Are you looking to improve your woodworking skills and create more accurate and precise angles in your projects? Understanding how to figure angles for woodworking is essential for achieving professional-looking results. Whether you’re a beginner or an experienced woodworker, knowing the techniques for measuring, calculating, and cutting angles can make a significant difference in the quality of your work.

Accurate angles are crucial in woodworking as they directly impact the structural integrity and overall appearance of the finished piece. From building furniture to constructing intricate designs, having the knowledge and ability to figure angles correctly is fundamental. In this article, we will explore the necessary tools, step-by-step guides, common mistakes to avoid, and advanced techniques for figuring angles in woodworking.

By learning how to measure, calculate, and cut angles accurately, you’ll be able to take on more complex projects with confidence and precision. Whether you’re building cabinets, crafting decorative moldings, or constructing frames, understanding the importance of accurate angles in woodworking is a game-changer. Let’s dive into the world of figuring angles for woodworking and elevate your craftsmanship to the next level.

Tools Needed

When it comes to woodworking, one of the most important aspects is ensuring that angles are measured and cut accurately. To achieve this, it is essential to have the right tools on hand. Here is a comprehensive list of tools required to measure and cut angles for your woodworking projects.

One essential tool for measuring angles is a combination square. This versatile tool can be used to measure and mark 90-degree angles, as well as check for squareness and transfer measurements. Another must-have item is a bevel gauge, which is specifically designed for measuring and transferring angles. It allows woodworkers to easily set and duplicate both bevel and miter angles.

For more precise measurements, a protractor or angle finder can be used to measure angles with great accuracy. These tools are especially useful when working with non-standard or unique angles. Additionally, a digital angle gauge can provide digital readouts of angles, making it easier to achieve precision in angle measurements.

Finally, having a reliable miter saw or table saw with an adjustable blade tilt feature is crucial for cutting accurate angles. When paired with the appropriate blades, these power tools can help you achieve clean and precise angled cuts in your woodworking projects.

| Tool | Use |

|---|---|

| Combination Square | Measure and mark 90-degree angles, check for squareness |

| Bevel Gauge | Measure and transfer bevel and miter angles |

| Protractor/Angle Finder | Measure non-standard or unique angles with great accuracy |

| Digital Angle Gauge | Provide digital readouts of angles for precision measurements |

Measuring Angles

Protractor and Angle Finder

One of the most common tools used to measure angles in woodworking is a protractor and angle finder. These tools are simple to use and can be used to measure both inside and outside angles.

To use a protractor, place the center hole of the tool at the vertex of the angle, align one edge of the protractor along one of the lines forming the angle, and then read the measurement where the other line crosses the scale on the protractor.

Bevel Gauge

A bevel gauge is another essential tool for measuring angles in woodworking. It consists of a handle attached to a metal blade with an adjustable scale or mechanism. To use a bevel gauge, loosen the locking mechanism, adjust the blade to your desired angle, lock it in place, and then transfer the measurement directly onto your workpiece.

Digital Angle Gauge

For more precise measurements, consider investing in a digital angle gauge. This tool provides digital readouts for accuracy and often has magnetic bases or other features that make it easy to attach to saw blades, jointer fences, and other surfaces for accurate angle measurement.

With these various tools at your disposal, you can easily measure angles accurately for your woodworking projects. Mastering these techniques will ensure that your cuts are precise and fit together seamlessly to create beautiful finished products.

Calculating Angles

Accurately calculating angles is crucial for any woodworking project to ensure a perfect fit and precise assembly. Whether it’s creating a bevel edge, joining two pieces at an angle, or constructing complex shapes, understanding how to calculate angles is essential for any woodworker. In this section, we will explore different techniques for calculating angles for various woodworking projects.

One of the simplest methods for determining angles is by using a protractor. This tool allows you to measure the angle between two intersecting lines accurately. For instance, if you need to cut a piece of wood at a specific angle, you can use a protractor to measure the exact degrees and then transfer that measurement onto your workpiece.

Another technique for calculating angles in woodworking is the use of trigonometric functions such as sine, cosine, and tangent. These mathematical principles can be particularly useful when dealing with complex angled cuts or creating intricate designs. By applying these functions, woodworkers can calculate the precise measurements required to achieve their desired angles.

Additionally, there are specialized tools such as digital angle finders that provide accurate measurements of angles in woodworking. These devices eliminate the need for manual calculations and ensure precision in determining angles for miter cuts, bevels, and other angular adjustments in woodworking projects.

| Technique | Application |

|---|---|

| Protractor | Measuring angle between two intersecting lines |

| Trigonometric Functions | Calculating precise measurements for complex angled cuts |

| Digital Angle Finders | Precision in determining miter cuts and bevels |

Cutting Angles

When it comes to woodworking, cutting precise angles is essential in ensuring that all pieces fit together perfectly and the finished product looks professional. There are several cutting tools that can be used to achieve accurate angles, and knowing how to use them effectively is key to a successful woodworking project.

One of the most common tools for cutting angles in woodworking is the miter saw. This versatile tool allows for precise angle cuts by rotating the blade to the desired angle and securing the stock in place before making the cut. Miter saws also have built-in angle gauges that make it easier to set and lock in specific angles for accurate cuts.

For more intricate angle cuts, a table saw equipped with a miter gauge or a crosscut sled can be used. These tools allow woodworkers to make precise angled cuts by guiding the stock through the blade at the desired angle. It’s important to ensure that the stock is securely held in place and that the cutting blade is properly adjusted to achieve clean, accurate cuts.

Another option for cutting angles in woodworking is using a handheld circular saw equipped with an adjustable base. This allows woodworkers to make angled cuts on larger pieces of stock or even on uneven surfaces. By adjusting the base of the circular saw to the desired angle and using a guide or fence as a reference, accurate angled cuts can be achieved.

