Are you interested in learning how to build woodworking tools? Woodworking is a timeless craft that has been passed down through generations, and there is something special about creating your own tools to use for your woodworking projects. In this article, we will explore the art of building woodworking tools, from understanding the different types of tools to selecting the right materials and equipment needed for their construction.

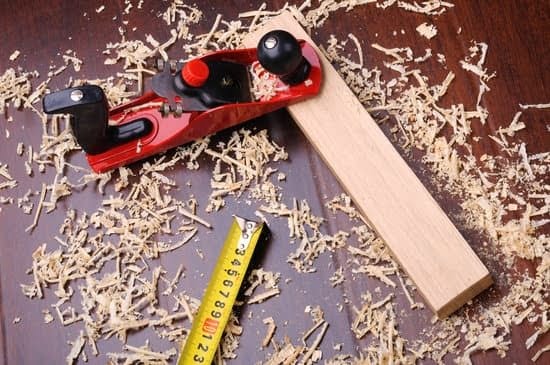

Woodworking tools come in various shapes and sizes, each serving a unique purpose in the creation of wooden masterpieces. Whether it’s a hand plane for smoothing out rough surfaces or a wooden mallet for chiseling and shaping wood, knowing how to build these tools can enhance your woodworking experience and give you a sense of pride in using what you’ve created.

In the following sections, we will delve into the different types of woodworking tools, discuss the materials needed for their construction, provide a step-by-step guide on building a hand plane, share tips for crafting a wooden mallet, and offer insights on building a customized workbench. Additionally, we will cover safety precautions and maintenance tips to ensure that your handmade woodworking tools last for years to come.

So let’s embark on this journey together as we embrace the craft of building our own woodworking tools.

Understanding the Different Types of Woodworking Tools

Woodworking tools come in a variety of types, each designed to serve a specific purpose in the woodworking process. These tools can be categorized into hand tools and power tools. Hand tools include saws, chisels, planes, and carving tools, while power tools include drills, sanders, routers, and table saws. Each type of tool has its own unique function and benefits, so it’s important to understand the differences in order to choose the right tool for the job.

Saws are essential woodworking tools used for cutting wood into different shapes and sizes. They come in various types such as hand saws, circular saws, and bandsaws. Chisels are another important tool used for carving and shaping wood. They come in different widths and shapes to accommodate different woodworking tasks.

Planes are used for smoothing and flattening wooden surfaces. There are different types of planes including block planes, jack planes, smoothing planes, and jointer planes. Carving tools such as gouges and chisels are used for intricate wood carving projects. It’s important to understand how each type of woodworking tool works in order to make informed decisions when building or using them.

When building your own woodworking tools, understanding the different types available will help you determine which ones you need based on the projects you plan to work on.

| Types of Woodworking Tools | Description |

|---|---|

| Saws | Cutting wood into different shapes and sizes |

| Chisels | Carving and shaping wood |

| Planes | Smoothing and flattening wooden surfaces |

Selecting the Right Materials for Building Woodworking Tools

When it comes to building woodworking tools, the choice of materials is crucial in determining the quality and performance of the finished product. Here are some essential materials you will need to consider when building your own woodworking tools:

1. Hardwood: Hardwood such as oak, maple, cherry, and walnut are ideal for building woodworking tools due to their durability and strength. These materials can withstand the heavy use that comes with woodworking projects and can provide a solid foundation for your tools.

2. High Carbon Steel: When it comes to creating cutting edges for tools such as hand planes and chisels, high carbon steel is the preferred material. It can hold a sharp edge for longer periods, making it perfect for creating precise cuts and smooth finishes on wood.

3. Brass or Stainless Steel: For components that require strength and corrosion resistance, such as plane bodies or saw nuts, brass or stainless steel are excellent choices. These materials can withstand the wear and tear of woodworking activities while maintaining their structural integrity.

4. Wood Finish: Once you have built your woodworking tools, applying a protective finish is crucial to prolong their lifespan. Linseed oil or Danish oil are popular choices for finishing wooden handles and bodies, as they provide a durable and water-resistant coating.

By carefully selecting these materials, you can ensure that your DIY woodworking tools are not only functional but also durable enough to withstand the demands of various projects.

For more tips on how to build woodworking tools, consult reputable resources such as educational websites, instructional books, or even consider taking a hands-on workshop on crafting your own custom woodworking tools. With sufficient knowledge and practice, anyone can learn how to build finely-crafted woodworking tools that meet their specific project needs.

