Building your own woodworking shop is a dream come true for many woodworking enthusiasts. It is not only a space where you can let your creativity fly and bring your woodworking projects to life, but also a sanctuary that offers numerous practical benefits. Whether you are a hobbyist or a professional, having a dedicated woodworking shop provides you with an organized and productive environment where you can work on your craft without any interruptions or limitations.

One of the key benefits of having a woodworking shop is the freedom it grants you to pursue your passion. With a dedicated space solely for woodworking, you can easily dive into projects whenever inspiration strikes, without worrying about setting up in temporary areas or dealing with space constraints. A well-designed and organized workshop also allows for better workflow efficiency, as tools are readily available and workbenches have ample workspace to accommodate various projects.

Furthermore, having your own woodworking shop enables you to expand your skills and take on more ambitious projects. With easy access to all necessary tools and equipment, you can confidently tackle complex techniques and experiment with different materials. This expanded opportunity to grow as a woodworker ultimately leads to greater satisfaction with the quality of your work and opens doors for potential opportunities such as selling handmade crafts or taking on custom orders.

In this article, we will guide you through the process of building your very own woodworking shop step by step. From selecting the right location and designing an efficient layout to considering electrical setup and safety measures, we will cover everything you need to create the perfect workspace. So grab your blueprint notebook, put on your tool belt, and let’s begin this exciting journey towards building your dream woodworking shop.

Selecting the right location

Selecting the right location for your woodworking shop is crucial for creating a successful and efficient workspace. Here are some important factors to consider when choosing a suitable space:

Space Requirements

First and foremost, assess how much space you need for your woodworking shop. Consider the size of the projects you typically work on and ensure that your chosen location can accommodate them comfortably. Take into account both the square footage of the shop area itself as well as any additional space needed for material storage, tool organization, and workbenches.

Accessibility

The accessibility of your woodworking shop is an important factor to consider. Ideally, you want your shop to be easily accessible from your home or other areas where you spend most of your time. This will save you valuable commuting time and make it convenient to work on projects whenever inspiration strikes.

Considerations such as parking availability, loading and unloading requirements, and proximity to suppliers should also be taken into account. It can be beneficial to have a separate entrance or direct access to the outside so that wood chips, sawdust, and finished pieces can easily be transported in and out without causing disturbances inside the main building.

Noise Considerations

Woodworking can generate a significant amount of noise, especially when using power tools like table saws or planers. When selecting a location for your woodworking shop, consider its proximity to neighboring properties or living spaces where excessive noise may cause disturbances.

It may be wise to choose a location within a detached building where soundproofing measures can be taken if necessary. Alternatively, if noise control is not feasible in your chosen location, communicate with neighbors beforehand and consider implementing scheduling strategies around quieter hours to minimize disruptions.

By carefully considering these factors – space requirements, accessibility, and noise considerations – you will be able to select a suitable location for your woodworking shop that meets both practical needs and ensures harmonious relationships with your surroundings.

Designing the layout

Designing the layout of your woodworking shop is crucial for creating an efficient and functional workspace. A well-designed layout not only maximizes the use of space but also enhances productivity and workflow. Here are some tips and techniques to help you plan and create an optimal layout for your woodworking shop.

Firstly, it’s important to consider the size and shape of your woodworking shop space. Take accurate measurements of the area to determine what type and size of equipment can fit comfortably. Consider any existing obstructions such as windows, pillars, or electrical outlets that may affect the placement of machines and workstations.

Next, think about the flow of work in your shop. The most common layout pattern is a “workflow triangle” which consists of three main areas: the cutting area, assembly area, and finishing area. This triangular layout minimizes unnecessary movement between tasks, saving time and reducing fatigue.

In terms of equipment placement, prioritize placing frequently used tools closer to your workbench or main workstation for easy access. Organize your tools based on their function or size, keeping them within arm’s reach for increased efficiency.

Creating dedicated zones within your woodworking shop can also improve organization and functionality. For example, designate a separate area for wood storage to keep it easily accessible yet out of the way during projects. Set up a separate sharpening station with appropriate ventilation to maintain sharp tools. Creating designated areas helps streamline processes by keeping things organized.

