CNC woodworking machines have revolutionized the way woodworkers create intricate designs and bring their ideas to life. These cutting-edge machines utilize computer numerical control (CNC) technology to automate and enhance the woodworking process, allowing for greater precision, efficiency, and customization options. In this introductory section, we will delve into the basics of CNC woodworking machines, defining the concept and highlighting their key components and functionality.

At its core, a CNC woodworking machine is a sophisticated tool that combines traditional woodworking techniques with modern automation. By utilizing computer programming and digital controls, these machines can execute complex movements with incredible accuracy. Whether it’s carving ornate patterns or producing intricate joints, CNC woodworking machines offer unparalleled precision that is difficult to achieve by hand.

The key components of a CNC woodworking machine include a control panel, motors, drives, spindles or routing heads – depending on the specific type of machine – and cutting tools. The control panel allows users to program the desired design and select parameters such as cutting speed and depth.

The motors and drives work together to move the cutting tools along multiple axes in precise increments. Finally, the cutting tools themselves range from drill bits to router bits or lasers, depending on the desired outcome.

With their ability to combine creativity with precision, CNC woodworking machines have transformed the field of woodworking. Craftsmen can now push boundaries once thought impossible by using advanced software programs to design intricate patterns or replicate complex shapes effortlessly. Throughout this article, we will explore not only how CNC technology has evolved from traditional methods but also its impact on design freedom, efficiency, and overall quality in woodworking projects.

The Evolution of Woodworking

Tracing the History and Development of CNC Woodworking Machines

Woodworking has a long and rich history, dating back to ancient civilizations. Traditional woodworking methods involve using hand tools and manual labor to shape and craft wood into various objects. While these techniques have been mastered over centuries, the introduction of computer numerical control (CNC) technology has revolutionized the woodworking industry.

CNC woodworking machines have their roots in the broader field of Computer Numerical Control, which emerged in the mid-20th century. Originally developed for metalworking industries, CNC technology quickly found its place in woodworking as well. In the 1970s, computer-controlled routers were introduced and marked a significant turning point in the evolution of woodworking methods.

Comparing the Advantages and Disadvantages of Traditional and CNC Woodworking Techniques

The adoption of CNC technology in woodworking brought about numerous advantages over traditional methods. One key advantage is precision. With CNC machines, woodworkers can achieve intricate cuts, complex shapes, and precise measurements that would be difficult to replicate with manual techniques. This precision also leads to increased efficiency since CNC machines can produce multiple identical pieces in a fraction of the time it would take manually.

Additionally, CNC woodworking machines offer greater flexibility and design freedom. These machines are capable of executing complex patterns or designs that would be challenging or impossible for human hands alone. From intricate carvings to three-dimensional sculptures, a wide range of artistic possibilities open up with CNC technology.

However, there are also some drawbacks associated with CNC woodworking methods. One notable disadvantage is the initial investment required to acquire a CNC machine. These machines can be costly compared to traditional hand tools or power tools used in woodworking. Furthermore, operating a CNC machine requires technical knowledge and expertise in programming. Woodworkers must learn how to operate specialized software programs that control the machine’s movements accurately.

Despite these drawbacks, many woodworkers have embraced CNC technology due to its undeniable benefits. The precision, efficiency, and design freedom offered by CNC woodworking machines have transformed the woodworking industry and opened up new horizons for craftsmen and artists alike. As technology continues to advance, the integration of CNC technology into woodworking will undoubtedly become more prevalent and further shape the future of woodworking methods.

Understanding the Inner Workings of CNC Woodworking Machines

In order to fully appreciate the capabilities and potential of CNC woodworking machines, it is important to understand their inner workings. At the heart of every CNC woodworking machine is computer numerical control, or CNC, which plays a crucial role in automating and controlling the entire woodworking process.

CNC technology allows woodworkers to precisely control and manipulate the movements of the machine through a series of numerical codes. These codes are created using specialized software, which translates design files into instructions that the machine can understand. The software calculates the exact dimensions, angles, and tool paths required to bring a digital design to life.

