A woodworking vise is an essential tool for any woodworker, whether you’re a beginner or an experienced craftsman. It provides critical stability and security when working on various woodworking projects, ensuring that your workpiece stays firmly in place as you shape, cut, and join the wood. This section will discuss the importance of a woodworking vise and its versatile applications in the world of woodworking.

A woodworking vise serves as an extra set of hands, allowing you to work efficiently and safely. It can hold pieces tightly together during glue-ups or provide a secure grip for sanding and shaping wooden surfaces. Whether you’re building furniture, cabinets, or smaller decorative items, a woodworking vise is indispensable for achieving precise and accurate results.

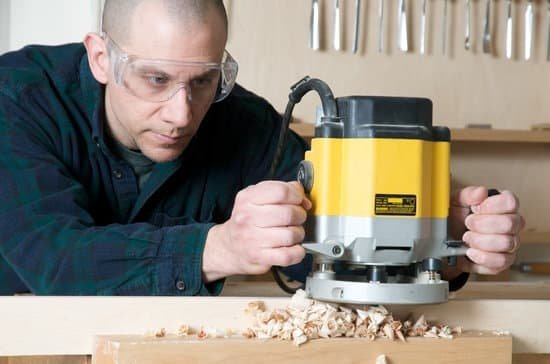

Furthermore, the versatility of a woodworking vise extends beyond traditional carpentry tasks. It can be used in conjunction with other tools such as hand planes, routers, and saws to expand your creative possibilities. From creating intricate joinery to planing rough lumber surfaces, the woodworking vise opens up a world of opportunities for woodworkers of all skill levels.

In the upcoming sections of this article, we’ll explore different types of vises available in the market and their specific uses. We’ll also delve into factors to consider when selecting the right woodworking vise for your needs. Additionally, we’ll provide step-by-step instructions on how to set up your workbench with a vise and cover various techniques for positioning and clamping workpieces effectively to achieve optimal stability and safety.

So whether you’re just starting out in woodworking or looking to enhance your skills, learning how to use a woodworking vise is crucial. With this versatile tool at your disposal, you can tackle a wide range of projects with confidence and precision.

Understanding the types of woodworking vises

Woodworking vises come in various types, each designed for specific purposes and applications. Understanding the different types of vises available in the market can help woodworkers choose the right one for their needs.

- Front Vise: A front vise, also known as a face vise or shoulder vise, is commonly found on the front edge of a workbench. It is typically used to hold larger workpieces securely in place during various woodworking tasks such as planing, sawing, and routing. The front vise operates by using a screw mechanism that closes the jaws together to hold the workpiece.

- End Vise: An end vise, also referred to as a tail vise or wagon vise, is usually located at one end of the workbench. It is designed to hold longer workpieces by clamping them between its jaws. This type of vise is particularly useful when performing tasks like dovetailing or hand planing where support throughout the entire length of the workpiece is required.

- Bench Vises: Bench vises are versatile tools that can be mounted on any part of the workbench surface. They come in various sizes and designs, including quick-release bench vises and pipe jaw bench vises. These vises provide flexibility and ease of use when holding smaller workpieces or performing delicate woodworking operations.

- Wood Vises: Wood vises are specifically designed for gripping wood securely without damaging its surfaces. They often feature wooden jaws that are adjustable to accommodate different thicknesses of wood stock. Wood vises are commonly used for joinery tasks like gluing boards together or fitting mortises and tenons.

Regardless of the type chosen, it is essential to consider factors such as material quality, durability, ease of use, and jaw size when selecting a woodworking vise. Each type has its own strengths and limitations based on specific applications, so it’s important to evaluate your woodworking needs and choose the one that best suits your work style and requirements.

Selecting the right woodworking vise

When it comes to selecting the right woodworking vise for your needs, there are several important factors to consider. The size, material, and quality of the vise can greatly impact its performance and durability. By carefully considering these factors, you can ensure that you choose a vise that will meet your specific requirements and provide years of reliable use.