Overall, designing the layout of your woodworking shop requires careful consideration of space limitations, workflow patterns, tool accessibility, and organization strategies. By planning an efficient layout that caters to your specific needs and preferences, you can transform your woodworking shop into a productive workspace that enhances both creativity and craftsmanship.

| Tips | Techniques |

|---|---|

| Consider size & shape of space | Measure accurately |

| Plan for workflow triangle | Optimize movement between areas |

| Place frequently used tools close to workbench | Easy access and efficiency |

| Create dedicated zones for specific activities | Improved organization and functionality |

Essential tools and equipment

When building a woodworking shop, one of the most important considerations is having the right tools and equipment. Without them, it can be challenging to complete projects efficiently and achieve the desired results. In this section, we will provide a comprehensive guide to the must-have tools and equipment to equip your woodworking shop for success.

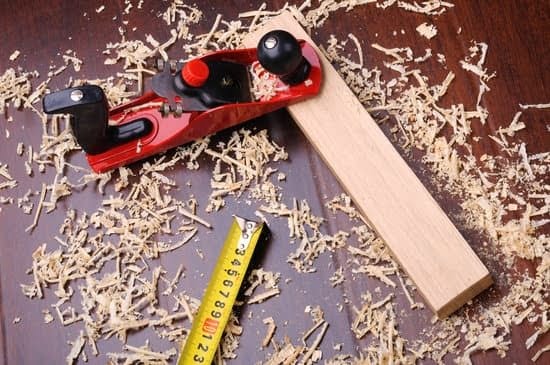

First and foremost, every woodworking shop should have a set of essential hand tools. These include items such as chisels, hand saws, planes, screwdrivers, and clamps. These tools are crucial for tasks that require precision and finesse, allowing you to shape and assemble wood with ease.

In addition to hand tools, power tools are also essential in a woodworking shop. Some key power tools include a table saw, miter saw, band saw, router, drill press, and planer. These power tools enable you to cut materials accurately, shape edges and surfaces, create joinery, bore holes for screws or dowels, and flatten rough lumber.

Alongside the basic hand and power tools, there are several other equipment items that can greatly enhance your woodworking shop’s functionality. These include a workbench with vise grips for stability when working on projects, various clamps for securing pieces during assembly or while gluing joints together, a dust collection system to minimize airborne particles and keep your workspace clean, as well as safety equipment like goggles ear protection.

By equipping your woodworking shop with these essential tools and equipment items mentioned above (and many more that may suit your specific needs), you’ll be well-prepared to tackle any project that comes your way. Remember that investing in quality tools will not only make your work more enjoyable but also ensure accurate results and longevity of your equipment. So take the time to research trusted brands and read reviews before making purchases.

Creating a dust-free environment

Woodworking can be a messy task, with sawdust and other debris filling the air and settling on surfaces. However, creating a dust-free environment in your woodworking shop is essential for maintaining a clean and healthy working space. Not only does it contribute to better air quality, but it also improves overall productivity by reducing cleanup time and preventing damage to tools and equipment.

There are several effective strategies you can employ to minimize dust in your woodworking shop. One of the most important steps is to invest in a high-quality dust collection system. This system will capture the majority of the dust particles produced during cutting, sanding, and shaping wood.

It typically consists of a collection hood attached to each machine that generates dust, connected by ductwork to a central dust collector or vacuum system. Make sure to choose a system that is appropriate for the size of your shop and consider factors such as airflow capacity and filtration efficiency.

Another important strategy is to implement proper housekeeping practices in your woodworking shop. Regularly sweep or vacuum the floor to remove loose debris, paying extra attention to corners and hard-to-reach areas where dust tends to accumulate. You should also wipe down surfaces such as workbenches, shelves, and tools regularly with damp cloths or microfiber towels to prevent dust from settling.

Lastly, consider investing in air filtration systems or air purifiers to further improve air quality in your woodworking shop. These systems remove airborne particles including fine dust particles that may not be captured by your dust collection system. Look for models that are specifically designed for woodworking shops and have high-efficiency particulate air (HEPA) filters.