The mechanics behind CNC woodworking machines are equally important. The machines consist of several key components that work together to execute each task with precision and accuracy. These components include motors, lead screws or belts, spindle or router heads, cutting tools, and a workpiece-holding system.

Motors drive linear motion along different axes (typically X, Y, and Z), allowing for intricate cuts and shapes to be made on the wood surface. The spindle or router head holds various cutting tools such as bits or blades, which are selected based on the desired outcome. To ensure proper alignment and stability during operation, a sturdy workpiece-holding system is also incorporated.

By understanding these inner workings, woodworkers can harness the power of CNC technology more effectively. They can optimize their designs for efficient machining by considering factors such as tool choices and feed rates. Additionally, having knowledge about troubleshooting common problems with CNC woodworking machines can save time and materials in case any issues arise during operation.

Types of CNC Woodworking Machines and Their Applications

CNC woodworking machines come in various types, each designed for specific applications and tasks. Understanding the different varieties of CNC woodworking machines can help woodworkers choose the right tool for their projects and achieve optimal results. In this section, we will explore some of the common types of CNC woodworking machines and their applications.

CNC Routers

CNC routers are one of the most popular CNC woodworking machines available today. These machines use a rotating cutting tool to carve intricate designs into wood, creating beautiful patterns and shapes. CNC routers are versatile and can be used for a wide range of woodworking projects, such as cutting, shaping, engraving, and milling wood.

They are especially well-suited for creating detailed cabinetry, decorative moldings, signs, furniture components, and architectural elements. With the ability to work on large pieces of material and offer high precision cuts, CNC routers have become an essential tool for many woodworkers.

CNC Mills

CNC mills are another type of CNC woodworking machine commonly used in the industry. These machines utilize rotary cutters to remove material from a workpiece in order to create a desired shape or form. CNC mills excel at producing three-dimensional objects with complex designs and contours. They are ideal for fabricating furniture components that require precise shaping and machining processes. CNC mills can also be used to create joinery details like mortises and tenons with accuracy and consistency.

CNC Lathes

CNC lathes differ from routers and mills as they primarily focus on spinning a workpiece while cutting tools move along it with precision. This rotation enables the creation of symmetric cylindrical forms such as table legs, chair spindles, bowls, vases, or even baseball bats. One key advantage of using a CNC lathe is its ability to produce identical pieces in bulk quickly. The level of control provided by these machines allows woodworkers to achieve intricate designs and smooth, professional finishes.

By understanding the capabilities and applications of different types of CNC woodworking machines like routers, mills, and lathes, woodworkers can make informed decisions on which machine will best suit their needs. Whether it’s for intricate carvings, three-dimensional objects, or symmetric cylindrical forms, choosing the right type of CNC woodworking machine is crucial in achieving precise and high-quality results.

The Benefits of Using CNC Woodworking Machines

CNC woodworking machines offer several advantages over traditional woodworking techniques. These machines use computer numerical control (CNC) technology to automate and streamline the woodworking process, resulting in increased precision, efficiency, and speed. The impact of CNC technology on design freedom and quality in woodworking projects is also significant.

One of the main benefits of using CNC woodworking machines is their ability to produce precise and consistent results. These machines are programmed to follow specific instructions, ensuring that each cut, carve, or shape is executed with utmost accuracy. With traditional methods, human error can often lead to inconsistencies in measurements and angles, resulting in flawed pieces. CNC machines eliminate this issue by relying on computerized instructions that are executed flawlessly every time.