- Size: The size of the woodworking vise is one of the first things to consider. A larger vise may be capable of holding larger workpieces, but it may also take up more space on your workbench. It’s important to strike a balance between the size of the vise and the available workspace you have.

- Material: Woodworking vises are typically made from either cast iron or steel. Cast iron vises are solid, stable, and durable, but they can be heavy and may require more maintenance to prevent rusting. Steel vises are also strong and reliable, but they tend to be lighter in weight and easier to maintain.

- Quality: The quality of the woodworking vise is crucial in ensuring its functionality and longevity. Look for vises that are well-built with robust construction, smooth operation, and precision alignment mechanisms. It’s worth investing in a high-quality vise that will withstand heavy use and provide consistent clamping pressure.

In addition to these main factors, there are other features that you may want to consider depending on your specific needs. Some vises come with quick-release mechanisms that allow for rapid adjustment or removal of workpieces. Others may have built-in bench dogs or dog holes for added versatility when clamping irregularly shaped objects.

By taking into account these factors when selecting a woodworking vise, you can make an informed decision that will best suit your woodworking needs. Remember to also consider your budget constraints while aiming for the best quality possible within your price range.

Setting up your workbench for the woodworking vise

Gather the necessary tools and materials

Before you can begin setting up your workbench for a woodworking vise, it is important to gather all the necessary tools and materials. Here is a list of items you will need:

- Woodworking vise: Make sure you have chosen the appropriate type and size of vise for your specific woodworking needs.

- Workbench: Ensure that your workbench is sturdy and stable enough to support the weight of the vise and withstand the force applied during woodworking tasks.

- Mounting hardware: This includes screws, bolts, washers, and nuts that are suitable for attaching the vise to your workbench.

- Measuring tape or ruler: These tools will help you accurately measure and mark where the vise should be installed on your workbench.

- Drill or screwdriver: Depending on the type of mounting hardware used, you will need either a drill or a screwdriver to attach the vise to your workbench.

- Safety equipment: Don’t forget to wear safety goggles and gloves throughout this setup process to protect yourself from potential hazards.

Determine the ideal location for your woodworking vise

Once you have gathered all the necessary tools and materials, it’s time to determine where on your workbench to install the woodworking vise. Consider these factors when choosing a location:

- Comfortable working height: The top of the jaws of the vise should be at a comfortable working height so that you can easily access and manipulate your workpiece without straining.

- Ample space around the vise: Allow sufficient space around your vise for maneuverability while working on larger or longer pieces of wood.

- Accessibility to other tools: Positioning your woodworking vise near other frequently used tools, such as saws or planes, can improve efficiency by minimizing movement between different tasks.

- Stability and strength: Identify a solid and stable area of the workbench where you can securely attach the vise without compromising the integrity of your work surface.

Attach and secure the vise to your workbench

Once you have determined the ideal location for your woodworking vise, it’s time to attach and secure it to your workbench. Follow these step-by-step instructions:

- Position the vise: Place the vise on your workbench in the desired location, ensuring that its jaws are facing upward.

- Mark the mounting holes: Use a measuring tape or ruler to mark where the mounting holes of the vise will be drilled into your workbench. These marks should align with holes or recessed areas in the vise base.

- Drill pilot holes: With a drill and an appropriate-sized bit, carefully drill pilot holes into each marked spot on your workbench. Pilot holes help prevent wood from splitting when you insert screws or bolts later.

- Attach the vise: Line up the mounting holes of the vise with the pilot holes on your workbench, then use screws or bolts to attach and secure them together. Tightly fasten washers and nuts on the opposite side of each screw or bolt head.

- Test for stability: Once the vise is attached, test its stability by applying pressure on both sides of its jaws. If there is any wobbling or movement, tighten any loose screws or bolts until it feels sturdy and secure.

By following these step-by-step instructions, you can properly attach and secure a woodworking vise to your workbench, creating a reliable workspace for various woodworking projects.