Creating a dust-free environment in your woodworking shop may require some initial planning and investment, but the benefits are well worth it. Not only will you enjoy cleaner air and reduced cleanup time, but you will also extend the lifespan of your tools and equipment by preventing them from becoming clogged with debris. By following these effective strategies, you can ensure a clean and healthy working environment in your woodworking shop.

| Strategy | Description |

|---|---|

| Invest in a high-quality dust collection system | This system will capture the majority of the dust particles produced during woodworking tasks. |

| Implement proper housekeeping practices | Sweep or vacuum the floor regularly, wipe down surfaces, and remove dust from corners and hard-to-reach areas. |

| Invest in air filtration systems or air purifiers | These systems remove airborne particles, including fine dust particles that may not be captured by your dust collection system, improving overall air quality in your shop. |

Building workbenches and storage solutions

One of the most crucial components of a woodworking shop is a sturdy workbench. A well-built workbench provides a solid foundation for all your woodworking projects, giving you stability and support as you work with various tools and materials. Here is a step-by-step guide to help you construct your own durable workbench:

- Determine the size and height: Consider the type of projects you will be working on and the available space in your shop. Measure the ideal dimensions for your workbench, ensuring that it suits your height to provide maximum comfort while working.

- Choose the right materials: Select high-quality lumber that can withstand heavy-duty use. Popular options include hardwood such as maple or birch for the top surface, and sturdy dimensional lumber like 2x4s for the frame.

- Assemble the frame: Cut the lumber according to your desired dimensions for both the legs and support beams. Use wood screws or strong joinery techniques like mortise and tenon or dovetail joints to secure everything together.

- Build the top surface: Cut your hardwood boards to size, ensuring they align perfectly to create a smooth workspace. Glue them together side by side, then sand them until they are flush and seamless.

- Attach the top to the frame: With assistance, flip your completed top surface onto its legs, making sure it’s centered properly. Secure it firmly using screws or bolts through pre-drilled holes, creating a stable connection between the top and frame.

In addition to workbenches, implementing effective storage solutions in your woodworking shop is vital for organization and efficiency. Here are some tips on optimizing storage space:

- Wall-mounted tool racks: Install racks or pegboards on walls to hang frequently used hand tools such as hammers, saws, chisels, and screwdrivers. This not only keeps your tools easily accessible but also saves valuable floor space.

- Modular shelving units: Utilize adjustable shelves or modular storage systems to accommodate different sizes of materials, such as lumber or plywood sheets. These versatile storage solutions allow you to customize the height and configuration according to your specific needs.

- Roll-out bins and drawers: Incorporate roll-out bins or drawers under workbenches or tables to keep smaller tools, hardware, and accessories organized. This not only maximizes storage capacity but also ensures easy access to frequently used items.

By following these step-by-step instructions for building a sturdy workbench and optimizing storage space in your woodworking shop, you can create a highly functional workspace that enhances productivity and organization. Remember to tailor the design and layout to your specific needs while considering the available space in your shop. With a well-designed work area and efficient storage solutions, you’ll be able to focus more on honing your woodworking skills and bringing your creative projects to life.

Electrical and lighting considerations

Proper Electrical Setup

When building a woodworking shop, one of the most important considerations is the electrical setup. Without a proper electrical system, it can be challenging to power all the tools and equipment needed for woodworking projects. Here are some key tips and practices for ensuring a safe and effective electrical setup in your workshop:

- Hire a professional electrician: Unless you have extensive knowledge and experience in electrical work, it is highly recommended to hire a licensed electrician to handle the installation and wiring of your woodworking shop. This ensures that all the work is done correctly and up to code.

- Calculate your power needs: Before beginning any electrical work, determine the power requirements of your tools and equipment. Make a list of all the tools you plan to operate simultaneously and calculate their combined amperage needs. This will help determine the size of your circuit breaker panel, wire gauge, and outlets needed in the shop.

- Install dedicated circuits: To prevent overloading circuits, it is crucial to have dedicated circuits for heavy-duty equipment such as table saws or planers. This means each tool should have its own individual circuit from the breaker panel directly to an outlet near where it will be used.

Adequate Lighting

In addition to proper electrical setup, adequate lighting is essential for creating a functional and safe woodworking environment. Insufficient lighting can lead to accidents or mistakes during work. Here are some tips for achieving optimal lighting in your woodworking shop:

- Natural light: If possible, take advantage of natural light by positioning windows strategically throughout your workshop or installing skylights. Natural light not only provides better visibility but also creates an inviting atmosphere.

- Overhead lighting: Install overhead LED or fluorescent lights with adjustable brightness settings to accommodate different tasks. Position them evenly throughout the space to eliminate shadows and provide consistent illumination.