In addition to precision, CNC woodworking machines also offer enhanced efficiency and speed. These machines are capable of performing complex tasks at a much faster rate than human hands, significantly reducing production time. This increased efficiency allows woodworkers to take on larger projects or complete multiple pieces within a shorter timeframe.

| Advantages | Description |

|---|---|

| Precision | CNC woodworking machines offer precise and consistent results due to their programmed instructions. |

| Efficiency | CNC machines perform tasks at a faster rate than humans, resulting in reduced production time. |

| Speed | CNC woodworking machines can complete complex tasks quickly, allowing for increased productivity. |

Moreover, the integration of CNC technology in woodworking opens up new possibilities for design freedom and customization. Traditional methods often have limitations when it comes to intricate designs or complex shapes. CNC woodworking machines, on the other hand, can easily reproduce elaborate patterns and detailed designs that would be challenging to achieve manually. This flexibility allows woodworkers to unleash their creativity and produce unique, personalized pieces.

Getting Started with CNC Woodworking Machines

Getting started with CNC woodworking machines can be an exciting and rewarding experience for beginners. However, it is important to approach this new technology with the right knowledge and guidance to ensure a successful woodworking journey. In this section, we will provide step-by-step tips for beginners on how to use CNC woodworking machines effectively and safely.

Step 1: Familiarize Yourself with the Machine

Before using a CNC woodworking machine, it is essential to familiarize yourself with its components and functions. Take time to read the user manual provided by the manufacturer, as it will contain valuable information about the machine’s capabilities and safety guidelines. Additionally, consider watching video tutorials or attending workshops that demonstrate how to operate the specific model you are using. Understanding the basics of your machine will help you make full use of its potential.

