Introduction

Woodworking is the art of creating useful objects from a variety of materials, especially wood. It requires skill and precision, as well as an understanding of the material and its properties. Handmade woodworking benches are often worth it because they are built to last and can provide a unique design that is exclusive to the individual craftsman. A good quality handmade bench will also be highly functional and versatile, providing both extra work space and storage options for tools. Additionally, hand crafted furniture has a unique beauty that comes from being made with careful attention to each detail, resulting in a piece that is both attractive and durable.

Understand Woodworking and its Different Styles

Woodworking is an art form that involves the use of materials such as wood and its derivatives to create functional or aesthetic items. Woodworking techniques have been developed and refined through different generations, leading to a wide selection of styles. Examples of traditional styles include Scandinavian craftsman work, Arts & Crafts furniture, French provincial furniture and Shaker designs. Contemporary styles may incorporate modern materials such as metals, plastic, composites and other high-tech components like lasers. Each style features unique characteristics that can be defined by way of the shapes, lines and accents used in each piece of furniture or craft item. For example, Scandinavian work typically features elegant curves while Arts & Crafts relies heavily on clean lines and geometric patterns. Furthermore, the type of wood used in the construction can further enhance the character of each style. When considering building a handmade woodworking bench it’s important to consider these characteristics when selecting the design solutions for your project

What Materials Make a Quality Woodworking Bench

A quality woodworking bench needs to be constructed from high-quality materials. Ideally, it should be made of hardwood such as oak or ash and should feature steel hardware such as dowels, bolts, clamps, and screws. The top of the bench should be made from laminate materials like Formica or masonite to provide a smooth surface that won’t easily warp when stressed by projects. Additionally, the legs and base should have solid joinery to ensure stability during use. Depending on the type of projects that will be performed on the bench, a vice can also be incorporated into its design for extra efficiency. Lastly, when possible it’s recommended to attach plywood siding along the edge of the bench as a way to protect against any splintering or chipping while working on projects.

Types of Woodworking Benches & Their Unique Features

There are many different types of woodworking benches and each one has its own unique features that make it the perfect choice for a variety of woodworking tasks. For example, a tailbench is designed to be used when crosscutting and can usually hold up to two pieces of stock at once. It is usually longer than other benches and has a wide top surface ideal for supporting long pieces of wood. A choppbench is designed with a stop block on one side, allowing accurate cuts while providing extra support on the other side. This makes it great for people who need to trim down larger pieces of stock. A shoulder bench is typically slightly taller than other benches and comes with adjustable blades that allow for precision cutting along edges. Finally, a sawbench is built specifically for using saws and features an open base design with open sides that provide support for long pieces of cut stock. Each one of these unique features will help make sure you have the right bench for whatever job you need to accomplish!

Advantages of Handmade Woodworking Benches

A handmade woodworking bench offers a wide range of advantages over store-bought commercial benches. One of the most significant benefits is the flexibility and versatility it offers due to its custom design. Unlike commercial benches, which usually come with limited features or a set design, a handmade woodworking bench can be designed to fit your specific needs. This means you can customize your own space to include attachments such as vises, saws, chisels and more to better suit your projects or hobbies.

Another advantage of having a handmade woodworking bench is that you can use high-quality materials that will last longer while maintaining stability under heavy loads. For instance, solid hardwood may not be affordable when opting for commercial benches but are popular options when making your own handmade bench. These materials provide unmatched strength and durability to handle regular use and the toughest projects with ease.

In addition to customization and high-quality materials, another great benefit of having a handmade woodworking bench is that can it become an integral part of your workstation setup very quickly. With all the necessary tools easily accessible while working on your project without having to constantly hunt down other supplies further saves you time and makes it easier to focus on the task at hand – perfect for hobbyists and craftsmen alike; fine workmanship from beginning till the end!

Building Handmade Woodworking Benches

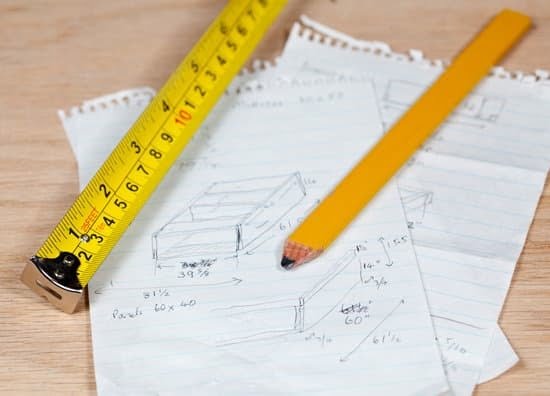

The process of building a handmade woodworking bench starts with gathering the necessary tools and materials for the job. Begin by measuring and cutting the right size lumber to build the frame of the bench. You’ll need a miter saw, drill, jointer and circular saw if you don’t have access to a table saw to cut your pieces accurately. Once the frame is assembled, you will attach 4 inch-long legs to each corner using bolts, screws or dowels.