Essential Tools and Equipment Needed for Building Woodworking Tools

Building woodworking tools can be a rewarding and fulfilling experience for any woodworker. However, in order to successfully create your own woodworking tools, you will need to have the essential tools and equipment at your disposal. These tools are crucial in shaping, cutting, and assembling the different components of woodworking tools. Some of the essential tools needed for building woodworking tools include chisels, saws, drills, clamps, and sanders.

Chisels are important for carving and shaping wood to create intricate designs and details on the surface of the woodworking tool. Saws are used for cutting wood into different shapes and sizes according to the design requirements. Drills come in handy for creating holes and openings where necessary, while clamps are essential for holding the different parts of the tool together during assembly. Sanders are used to smoothen out any rough edges or surfaces on the woodworking tool.

In addition to these hand tools, having access to power tools such as a table saw, band saw, drill press, and power sander can make the process of building woodworking tools more efficient and precise. These power tools can help you make accurate cuts, create precise holes, and achieve a smooth finish on your wooden creations.

| Woodworking Tool | Essential Tools Needed |

|---|---|

| Hand Plane | Chisels, Saws, Sanders |

| Wooden Mallet | Chisels, Clamps |

| Workbench | Saws, Clamps, Power Drill |

Step-by-Step Guide on How to Build a Hand Plane

Building a hand plane is a rewarding and useful project for any woodworker. A hand plane is an essential woodworking tool that allows you to smooth and shape wood with precision. Whether you’re a beginner or a seasoned woodworker, creating your own hand plane can be a fulfilling experience. Below, we’ll provide a step-by-step guide on how to build your own hand plane.

Gather Materials and Tools

Before you begin building your hand plane, gather the necessary materials and tools. You will need a hardwood block for the body of the plane, a metal blade for the cutting edge, and brass pins to secure the blade in place. Additionally, you will need woodworking tools such as saws, chisels, and sandpaper to shape and refine the components of the hand plane.

Cut and Shape the Body of the Plane

Start by cutting the hardwood block to the desired length and width for your hand plane. Then, carefully shape it using saws and chisels to achieve a smooth, flat surface. Next, create an opening at one end of the block where the blade will be inserted. This opening should be slightly wider than the width of the blade to allow for easy adjustment.

Assemble and Fine-Tune

Once you have shaped the body of the hand plane, insert the metal blade into the opening and secure it in place with brass pins. Make sure that the blade sits flush with the sole of the plane to ensure proper functionality. Finally, fine-tune your hand plane by sanding down any rough edges and adjusting the depth of cut as needed.

By following these steps, you can create a custom hand plane that meets your specific woodworking needs while gaining valuable experience in crafting your own woodworking tools.

Tips for Crafting a Wooden Mallet for Woodworking Projects

Crafting your own wooden mallet for woodworking projects can be a rewarding and practical endeavor. Not only will it give you a sense of accomplishment, but it will also provide you with a valuable tool for your future woodworking projects. Here are some tips to guide you through the process of building a wooden mallet for your woodworking needs.

Choosing the Right Wood

The first step in crafting a wooden mallet is selecting the right type of wood. Hardwoods like maple, oak, or beech are ideal choices due to their durability and resistance to wear and tear. These types of wood will ensure that your mallet can withstand the force necessary for driving chisels and other tools without easily denting or breaking.

Design and Dimensions

Once you have chosen the type of wood, decide on the design and dimensions of your mallet. A classic design consists of a cylindrical handle attached to a larger head. The dimensions may vary depending on personal preference, but typically, a good size for the head would be around 4-6 inches in length and width, with the handle being approximately 10-12 inches long.

Assembly and Finishing

After cutting the wood to the desired dimensions, assemble the pieces using glue and clamps to secure them together. Once dry, shape the handle as well as round off any sharp edges or corners on the head. Finally, sand down any rough spots and finish it off with varnish or oil to protect the wood from moisture and provide a smooth surface for gripping.

Crafting your own wooden mallet is just one example of how rewarding it can be to build your own woodworking tools. With some basic knowledge, patience, and creativity, you can create custom tools that not only serve their purpose but also reflect your unique craftsmanship.