Proper positioning and alignment

Proper positioning and alignment of the workpiece in a woodworking vise is crucial for achieving optimal stability and safety during woodworking projects. By using the right techniques, woodworkers can ensure that their workpieces are securely held in place, allowing for precise and controlled cuts or shaping. This section will provide step-by-step instructions on how to position and align workpieces in a woodworking vise, ensuring both stability and safety.

Step 1: Assessing the Workpiece

Before securing your workpiece in the vice, it’s essential to evaluate its shape, size, and condition. Consider any irregularities or flaws that may affect the stability of the piece while it’s clamped in the vise. If necessary, make any necessary adjustments or preparations to your workpiece before moving forward.

Step 2: Positioning the Workpiece

To properly position your workpiece in the vise, start by placing it horizontally on top of the jaw of the vise. Ensure that the edge you want to work on is facing upward towards you. Align one end of the workpiece with one side of the jaw so that it is parallel to one face of your bench. This alignment will help provide more support when working on longer pieces.

Step 3: Clamping the Workpiece

Once you have positioned your workpiece correctly, slowly lower it into the jaws of your woodworking vise. Use light pressure initially to prevent any slippage or movement from occurring during clamping. As you tighten the vise, ensure that pressure is distributed evenly across all points where contact is made between the jaw and your workpiece.

Safety Considerations

When positioning and clamping your workpiece in a woodworking vise, always prioritize safety. Avoid placing your hands or fingers too close to sharp edges or cutting tools while adjusting the position of your workpiece. Additionally, make sure that the vise is securely attached to a stable workbench to prevent any accidents or injuries caused by instability.

By following these techniques for proper positioning and alignment, woodworkers can ensure that their workpieces are securely held in place, allowing for precise and controlled woodworking. Remember to take into account the specific requirements of each project and adjust your techniques accordingly. With practice and experience, you will become more proficient in using a woodworking vise to achieve optimal stability and safety during your woodworking endeavors.

Basic techniques for using a woodworking vise

When it comes to using a woodworking vise, there are certain basic techniques that every woodworker should be familiar with. These techniques involve clamping, holding, and securing workpieces in the vise to ensure stability and safety during the woodworking process.

The first technique is clamping the workpiece in the vise. To do this, you will need to open the jaws of the vise wide enough to accommodate the size of your workpiece. Place the workpiece between the jaws, making sure it is centered and aligned properly.

Use the handle or crank on the vise to tighten the jaws around the workpiece until it is securely held in place. It’s important to apply even pressure on both sides of the workpiece to prevent any shifting or movement.

The second technique involves holding smaller pieces in the vise. Sometimes you may have smaller pieces that need to be held securely for carving, sanding, or other tasks. In this case, you can use wooden blocks or scraps as support fixtures. Simply position these blocks or scraps on either side of your small workpiece and tighten the vise jaws around them. This will provide a stable platform for working on small pieces without damaging them.

Lastly, securing irregularly shaped or round workpieces can be a challenge. A useful technique is using soft jaws or jaw inserts specifically designed for gripping non-flat surfaces. These soft jaws or inserts have grooves or ridges that conform to irregular shapes and provide better grip and stability when working with odd-shaped pieces.

By mastering these basic techniques for using a woodworking vise, you will be able to hold your workpieces securely and safely during various woodworking operations. Remember to always double-check that your workpiece is tightly clamped before starting any cutting, drilling, or shaping process to prevent accidents and ensure accurate results in your woodworking projects.

Advanced techniques and tips for enhancing your woodworking vise experience

Woodworking vises are not only useful for basic clamping and holding tasks but can also be utilized for more advanced techniques to enhance your woodworking experience. By harnessing the versatility of a woodworking vise, you can achieve precision and efficiency in various woodworking processes such as hand planing, routing, and joinery.

One advanced technique that can be accomplished using a woodworking vise is hand planing. By securely clamping your workpiece in the vise, you have a stable surface to work on. This allows you to apply consistent pressure while planing, resulting in smoother and more even surfaces. Additionally, by angling the workpiece within the vise, you can easily create chamfers or bevels on the edges of your project.