Next, attach a plywood top to provide stability and add upholstry foam or other padding material on top before covering it with batting and fabric. Finally, finish off the bench with varnish or sealer for long-term protection.

You can also opt for building drawers in your woodworking bench for added storage capacity by pre-drilling holes for mounting drawer slides that slide into designated slots in each side of the frame. If your project involves detailed work such as carving or shaping wood pieces, a vise can be mounted onto either side of the bench to secure both large and small components during sanding, planing or filing operations. Finally, depending on preference, staining can be done on all parts of the handmade woodworking bench before adding protective coats such as lacquer or catalyzed varnish to make it waterproof and resistant against damage from spills or moisture from air humidity changes.

Showcase of Handmade Woodworking Benches Ideas

Handmade woodworking benches allow those with woodworking talents to put their craftsmanship on full display. Crafting a quality bench requires skill, talent, and precision. Handy woodworkers can fashion highly sought-after and unique pieces that are both functional and decorative. Using a wide range of materials such as solid woods, ornate carvings, iron accents and colorful stains, wooden benches can be made from any type of design and let the craftsman express their own personality. Skillful construction also allows for custom sizing so each bench is uniquely fitted to its intended use. Whether a dining bench, garden seat or entryway storage piece, these inventive carpentry projects can provide an attractive accent to the home or yard.

Finishing Touches

The finishing touches on a handmade woodworking bench can really tie the entire look together and make it look truly exceptional. While there are many different techniques that can be used, here are some expert tips to help bring your bench up to a professional level:

1. Take care when staining and sealing your wood. This will protect it from moisture damage, lend it an attractive colour, and keep it looking great for years to come. Use a damp cloth to apply an even coat of stain and sealer over the entire surface of the bench. Allow at least 24 hours for this coat to dry before sanding, so ensure you plan ahead!

2. Start sanding with a medium-grit sandpaper, and then transition all the way up to a fine grit for added smoothness and shine. Work in circles in order to create an evenly-sanded surface across the entire outer layer of your work of art.

3. After you’ve finished sanding, apply polyurethane for an advanced level of protection against wear-and-tear or water damage. Apply three separate coats with a brush – wait 10 minutes between each coat – until you achieve a flawless finish that reveals no streaks or bubbles beneath it.

4. For extra finesse, consider adding metal accents such as cast iron handles or hinges; these details can really make the bench stand out while also making it easier to use day-to-day too! Of course don’t forget staples, nails, screws and other small hardware items which will give your bench’s wooden construction extra stability and longevity – not to mention soldify your carpentry skills as well!

5. Woodworkers know that beeswax is essential for any handmade project; this natural wax really brings out the grain in wood pieces and adds unmatched polish to their surfaces; its outstanding protective qualities won’t hurt either! Simply rub over your sanded surface lightly with a soft cloth or brush containing beeswax – let sit overnight before buffing off the excess wax in vertical strokes!

Maintenance and Storage of Your Handcrafted Woodworking Bench

Once you have your handmade woodworking bench crafted from quality materials, you will need to properly maintain it in order to make sure it lasts for many years. A few simple tips can make all the difference when caring for your bench:

1. Keep a cover over the bench when not in use. This will help prevent moisture and dust from settling into the wood and causing wear and tear on its surface.

2. Whenever possible, keep your tools on a separate rack or shelf so that they don’t weigh down on the bench itself and cause damage over time.

3. Make sure to regularly clean up any debris that has gathered on the workbench before storing it away. This will help lessen the chances of getting dirt or dust inside while stored away, which can be hard to remove once embedded in the wood grain.

4. Before storage, apply a sealant or wax to the wood to protect it against humidity and other challenging elements associated with long-term exposure to air particles.

5. Finally, be sure to store your workbench in an area where temperature/humidity levels are controlled; both too high or too low of humidity can compromise wood’s integrity over time, causing warping or cracking as well as inviting unwanted critters into your workspace!

Conclusion

A handmade woodworking bench is a worthwhile investment for anyone who wants to enjoy the rewards of crafting beautiful pieces of furniture. Not only will it provide a stable and safe base for any project, but it will also help keep you in good shape, as it offers more support than regular benches. The quality craftsmanship that goes into creating a handmade woodworking bench ensures that it will last years without needing repairs or maintenance. Furthermore, because of the hardwood and metal parts used in its construction, this type of bench is extremely durable and able to withstand the normal wear and tear expected with woodworking projects.

The purchase of a handmade woodworking bench can easily be considered an investment towards one’s future, since it will always remain useful no matter how much time goes by. It increases the functionality of any workshop while offering a beauty that many types of store-bought benches simply cannot match. A well-made bench also serves as an anchor for all other pieces in the space; from working on small detailed tasks like precise tooling work to putting together larger complex structures through joinery techniques such as dovetails or mortise and tenon joints – all these activities are greatly simplified when done on top of a quality handmade woodworking bench. Additionally, by having such a well-built piece of furniture at home or in your shop allows one to demonstrate his skills to family members or customers alike – serving both as a great source of pride and increased productivity.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.