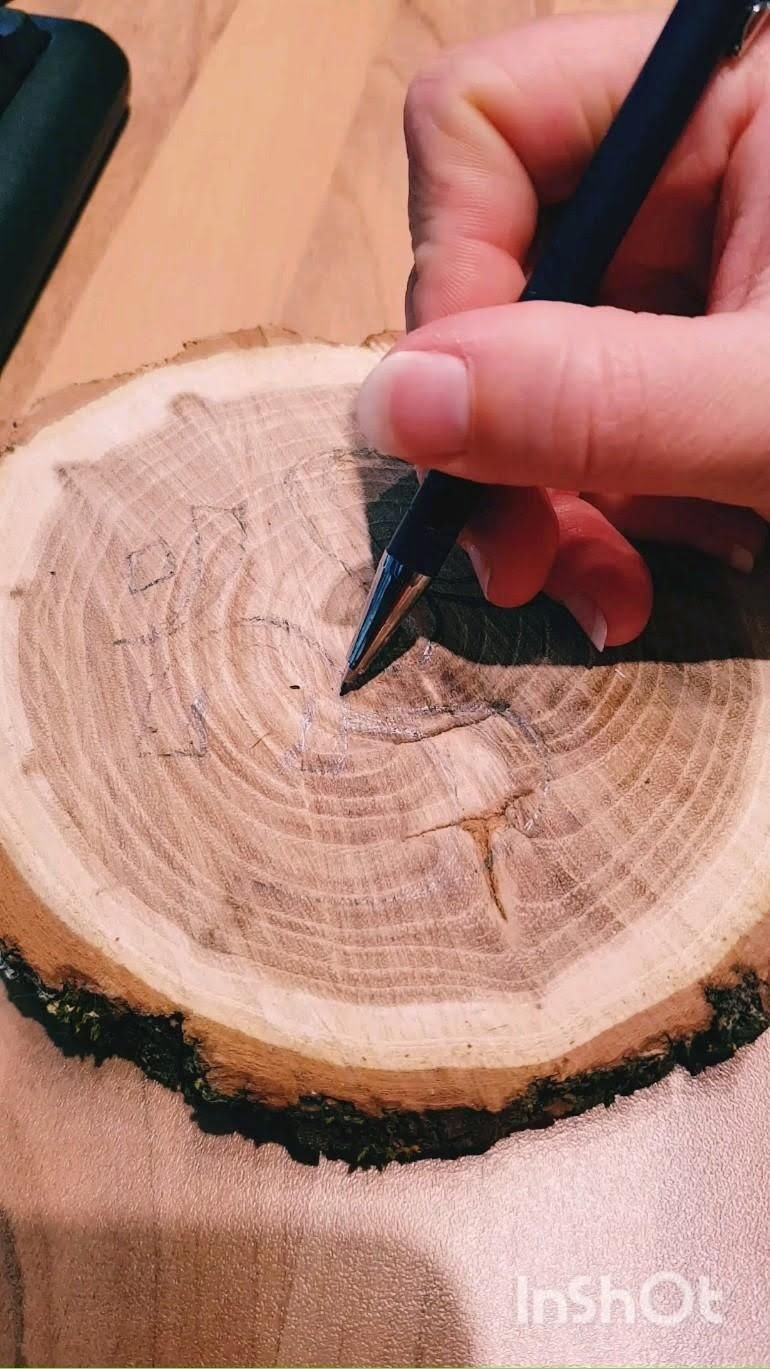

Step 2: Prepare Your Design

Designing your project is a crucial step in CNC woodworking. Start by creating a digital file using computer-aided design (CAD) software. This software allows you to draw precise measurements and shapes, which can then be translated into instructions for the CNC machine. Make sure your design is accurate and well-planned before proceeding to the next step.

Step 3: Set Up Your Material

Once you have a design ready, it’s time to prepare your material for machining. Choose high-quality wood that suits your project requirements and dimensions. Measure and cut your material according to the specifications outlined in your design file. It’s important to secure your material tightly onto the table or bed of the CNC machine using clamps or specialized fixtures. This will prevent any unnecessary movement during machining.

Step 4: Configure Cutting Parameters

To ensure precise and efficient cutting, you need to configure cutting parameters such as spindle speed, feed rate, depth of cut, and toolpath strategy in the CNC software. These parameters can vary depending on the type of wood, tooling, and design complexity. Consult the machine’s user manual or seek advice from experienced woodworkers to determine the optimal settings for your project.

Step 5: Run a Test Cut

Before running a full-scale cut on your material, it is recommended to perform a test run on a scrap piece of wood. This will help you verify that your machine is properly configured and that your design is accurately translated into machining instructions. Carefully observe the results and make any necessary adjustments to achieve the desired outcome.

By following these steps, beginners can confidently start their journey with CNC woodworking machines. Remember to prioritize safety at all times by wearing appropriate safety gear, maintaining a clean workspace, and regularly inspecting the machine for any signs of wear or damage. With practice and experience, you will unlock endless possibilities for creativity with CNC woodworking technology.

Inspiring Examples of CNC Woodworking Projects

Woodworking has always been a craft that requires skill, patience, and precision. However, with the introduction of CNC woodworking machines, craftsmen and hobbyists can take their creations to a whole new level. These machines have revolutionized the industry, allowing for stunning and innovative woodworking projects that were once thought impossible. In this section, we will explore some inspiring examples of CNC woodworking projects that showcase the capabilities and creativity of these machines.

One example of a stunning CNC woodworking project is intricately carved wooden furniture. With the precise control provided by CNC machines, craftsmen can create intricate patterns and designs on furniture pieces that would be nearly impossible to achieve by hand. From intricately carved chair backs to ornate tabletops, CNC woodworking machines allow for a level of detail and craftsmanship that is truly awe-inspiring.

Another example of the capabilities of CNC woodworking machines is in the creation of artistic wooden sculptures. Artists can use these machines to bring their visions to life, creating intricate statues and figures out of wood. The precision and accuracy provided by CNC technology ensure that every detail is perfectly replicated in the final product. These sculptures can range from realistic human figures to abstract forms, showing just how versatile CNC woodworking machines can be in the world of art.

Additionally, CNC woodworking machines are also used in architectural applications. Detailed wall panels, ornate ceiling medallions, and intricate door frames are just a few examples of what can be achieved with these machines. Whether it’s replicating historical designs or creating modern masterpieces, architects and designers can leverage the power of CNC technology to push boundaries and create unique architectural elements.