Another way to enhance your woodworking with a vise is by utilizing it for routing tasks. Whether you’re creating decorative edges or precise mortises, a woodworking vise can provide the necessary stability for accurate routing. By firmly securing the workpiece in the vise, you can confidently guide the router along the desired path without worrying about movement or slippage.

Furthermore, joinery tasks can be significantly improved with the help of a woodworking vise. When creating joints such as dovetails or finger joints, it is crucial to have precise alignment and tight clamping. A well-maintained vise can ensure that your workpieces remain firmly held together during glue-ups or while making accurate cuts.

| Advanced Techniques | Description |

|---|---|

| Hand Planing | This technique utilizes a secure clamp in the woodworking vise to achieve consistent pressure and smoother surfaces. |

| Routing | A woodworking vise provides stability for accurate routing, allowing for precise decorative edges or mortises. |

| Joinery | Tight clamping and precise alignment can be achieved with a woodworking vise when creating dovetails or finger joints. |

By incorporating these advanced techniques into your woodworking projects, you can elevate the quality of your craftsmanship and expand your creative possibilities. Remember to always prioritize safety and practice these techniques with caution and proper technique. Experimenting with different applications of your woodworking vise will not only enhance your skills but also open up new avenues for creativity in your woodwork.

Common mistakes to avoid when using a woodworking vise

When it comes to using a woodworking vise, there are common mistakes that beginners and even experienced woodworkers can make. These mistakes can lead to inefficient work processes, compromised safety, and potentially damaged workpieces. By being aware of these mistakes and learning how to avoid them, you can ensure that you are getting the most out of your woodworking vise.

One common mistake is not properly securing the workpiece in the vise. It’s important to ensure that the workpiece is tightly and securely clamped in the vise before starting any woodworking task. Failure to do so can result in movement or shifting of the workpiece, leading to inaccurate cuts or potential injury. To avoid this mistake, always check that the workpiece is properly positioned and tightened in the vise before beginning any cutting or shaping.

Another mistake is applying excessive force when tightening the vise jaws. While it may seem like more force will provide a stronger grip on the workpiece, applying too much pressure can actually damage both the jaws of the vise and the workpiece itself.

It’s important to strike a balance between a secure grip and avoiding overtightening. A practical solution for this mistake is to tighten the jaws gradually, making small adjustments until you achieve a firm hold on your workpiece without causing any damage.

Finally, neglecting regular maintenance of your woodworking vise can lead to issues with its functionality over time. Failing to clean and lubricate the vise regularly can result in stiff or sticky movement of the jaws, making it difficult to clamp or release workpieces smoothly. To avoid this mistake, incorporate routine maintenance into your woodworking tasks by wiping down the vise with a clean cloth after each use and applying a thin layer of lubricant on any moving parts as needed.

By being mindful of these common mistakes and implementing the practical solutions provided, you can ensure that you are using your woodworking vise efficiently and effectively. Avoiding these errors will not only improve the quality of your work but will also contribute to a safer and more enjoyable woodworking experience.

| Mistake | Solution |

|---|---|

| Not properly securing the workpiece in the vise | Ensure tight and secure clamping of the workpiece before starting any task |

| Applying excessive force when tightening the vise jaws | Tighten jaws gradually, making small adjustments until achieving a firm hold without causing damage |

| Neglecting regular maintenance of the vise | Clean and lubricate regularly to prevent stiffness or stickiness in jaw movement |

Maintaining and caring for your woodworking vise

Once you have invested in a woodworking vise, it is crucial to take proper care of it to ensure its longevity and optimal performance. Regular maintenance will not only extend the life of your vise but also contribute to better woodworking results. Here are some essential tips on cleaning, lubricating, and performing routine maintenance for your woodworking vise.

