Woodworking templates are essential tools that help woodworkers achieve accuracy, precision, and consistency in their projects. A template, in the context of woodworking, is a pattern or guide used to replicate shapes, curves, cutouts, and other design elements onto a workpiece. It serves as a template for the final piece being crafted.

Templates play a crucial role in various woodworking projects, from simple tasks like creating rounded corners to more intricate endeavors such as complex joinery and detailed carvings. They provide a foundation for achieving desired outcomes by guiding the woodworker through each step of the process.

Using templates not only enhances the precision but also improves efficiency in woodworking. By utilizing templates, woodworkers can save time by eliminating the need to measure and mark every individual piece repeatedly. Templates enable consistent replication, reducing human errors and ensuring that each component of the project matches perfectly.

Whether you are a beginner or an experienced woodworker, understanding the basics of woodworking templates is vital for achieving professional-level results. In the following sections of this article, we will delve deeper into exploring their purpose, types, design process, applications, advantages as well as limitations.

Additionally, we will discuss how to properly care for and maintain woodworking templates to ensure their longevity. So let’s dive into the world of woodworking templates and learn how they can take your craftmanship to new heights.

The Purpose of Using Templates

Templates are an essential tool in woodworking as they serve to enhance precision and efficiency in various woodworking projects. By using templates, woodworkers can achieve accuracy and improve the overall quality of their creations. Templates also save time and reduce errors by allowing for consistent replication.

One of the primary purposes of using templates in woodworking is to ensure precise measurements and shapes. Templates act as a guide for cutting or shaping the wood, providing a consistent template to follow. This helps in achieving uniformity across multiple pieces of work, such as making identical chair legs or table legs. With templates, woodworkers can easily trace or mark the desired shape onto the workpiece, eliminating guesswork and ensuring accuracy.

Furthermore, templates aid in enhancing efficiency by reducing manual measurements and repetitive tasks. Instead of measuring multiple times for each piece, woodworkers can simply use the template to mark or cut identical shapes quickly. This not only saves time but also reduces the chances of measurement errors that could result from repetitive measuring.

In addition to precision and efficiency, templates also allow woodworkers to experiment with complex designs more easily. With intricate patterns or curves, templates provide a reliable guide for accurately replicating these designs on multiple pieces. For example, when creating decorative trim or intricate carvings, using a template ensures consistency throughout the project.

Overall, templates play a crucial role in both basic and advanced woodworking projects by enhancing precision and efficiency. They not only help achieve accurate measurements and shapes but also save time by allowing for consistent replication. Whether it’s simple shapes or complex designs, utilizing templates can greatly improve the quality of woodworking outcomes.

| Advantages | Limitations |

|---|---|

| – Enhance precision | – Limited versatility for unique designs |

| – Improve efficiency by reducing manual measurements | – Potential for limitations in size and intricate details |

| – Enable consistent replication of shapes | – Requires initial investment of time and effort to create templates |

Types of Woodworking Templates

Woodworking templates come in various types and complexity levels, each serving a specific function in the woodworking process. Understanding these different types of templates is essential for woodworkers to effectively utilize them in their projects. From basic shape templates to more complex jigs and patterns, here are some commonly used woodworking templates:

1. Shape Templates:

Shape templates are perhaps the most basic type of woodworking template. They are typically made from sturdy materials such as plywood or acrylic, and they serve as guides for shaping the workpiece. Shape templates can be simple, geometric outlines that allow woodworkers to trace or cut along the edges to achieve consistent shapes.

2. Jigs:

Jigs are another commonly used type of woodworking template that helps with repetitive tasks or specific operations. They often consist of multiple pieces designed to hold a workpiece securely and guide tools during cutting, drilling, or routing. For example, a dado jig may be used to ensure precise and consistent dado cuts across multiple pieces of wood.

3. Patterns:

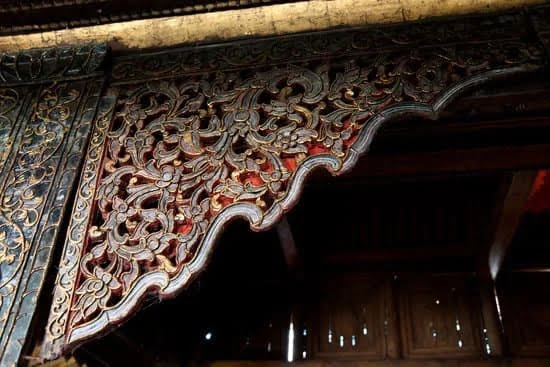

Patterns are templates specifically used for creating intricate designs or decorative elements on woodwork. They can be either physical or digital representations of the desired design that guide woodworkers during carving or routing processes. Patterns can range from simple motifs to highly detailed designs, allowing woodworkers to add visually appealing elements to their projects.