Overall, these inspiring examples highlight the endless possibilities offered by CNC woodworking machines. From furniture to sculptures to architectural elements, these machines allow for unparalleled precision and creativity in woodworking projects. By embracing this technology, craftsmen and hobbyists alike can unlock their full artistic potential and bring their visions to life in ways they never thought possible.

The Future of CNC Woodworking Machines

As technology advances at a rapid pace, the future of CNC woodworking machines is filled with exciting trends and innovations. Woodworkers and designers can look forward to new developments that will enhance their creativity, efficiency, and precision. This section will explore some of the emerging trends in CNC woodworking technology and the innovative advancements that are on the horizon.

One major trend in the future of CNC woodworking machines is the integration of artificial intelligence (AI) and automation. AI has the potential to revolutionize woodwork by enabling machines to analyze designs, make decisions, and execute tasks with minimal human intervention.

By using machine learning algorithms, CNC woodworking machines can adapt to different project requirements, optimize tool paths, and improve overall productivity. This level of automation not only saves time but also reduces errors, ensuring consistent quality in each woodworking project.

In addition to AI integration, another prominent trend in CNC woodworking machines is the use of robotics. Robotics allows for increased efficiency and precision by automating complex tasks such as carving intricate patterns or sculpting three-dimensional objects.

Robots equipped with advanced sensors can detect changes in material density, grain direction, or surface irregularities in real-time, making adjustments as needed for optimal results. With robotics, woodworkers can achieve intricate details and complex designs that would be challenging or time-consuming to accomplish by hand.

Advancements in software are also shaping the future of CNC woodworking machines. Improved CAD/CAM software offers more intuitive user interfaces, allowing woodworkers to design intricate projects quickly and easily translate them into machine-readable code. Furthermore, software developments enable greater connectivity between various tools and machines within a workshop setup. For example, designers can seamlessly transfer their design files from their computer directly to a CNC router or mill without any compatibility issues or manual data entry.

| Trend | Innovation |

|---|---|

| Integration of artificial intelligence (AI) and automation | Machine learning algorithms for optimized tool paths and increased productivity |

| Use of robotics | Sensors for real-time adjustments and automated complex tasks |

| Advancements in software | Improved CAD/CAM software for intuitive design and seamless transfer of files |

The future of CNC woodworking machines holds immense potential, revolutionizing the way woodworkers bring their creative visions to life. With the integration of AI, automation, robotics, and advanced software, these machines will continue to evolve and empower artisans to push the boundaries of what is possible with wood. Woodworkers who embrace these trends and innovations will gain a competitive edge in the industry while enjoying enhanced efficiency, precision, and artistry in their craft.

Conclusion

In conclusion, CNC woodworking machines have revolutionized the woodworking industry by providing a new level of precision, efficiency, and speed. The key takeaways from this article include understanding the basics of CNC woodworking machines, exploring their evolution from traditional methods, and delving into their inner workings. Additionally, we have examined the different types of CNC woodworking machines and their applications, as well as the benefits they offer in terms of design freedom and quality.

It is clear that embracing CNC technology can unlock limitless creativity for woodworkers. By utilizing computer numerical control and the advanced mechanics and software behind CNC woodworking machines, craftsmen can expand their capabilities and achieve intricate designs that were previously difficult or impossible to create. Moreover, with the diverse range of CNC woodworking machine types available, woodworkers can customize their processes to suit their specific needs and preferences.

Moving forward, it is important for woodworkers, both experienced professionals and hobbyists alike, to embrace the use of CNC woodworking machines. These innovative tools not only enhance efficiency but also allow for greater artistic expression. As technology continues to advance, we can expect exciting trends and innovations in CNC woodworking machines such as the integration of artificial intelligence and automation.

By staying updated with these advancements and constantly improving our skills with these tools, we can truly unlock limitless creativity in our woodworking projects. So why wait? Embrace CNC technology today and take your craft to new heights.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.