- Task lighting: For specific work areas such as the workbench or lathe, consider installing task lighting fixtures that can be easily adjusted to provide direct light exactly where it is needed. This will help minimize eye strain and improve visibility for intricate tasks.

Safety Precautions

When working with electricity, safety should always be a top priority. Here are some important safety precautions to follow when setting up the electrical system in your woodworking shop:

- Grounding: Ensure that all outlets and equipment are properly grounded to prevent electrical shocks. Use three-pronged plugs and grounded outlets throughout your workshop.

- GFCI protection: Install ground fault circuit interrupters (GFCIs) in areas where water may be present, such as near sinks or wet grinders. GFCIs detect abnormal electrical current flow and quickly shut off power to prevent electric shock.

- Labeling: Clearly label each circuit breaker in your electrical panel corresponding to specific tools or equipment. This makes it easy to identify which breaker controls which area of your woodworking shop for quick shut-off during emergencies.

By taking the time to plan and implement a proper electrical setup and adequate lighting in your woodworking shop, you can create a safe and productive environment that promotes efficient work and creativity. Always consult professionals when dealing with electrical work to ensure everything is done correctly and prioritize safety at all times.

Ventilation and air filtration

The Importance of Ventilation and Air Filtration

When it comes to creating a woodworking shop, ensuring proper ventilation and air quality should be a top priority. Woodworking involves the creation of fine particles and dust that can pose health risks if inhaled regularly over time. Additionally, certain types of wood may release chemicals or allergens into the air, further emphasizing the need for effective ventilation and air filtration systems in your workspace.

Investing in a Dust Collection System

One of the most important steps you can take to maintain a healthy work environment is investing in a reliable dust collection system. This system will help capture airborne dust particles before they have a chance to settle on surfaces or enter your lungs.

When selecting a dust collection system, consider factors such as the size of your shop, the type of woodworking you plan to do, and the power requirements. Research various models and consult with professionals in order to choose one that suits your needs best.

Proper Ventilation Strategies

In addition to dust collection systems, implementing proper ventilation strategies is crucial for maintaining good air quality within your woodworking shop. The goal is to establish a constant flow of fresh air into the space while simultaneously venting out stale or contaminated air. One simple yet effective strategy is to install windows that can be opened easily when needed. This allows for cross-ventilation, which helps remove potentially harmful substances from the indoor environment.

Another key aspect of proper ventilation is controlling humidity levels within your shop. High humidity can lead to an increased risk of mold growth, which can negatively impact both your health and the longevity of your tools and equipment. Consider installing dehumidifiers or utilizing fans to manage humidity levels effectively.

Use Air Filtration Systems

Air filtration systems act as an additional line of defense against airborne particles in your woodworking shop. These systems are designed to filter and clean the air, capturing fine particles and dust that may not be captured by a dust collection system alone. Look for air filtration systems that have high-quality HEPA (High-Efficiency Particulate Air) filters, as they are known to effectively remove even the smallest particles from the air.

Safety measures and protective equipment

Safety measures and protective equipment are crucial elements to consider when building and operating a woodworking shop. Woodworking involves working with various tools and materials that can pose risks if not handled properly. By following clear guidelines, using personal protective equipment (PPE), and implementing best practices, woodworkers can maintain a secure working environment.

One of the first steps in ensuring safety in a woodworking shop is to establish clear guidelines. These guidelines should include rules regarding the safe operation of machinery, proper use of tools, handling of materials, and general safety practices. It is important to educate oneself on these guidelines and enforce them strictly within the workshop.

Personal protective equipment (PPE) is essential for protecting oneself from potential hazards in a woodworking shop. Woodworkers should always wear safety glasses or goggles to protect their eyes from flying debris or dust. Hearing protection, such as earmuffs or earplugs, should be worn when operating noisy machinery. Additionally, wearing appropriate clothing, including closed-toe shoes and fitted garments that do not hang loosely, can help prevent accidents caused by loose clothing getting caught in machinery.

Best practices for maintaining a secure working environment include keeping the workspace clean and organized. Clearing away sawdust and debris regularly helps prevent slips, trips, and falls. Tools should be properly maintained, with sharp blades and bits replaced as needed. Implementing good housekeeping practices also includes storing flammable materials properly and ensuring fire extinguishers are readily available.

