first considerations when choosing a woodworking vise is its size. The size of the vise refers to both the overall dimensions and the jaw width. A larger vise may offer more working space and the ability to hold larger workpieces, but it can also be more cumbersome and take up valuable space on your workbench.

- Material: The material of the vise is another important factor to consider. Woodworking vises are commonly made from cast iron or steel. Cast iron vises are typically heavier and more durable, but they can also be more expensive. Steel vises, on the other hand, tend to be lighter and more affordable, but they may not have the same level of durability as cast iron vises.

- Jaw Width: The width of the jaws on a woodworking vise will determine how securely it can grip different sizes and shapes of workpieces. A wider jaw width provides more surface area for clamping, allowing you to hold larger or irregularly shaped pieces with greater stability. It’s important to choose a jaw width that suits the type of projects you regularly work on.

- Mounting Method: Consider how you plan to mount your woodworking vise. There are various mounting methods available, including bench-mounted vises that attach directly to your workbench, as well as options that can be mounted underneath or on top of your work surface. The mounting method will depend on your specific workspace setup and personal preference.

- Price: Finally, consider your budget when choosing a woodworking vise. Prices for vises can vary widely depending on their features, materials, and brand.

It’s important to set a budget and look for a vise that offers the features you need within your price range. Remember that investing in a quality vise can greatly enhance your woodworking experience and produce better results, so it may be worth allocating a larger portion of your budget towards this tool.

By considering these factors when choosing a woodworking vise, you can ensure that you select the right tool that will meet your needs and help you achieve professional-level results in your woodworking projects. It’s important to take the time to research different options, read reviews from other woodworkers, and consider how each factor aligns with your specific requirements.

Step-by-Step Guide

Installing and maintaining a woodworking vise properly is essential for optimal performance and longevity. This step-by-step guide will walk you through the process of installing your woodworking vise on your workbench or tabletop, as well as provide useful tips on how to maintain and clean it.

- Selecting the Right Location: Before installing your woodworking vise, choose a suitable location on your workbench or tabletop. Consider factors such as accessibility, stability, and the ability to clamp various sizes of workpieces securely. Ensure that the vise is positioned at a comfortable working height for you.

- Marking and Preparing the Mounting Holes: Once you have chosen the installation location, carefully mark the mounting holes according to the instructions provided with your vise. Use a center punch to make indents at each marked hole to prevent drill bits from slipping during drilling.

- Drilling Pilot Holes: Using an appropriate-sized drill bit, carefully drill pilot holes at each marked indent. Take care to align the drill perpendicular to the surface to ensure a straight and secure installation.

- Attaching the Vise: Position your woodworking vise over the drilled pilot holes and insert screws or bolts provided with your vise into each hole. Tighten them securely using a screwdriver or wrench, ensuring that they are flush with the mounting surface.

- Checking for Stability: After attaching the vise, check its stability by applying pressure in different directions. It should not wobble or move excessively when secured properly.

Maintaining Your Woodworking Vise:

- Keeping it Clean: Regularly clean your woodworking vise by removing any dust, debris, or sawdust that may accumulate in the jaws or other moving parts. You can use compressed air or a brush to dislodge stubborn particles.

- Lubrication: Apply lubricating oil or grease to any moving parts of your vise, such as threaded rods, pivot points, and slide mechanisms. This will ensure smooth and effortless operation.

- Inspecting for Wear: Regularly inspect your vise for signs of wear or damage, such as worn-out jaws or loose parts. Replace any worn-out or damaged components promptly to maintain the vise’s effectiveness.

By following this step-by-step guide and maintaining your woodworking vise regularly, you can ensure its proper functioning and longevity. A well-installed and well-maintained vise will provide you with a reliable tool that holds your workpieces securely and allows you to work with precision and safety.

| Installation Steps | Maintenance Tips |

|---|---|

| Selecting the Right Location | Keeping it Clean |

| Marking and Preparing the Mounting Holes | Lubrication |

| Drilling Pilot Holes | Inspecting for Wear |

| Attaching the Vise |

How to Get the Most Out of Your Woodworking Vise

Woodworking vises are essential tools that provide stability and security when working on woodworking projects. However, there are various tips, tricks, and techniques that can help woodworkers maximize the functionality and efficiency of their vise. By utilizing these strategies, individuals can enhance their woodworking experience and achieve professional-level results.

One important tip is to properly position the workpiece in the vise. Woodworkers should ensure that the piece is securely clamped in place and that it is centered and parallel to the vise jaws. This will help prevent any unwanted movement or shifting during the woodworking process.

Another useful technique is to utilize additional accessories with the woodworking vise. For example, using soft jaw covers can protect delicate or finished surfaces from being marred or damaged by the vise jaws. Additionally, using holdfasts or bench dogs can provide additional support and stability when working on larger workpieces.