Each type of woodworking template serves a unique purpose in enhancing precision and efficiency in woodworking projects. By utilizing these templates appropriately, woodworkers can achieve consistent results while saving time and reducing errors through replication.

| Type | Function | Example Application |

|---|---|---|

| Shape Templates | Guides for shaping workpieces | Cutting out consistent curved edges for chair backs |

| Jigs | Guides tools for specific operations | Routing precise mortise and tenon joints |

| Patterns | Aids in creating intricate designs | Carving detailed floral motifs on cabinet doors |

Woodworking templates serve as invaluable tools for woodworkers of all skill levels, enabling them to achieve high levels of precision and efficiency in their projects. By understanding the different types of templates available and their respective applications, woodworkers can harness the full potential of these tools to elevate the quality of their woodworking endeavors.

Designing and Creating Woodworking Templates

Designing and creating woodworking templates is a crucial step in any woodworking project. These templates serve as guides and aids in achieving accurate and precise results. By following a step-by-step process, woodworkers can design and fabricate templates that are specific to their desired project.

To begin the process of designing a woodworking template, it is important to have a clear vision of the final product. Take into consideration the dimensions, shape, and intricacies of the workpiece. Once this vision is established, it’s time to select suitable materials for the template. Materials such as plywood or acrylic sheets are commonly used due to their durability and ease of shaping.

Next, it is essential to gather the necessary tools for template creation. Tools like a jigsaw or bandsaw can be used to cut out the shape of the template from the chosen material. Additionally, other tools like sandpaper or a router may be needed for refining the edges and smoothing out any imperfections.

Once the template has been cut out, it should be carefully matched against the workpiece to ensure accuracy. It is advisable to make any adjustments or refinements at this stage before proceeding with further steps in the woodworking process.

Understanding the Template-Workpiece Relationship

Templates in woodworking are not just standalone tools; they have a direct and intimate relationship with the workpiece. Understanding this template-workpiece relationship is crucial for achieving accurate and precise results in woodworking projects.

One key aspect of this relationship is proper alignment. When using templates, it is important to ensure that they are aligned correctly with the workpiece. This involves properly positioning the template on the surface of the workpiece and securing it in place. By doing so, woodworkers can ensure that the desired shape or pattern is accurately transferred onto the workpiece.

Another important aspect of the template-workpiece relationship is secure placement. Templates need to be securely attached to prevent any movement or shifting during the woodworking process. This can be achieved through various methods such as clamps, double-sided tape, or even screws for larger templates. Secure placement ensures that the template remains firmly in position throughout the cutting, shaping, or routing process, resulting in consistent and precise outcomes.

To further enhance accuracy and precision, woodworkers may also use guide bushings or bearing-guided bits when following a template. These additional tools help maintain a consistent distance between the router bit or saw blade and the template, reducing any potential errors caused by human variability.

Examples of Template Usage in Woodworking Projects

Templates are invaluable tools in woodworking projects, offering precision, efficiency, and consistency. They are used for a wide range of applications, from creating curved edges to routing patterns and precise cutouts. Let’s explore some specific examples of how templates are utilized in woodworking projects.

1. Creating Curved Edges:

One common use of templates in woodworking is for creating curved edges on furniture or decorative items. A shape template is used to transfer the desired curve onto the workpiece, allowing the woodworker to trace and then cut along the outline. This ensures that each piece created has the same curvature, resulting in a consistent and visually pleasing end product.

2. Routing Patterns:

Templates also come into play when routing intricate patterns onto wood surfaces. For example, if a woodworker wants to create intricate designs on a table leg or cabinet door, they can design a pattern template that fits securely onto the workpiece. By using this template with a router and following its contours, the desired pattern is replicated effortlessly and with precision.

3. Precise Cutouts:

Templates are especially useful when it comes to making precise cutouts in wood pieces for fittings such as door hinges or electrical outlets. A template serves as a guide for marking the exact position on the workpiece where the cutout needs to be made. The woodworker can then use saws or routers to accurately remove material within the marked area.

In all these examples, utilizing templates guarantees consistent results throughout the woodworking project while minimizing errors and improving efficiency. Woodworkers can experiment with different shapes, patterns, and designs by simply using various templates tailored to their project needs.

Advantages and Limitations of Using Templates in Woodworking

Advantages of Using Templates in Woodworking

Using templates in woodworking projects offers several advantages that can greatly benefit both beginners and experienced woodworkers.