Overall, prioritizing safety measures and using proper protective equipment is essential when building and operating a woodworking shop. By following clear guidelines, wearing PPE, practicing best practices for maintaining a secure workspace, woodworkers can minimize the risk of accidents or injuries while pursuing their craft. Remembering that safety should always come first will allow woodworkers to enjoy their work with peace of mind in their dedicated woodworking space.

Building a community and resources

Woodworking is an art form that requires not only skill but also inspiration. One of the best ways to enhance your woodworking skills and stay motivated is by joining woodworking communities. These communities provide a platform for woodworkers of all levels to come together, share their knowledge, learn from each other’s experiences, and find inspiration for their projects.

There are numerous benefits to joining woodworking communities. Firstly, you gain access to a wealth of knowledge and expertise. These communities consist of experienced woodworkers who are more than willing to share their tips, tricks, and techniques. Whether you’re looking for advice on joinery techniques or recommendations for the best tools, you’ll find valuable insights from fellow woodworkers who have been in your shoes.

Additionally, woodworking communities offer networking opportunities. Building connections with other woodworkers can lead to exciting collaborations, joint projects, and even potential business prospects. By being part of a community, you get the chance to meet like-minded individuals who share your passion for woodworking.

Finding resources is another advantage of being part of a woodworking community. Many communities have dedicated websites or forums where members can access a wide range of resources such as project plans, instructional videos, and articles on various woodworking topics. These resources can greatly enhance your skills and knowledge by providing guidance on specific techniques or showcasing innovative design ideas.

Conclusion

In conclusion, building your own woodworking shop is a rewarding and fulfilling experience. Throughout this article, we have discussed the importance of having a woodworking shop, as well as the factors to consider when selecting the right location and designing an efficient layout. We have also explored the essential tools and equipment needed for success in woodworking, along with strategies for creating a clean and healthy working environment.

One of the key takeaways from this article is the significance of proper ventilation and air filtration in your woodworking shop. By ensuring good air quality, you can protect your health and enhance overall comfort while working on your projects. Additionally, we have emphasized the importance of safety measures and personal protective equipment to maintain a secure working environment.

Lastly, building a community and finding resources through networking opportunities can greatly improve your skills as a woodworker. Joining woodworking communities or attending workshops can provide valuable insights and inspiration to help you continuously grow in your craft.

Now that we have covered all these important aspects of building a woodworking shop, it’s time for you to take action. Start by taking the first step towards creating your dream workspace. Consider the tips and techniques shared in this article to guide you along the way.

Building your own woodworking shop will not only provide you with a dedicated space for pursuing your passion but also serve as a sanctuary where creativity flourishes. Remember, with dedication, patience, and perseverance, you can achieve great things in woodworking. So go ahead – get started on making your dreams come true.

Frequently Asked Questions

How to build a wood work shop?

Building a woodwork shop requires careful planning and consideration of a few key aspects. First, determine the location for your workshop, ensuring it has enough space to accommodate all your woodworking activities and equipment. Next, focus on setting up an efficient layout that optimizes workflow and provides ample storage for tools and materials.

Consider factors like proper lighting, ventilation, and electrical requirements to ensure safety and comfort in your shop. Additionally, carefully select the necessary workbenches, tables, shelving units, and cabinets to organize your tools effectively. Finally, invest in essential woodworking tools such as a table saw, miter saw, planer, jointer, band saw, drill press, router table, sanders, clamps, and more based on your specific woodworking needs.

Are woodworking shops profitable?

Woodworking shops can be profitable if managed properly with a strategic approach to both production and business operations. However, profitability depends on various factors such as the level of demand for custom or handcrafted wood products in your area or market niche. Identifying target customers or focusing on specific markets can help increase profitability potential.

Offering unique or high-quality designs that resonate with customers will also contribute to the shop’s success. Efficiently managing costs by sourcing materials at competitive prices while maintaining quality standards is crucial. Furthermore, effective marketing strategies like online presence through websites or social media platforms can help to reach a broader audience and drive sales.

What machines do I need in a woodworking shop?

The machines needed in a woodworking shop depend on the scale of projects you plan to undertake and the level of complexity desired in your woodworking creations. However, some essential machines commonly found in woodworking shops include a table saw which allows precise cutting of wood pieces with variable blades as per required dimensions.

A miter saw helps make accurate crosscuts and angles quickly while a planer is useful for creating smooth surfaces from rough lumber by reducing thickness consistently across the board’s width.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.