Furthermore, a creative application of a woodworking vise is utilizing it for tasks beyond simply holding workpieces in place. For instance, it can be used as a makeshift third hand by attaching a block of wood between the jaws and using it as a support for holding tools or helping with assembly tasks. This allows woodworkers to have both hands free while still maintaining stability and control over their work.

| Tip/Technique | Description |

|---|---|

| Properly position workpiece | Center and parallel alignment prevents movement during woodworking. |

| Use additional accessories | Soft jaw covers protect delicate surfaces, while holdfasts and bench dogs provide additional support. |

| Creative applications | Utilize the vise as a makeshift third hand for holding tools or providing support during assembly tasks. |

Alternatives to Traditional Woodworking Vises

Woodworking vises are an essential tool for many woodworkers, providing a secure and stable means of holding workpieces in place. However, there are alternative clamping solutions and techniques that can be used in combination with or as alternatives to traditional woodworking vises.

One alternative to traditional woodworking vises is the use of bench dogs and holdfasts. Bench dogs are pegs that fit into holes drilled into the workbench’s surface, allowing for a variety of clamping options. Holdfasts, on the other hand, use leverage to secure workpieces against the bench surface. Both bench dogs and holdfasts provide flexibility in terms of positioning and can be easily adjusted or removed as needed.

Another innovative solution is the use of clamping jigs and fixtures. These tools are designed to hold specific workpieces or perform specific tasks. For example, there are specialized jigs for holding dowels, ensuring precise drilling angles and depths. There are also adjustable guides and fences that help maintain consistent cuts during sawing or routing operations.

In addition to these alternatives, some woodworkers utilize magnetic clamps or adhesive tapes to secure their workpieces. Magnetic clamps offer quick and convenient clamping options for smaller projects or when precision is not critical. Adhesive tapes, such as double-sided tape or carpet tape, can be used to temporarily attach small or irregularly shaped workpieces to a stable surface.

When considering these alternatives to traditional woodworking vises, it’s important to weigh their pros and cons against your specific needs and preferences. While they may offer more flexibility in certain situations, they may not provide the same level of stability as a dedicated vise. It may also be necessary to invest in additional tools or accessories to fully utilize these alternative clamping methods.

Conclusion

In conclusion, a woodworking vise is an indispensable tool for any woodworker, whether they are a beginner or experienced craftsman. Throughout this article, we have explored the purpose and benefits of a woodworking vise, as well as its versatility and various applications. We have also discussed factors to consider when choosing a vise and provided step-by-step instructions on installation and maintenance.

One of the key takeaways from this discussion is the enhanced precision and safety that a woodworking vise offers. Woodworking requires accuracy in cutting, shaping, and drilling, and a vise ensures that workpieces are held securely in place during these processes. This not only leads to more precise results but also reduces the risk of accidents by keeping hands clear of sharp tools or power machinery.

Additionally, we have seen how a woodworking vise simplifies complex projects by providing stability and support. Whether it is joinery work, carving intricate designs, or constructing furniture pieces, a vise makes these tasks easier by firmly holding the material in place. The testimonials from experienced woodworkers only further emphasize the functionality and efficiency offered by a quality vise.

Therefore, investing in a woodworking vise is strongly recommended for anyone passionate about woodworking. By doing so, you can enhance your woodworking experiences and achieve professional-level results. Take the time to consider your specific needs and preferences when choosing a vise; finding one that suits your requirements will undoubtedly elevate your craftsmanship to the next level.

Frequently Asked Questions

What do you use a woodworking vise for?

A woodworking vise is a tool primarily used to firmly hold workpieces in place during woodworking tasks. It is typically attached to a workbench and consists of two jaws, one movable and one fixed, that can be tightened together to secure the material being worked on.

The vise provides stability and prevents the workpiece from moving or shifting while the woodworker performs various operations such as sawing, drilling, planing, or carving. By securely holding the wood in place, the vise allows for greater precision and control during these tasks.

What can I use if I don’t have a vise?

If you don’t have access to a woodworking vise, there are alternative options you can use to secure your workpiece while working on it. One commonly used substitute is using clamps. Clamps can be attached to either side of a work surface or even improvised by using objects like C-clamps or quick-release bar clamps.

These clamps provide sufficient grip and stability to keep the workpiece steady during most woodworking tasks. Additionally, you may also consider using bench dogs, which are small pegs that fit into holes on your workbench and help support and stabilize the piece you’re working on.

Why do you need a vise?

A vise is an essential tool in woodworking due to its ability to securely hold materials in place while allowing easy access for various operations. It plays a vital role in ensuring safety by preventing accidental slips or movements of the workpiece, which could potentially lead to injuries or mistakes.

Furthermore, a vise offers improved accuracy and precision when cutting or shaping wood since it prevents any unwanted shifts during these processes. The stable platform provided by a vise allows woodworkers to focus on their craftsmanship without worrying about holding the material firmly in position throughout their projects, ultimately enhancing efficiency and quality of their workmanship.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.