Building a Customized Workbench for Woodworking Tools

When it comes to woodworking, having a sturdy and customized workbench is essential for a successful and efficient woodworking project. A well-built workbench not only provides a stable surface for your woodworking tools but also offers storage and organization solutions for your workspace. Here is a step-by-step guide on how to build your own customized workbench for woodworking tools:

Materials Needed:

- 4 pieces of 4×4 lumber (for the legs)

- 4 pieces of 2×4 lumber (for the frame)

- 2 pieces of plywood (for the tabletop)

- Wood screws

- Wood glue

- Measuring tape

- Saw

- Drill

- Sandpaper

- Wood finish/varnish

Steps:

- Begin by cutting the 4×4 lumber to the desired height of your workbench legs. Typically, a good starting point is around 34 inches, but you can customize it based on your preference and comfort.

- Next, cut the 2×4 lumber to create the frame of the workbench. This will involve creating a rectangular frame that will support the tabletop and provide stability to the overall structure.

- Assemble the legs and frame using wood glue and screws. Ensure that everything is squared up properly before attaching them together.

- Once the base is constructed, measure and cut the plywood to fit as the tabletop. You may want to consider adding an overhang on all sides for clamping purposes.

Building your own customized workbench for woodworking tools allows you to tailor it specifically to your needs and preferences, creating an efficient and ergonomic space for all your projects.

Safety Precautions and Maintenance Tips for Woodworking Tools

Woodworking tools are essential for any woodworker, whether they are a beginner or seasoned professional. However, it is important to prioritize safety when using these tools to ensure the protection of oneself and others. Before building your own woodworking tools, it is crucial to be well-versed in safety precautions and maintenance tips.

When building and using woodworking tools, one must always wear appropriate personal protective equipment such as safety goggles and hearing protection. Additionally, it is vital to keep the work area clean and well-lit to minimize hazards that could cause accidents. Proper tool maintenance is also key in ensuring safety, as regularly sharpening blades and keeping tools clean can prevent accidents caused by dull or malfunctioning equipment.

In addition to safety precautions, maintaining woodworking tools can also prolong their lifespan and ensure their efficiency in crafting woodwork. It is important to store tools in a dry place to prevent rusting, and regularly oiling moving parts can prevent friction that leads to wear and tear. Proper storage will also make it easier to find the necessary tool for specific projects.

Regular inspection of woodworking tools can also help identify any potential issues before they escalate into more serious problems. By taking the time to maintain these essential instruments, woodworkers can protect themselves while ensuring their creations turn out as intended.

Conclusion

In conclusion, embracing the craft of building your own woodworking tools can be a rewarding and fulfilling experience for any woodworking enthusiast. Understanding the different types of woodworking tools and selecting the right materials is essential in creating functional and efficient tools.

With the essential tools and equipment needed for building woodworking tools, along with the step-by-step guide on how to build a hand plane, crafting a wooden mallet for woodworking projects, and building a customized workbench, anyone can take their woodworking skills to the next level.

By learning how to build woodworking tools, individuals can have greater control over the quality and functionality of their equipment. It also allows for customization based on personal preferences and specific project needs. Additionally, knowing how to build woodworking tools provides an opportunity for woodworkers to develop new skills and techniques that will enhance their overall craft.

Overall, safety precautions and maintenance tips are crucial when working with woodworking tools. It is important to prioritize safety in order to prevent accidents and injuries. By following these guidelines, woodworkers can enjoy their craft while minimizing risks. With dedication and practice, anyone can master the art of building their own woodworking tools and elevate their woodworking projects to new heights.

Frequently Asked Questions

What Tools Do You Need to Build With Wood?

Building with wood requires a variety of tools, including hand tools such as saws, chisels, planes, hammers, and screwdrivers. Power tools like a table saw, miter saw, drill press, and power sander are also essential. Clamps, measuring tools, and safety equipment like goggles and gloves are important for precision and protection.

What Do I Need to Start Woodworking at Home?

To start woodworking at home, you will need the basic hand tools mentioned earlier along with some essential power tools such as a drill/driver, circular saw, and orbital sander. A workbench or sturdy table to work on is also necessary for stability.

Additionally, having access to a good set of plans or guides for beginner projects can help you get started with building confidence.

How to Get Free Woodworking Tools?

It is possible to acquire free woodworking tools through several avenues. One way is to look for local woodworking clubs or groups where members may be willing to donate or lend out unused tools.

Another option is to keep an eye on online marketplaces or community bulletin boards where people may be giving away items they no longer need. Additionally, reaching out to friends or family members who may have woodworking tools they’re not using could also yield some free resources for your new hobby.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.