Learning how to figure angles for woodworking projects not only requires an understanding of measurement and calculation but also proficiency in using various cutting tools effectively. By mastering these techniques, woodworkers can ensure that their projects are executed with precision and attention to detail.

Common Mistakes

When it comes to woodworking, figuring angles accurately is crucial for the success of any project. However, there are some common mistakes that beginners and even experienced woodworkers can make when measuring, calculating, and cutting angles. In this section, we will discuss some of these common mistakes and provide tips on how to avoid them.

1. Incorrect Measurement: One of the most common mistakes when figuring angles for woodworking is taking inaccurate measurements. This can result in misaligned cuts and a poor fit for joints. To avoid this mistake, always use a reliable angle measuring tool such as a protractor or combination square. Double-check your measurements before making any cuts to ensure accuracy.

2. Neglecting Wood Grain: Another common mistake is neglecting the direction of the wood grain when cutting angles. Failing to consider the wood grain can result in splintering or tear-out, especially when cutting across the grain. Always pay attention to the direction of the wood grain and adjust your cutting technique accordingly to achieve clean and precise cuts.

3. Poor Cutting Technique: Using improper cutting techniques can also lead to inaccuracies when cutting angles for woodworking projects. Whether using a circular saw, miter saw, or hand saw, make sure to follow proper cutting guidelines and maintain a steady hand to achieve precise cuts without any errors.

By being aware of these common mistakes and following the tips provided in this section, you can improve your accuracy when figuring angles for woodworking projects and achieve professional results in your finished pieces.

Advanced Techniques

Woodworking often involves more than just simple, straight cuts. As you progress in your woodworking skills, you may encounter projects that require complex angles and intricate cuts. In this section, we will explore some advanced techniques for tackling these more challenging aspects of woodworking.

Understanding Compound Angles

One of the most common advanced techniques in woodworking involves dealing with compound angles. A compound angle is a combination of two or more basic angles, and it can be quite daunting to figure out. To tackle compound angles, it’s important to break them down into their individual components and work on each angle separately. This may involve using specialized tools like a bevel gauge or a digital protractor to accurately measure the angles before making your cuts.

Using Jigs and Templates

When faced with intricate cuts that need to be repeated multiple times, using jigs and templates can be extremely helpful. A jig is a custom-made tool that helps guide your cutting tool to make precise cuts at specific angles.

Templates, on the other hand, are patterns or guides that can be used to replicate complex shapes and angles consistently. By creating and using jigs and templates, you can ensure that your intricate cuts are accurate and uniform across multiple pieces.

Employing Advanced Cutting Techniques

In addition to using specialized tools and guides, employing advanced cutting techniques can also help in making intricate cuts with complex angles. Techniques such as mitering, beveling, or even utilizing a table saw sled for angled crosscuts can all contribute to achieving precision in your woodworking projects. These advanced cutting techniques may require practice and patience but can ultimately result in beautifully crafted pieces with flawless angles.

By mastering these advanced techniques, woodworkers can confidently take on more challenging projects that require complex angles and intricate cuts. Whether it’s constructing an elaborate piece of furniture or creating finely detailed trim work, understanding how to figure angles for woodworking is essential for achieving professional-quality results.

Examples and Applications

In conclusion, understanding how to figure angles for woodworking is essential for achieving precision and accuracy in various projects. From measuring and calculating angles to cutting precise angles, the process requires the right tools and techniques to ensure successful outcomes. By following a step-by-step guide and avoiding common mistakes, woodworkers can achieve the desired results in their projects.

One of the key aspects of mastering the art of figuring angles for woodworking is having a comprehensive understanding of the tools needed for accurate measurements and cuts. Whether it’s using a protractor, bevel gauge, or miter saw, each tool plays a crucial role in achieving the desired angle for a woodworking project. Additionally, learning advanced techniques can further enhance one’s ability to tackle complex angles and make intricate cuts with ease.

Real-life examples and applications demonstrate the practical significance of figuring angles in woodworking projects. From constructing furniture to building structures, precise angles are vital for ensuring stability and aesthetic appeal. With the knowledge gained from this comprehensive guide on how to figure angles for woodworking, woodworkers can confidently take on a wide range of projects with precision and success.

Frequently Asked Questions

How Do You Find the Angle of Woodworking?

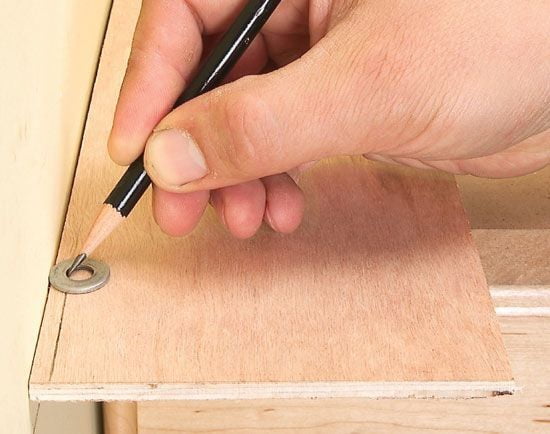

In woodworking, finding the angle can be done using a combination square or a protractor. Placing the tool against the wood allows you to accurately measure and mark the desired angle for cutting.

What Is the Formula for Cutting Angles?

The formula for cutting angles depends on the type of angle you are trying to achieve. For a right angle (90 degrees), no calculation is needed. For other angles, trigonometric functions like sine, cosine, or tangent may be used to calculate the angle.

How to Calculate Angles?

To calculate angles, you can use a protractor or a speed square to measure the angle directly. If you need to calculate an angle mathematically, trigonometric functions can help determine the angle based on the sides of a triangle or other geometric shapes.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.