First and foremost, keeping your woodworking vise clean is key to maintaining its functionality. After each use, make sure to remove any sawdust or debris that may have accumulated on the jaws or body of the vise. Use a stiff brush or compressed air to sweep away the particles. This step is especially important for wooden vises as sawdust can absorb moisture from the air and lead to swelling or warping.

Next, you should regularly lubricate all moving parts of your woodworking vise. Lubrication prevents rusting and ensures smooth operation. Apply a light coat of grease or oil to the screws, gears, and pivot points using a brush or cloth. Be sure to wipe off any excess lubricant afterward as it can attract more dust and dirt over time.

In addition to regular cleaning and lubrication, it is important to perform routine maintenance checks for any signs of wear or damage. Inspect the jaws for wear marks or dents that could affect their grip on workpieces. If necessary, use a file or sandpaper to smooth out any rough spots. Check the alignment of the jaws by clamping a straight edge against them – if there is any noticeable deviation from parallelism, it may be an indication that adjustments are needed.

By following these simple steps for maintaining and caring for your woodworking vise, you can ensure its longevity and optimal performance over time. Taking good care of your vise will not only save you money in the long run but also contribute to better woodworking results. Remember that a well-maintained vise is an essential tool that will help you achieve precision and efficiency in your woodworking projects.

Conclusion

In conclusion, a woodworking vise is an essential tool for any woodworker. Its versatile applications allow for a wide range of tasks to be completed with ease and precision. From clamping and holding workpieces to more advanced techniques such as hand planing and joinery, a woodworking vise provides stability, safety, and efficiency in every project.

Understanding the different types of vises available in the market is crucial in selecting the right one for your needs. Consider factors such as size, material, and quality to ensure that you have a vise that will withstand the demands of your projects. Additionally, proper setup and maintenance of your workbench are important for securely attaching and caring for your vise.

While basic techniques for using a woodworking vise are essential knowledge, there is always room for exploration and experimentation. Don’t be afraid to try out more advanced techniques and push the limits of what your vise can do. By avoiding common mistakes and regularly maintaining your vise, you can extend its lifespan and continue to benefit from its functionality.

Frequently Asked Questions

How do you use a wood vise?

A wood vise is a tool commonly used in woodworking to securely hold pieces of wood in place during various tasks. To use a wood vise, you first need to attach it to a sturdy work surface, such as a workbench or table, using screws or bolts. Position the jaws of the vise so that they are facing upward and open the jaws wide enough to accommodate the piece of wood you want to secure.

Place the piece of wood between the jaws, ensuring that it is positioned in the desired location and orientation. Close the jaws firmly by turning the handle or crank on the vise, applying even pressure on both sides of the piece of wood until it is securely held in place. This will provide stability and allow you to work on the wood with precision and safety.

What is the best position for a woodworking vise?

The best position for a woodworking vise largely depends on personal preference and the task at hand. However, there are some general guidelines to consider. For most bench-mounted vises, it is often recommended to install them on the front right corner if you are right-handed or on the front left corner if you are left-handed.

This placement allows for easy access to operate the vise while providing adequate clearance for your body when working with longer pieces of wood. Additionally, positioning it towards one end of your workbench provides more flexibility to secure longer pieces across its length if needed.

How do you set up a woodworking vise?

Setting up a woodworking vise involves several steps to ensure proper functionality and stability. Begin by marking where you want to mount your vise on your workbench or table. Use appropriate tools like a drill or chisel to create pilot holes for screws or bolts (depending on your specific vise). Attach one side of the vise firmly using screws/bolts before checking its alignment and levelness against your workspace using a spirit level or square tool.

Once aligned properly, fasten down all remaining screws/bolts securely without fully tightening just yet. Ensure the vise operates smoothly by opening and closing the jaws, making any minor adjustments if necessary. Finally, fully tighten all screws/bolts to firmly secure the vise in place, double-checking its alignment and stability once more. This setup process will help maximize the functionality of your woodworking vise and provide a solid foundation for your woodworking tasks.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.