- Precision and Accuracy: One of the main advantages of using templates is that they help achieve precise and accurate results. Templates act as guides, ensuring that each piece is cut or shaped according to the desired dimensions or design. They eliminate guesswork and provide a consistent reference point throughout the project. By following the template, woodworkers can create highly detailed and symmetrical components, resulting in a professional-looking finished product.

- Efficiency and Time Savings: Templates also contribute to increased efficiency in woodworking projects. Once a template is created, it can be reused multiple times, saving time on measuring and marking for each individual piece. This consistency not only speeds up production but also reduces errors that may occur during manual measurements. Woodworkers can focus more on executing the actual construction or finishing techniques while relying on the template for accurate sizing and shaping.

- Replication and Consistency: Another advantage of templates is their ability to ensure consistency when replicating a design or pattern across multiple pieces. Whether it’s creating identical cabinet doors or producing multiple carved decorations, templates allow woodworkers to accurately recreate the same shape or pattern every time. This consistency is essential for maintaining a cohesive look in furniture sets or achieving uniformity in decorative elements.

Limitations of Using Templates in Woodworking

While templates offer many benefits, they do have some limitations that woodworkers should be aware of.

- Design Constraints: Templates are designed for specific shapes or patterns, which means they may not be suitable for every woodworking project. If an intricate or unique design requires significant variations from a standard template, it might be challenging to find an appropriate template or create one from scratch.

- Limited Flexibility: Some woodworking projects may involve customization or adjustments during construction based on specific requirements or creative choices. In such cases, using pre-made templates may limit the woodworker’s ability to deviate from the pre-determined design. Templates work best for projects that require precise replication and do not need significant alterations.

- Size Limitations: Templates can be limited in size due to practical considerations. For larger or oversized pieces, creating a template becomes more complex and cumbersome. Woodworkers may need to combine multiple templates or use alternative methods such as scaling up a smaller template. It is important to consider the size limitations of templates when planning projects that involve large-scale components.

Despite these limitations, utilizing templates remains an invaluable practice in woodworking due to their contribution to accuracy, efficiency, and consistency in achieving desired results. By understanding their advantages and limitations, woodworkers can effectively incorporate templates into their projects while making informed decisions about when and how to best utilize them.

Care and Maintenance of Woodworking Templates

Woodworking templates are valuable tools that can enhance precision and efficiency in woodworking projects. To ensure the longevity and usability of these templates, proper care and maintenance is crucial. Taking good care of woodworking templates not only helps extend their lifespan but also ensures accurate and consistent results in future projects. Here are some important tips to consider when it comes to caring for and maintaining woodworking templates:

Proper cleaning

After each use, it is important to clean your woodworking template to remove any dust, debris, or residue that may have accumulated. Depending on the material of your template, you can use various cleaning methods such as wiping with a damp cloth, using mild soap and water, or using a specialized cleaning solution. It is important to avoid abrasive cleaners or harsh chemicals that could damage the template.

Storage

When not in use, it is essential to store your woodworking templates properly to protect them from potential damage. Consider storing them in a dry and cool environment away from direct sunlight or extreme temperatures. Additionally, you may want to invest in protective cases or sleeves specifically designed for storing templates. These cases will help prevent scratches, dents, or other physical damage.

Preservation techniques

To further preserve the quality of your woodworking templates, you can apply a protective coating on the surface. This coating can be a clear varnish or a specific sealer depending on the material of the template. The protective coating not only adds an extra layer of defense against wear and tear but also allows for easier cleaning by preventing adhesion of dust and debris.

Caring for and maintaining your woodworking templates is an essential part of ensuring their long-term usability. By following these simple tips for proper cleaning, storage, and preservation techniques, you can keep your templates in good condition for years to come. Remember that well-maintained templates will continue to provide accurate replication of designs and contribute to the success of your woodworking projects.

Conclusion

In conclusion, woodwork templates are essential tools that greatly contribute to the success and precision of woodworking projects. By defining what a template is and discussing its importance and versatility, we have gained an understanding of how templates can enhance our woodworking outcomes.

Throughout this article, we explored the purpose of using templates, the different types commonly used, and the process of designing and creating them. Additionally, we highlighted the significance of ensuring proper alignment and secure placement when utilizing templates in woodworking.

Templates play a crucial role in achieving accuracy and improving the quality of woodworking projects. They save time by allowing consistent replication and reduce errors that may occur when working freehand. Whether it’s shape templates for creating curved edges or patterns for routing intricate designs, templates provide a guide for precise cutouts and accurate measurements.

While there are undeniable advantages to using templates in woodworking, it is important to acknowledge their limitations as well. Woodworkers may need to invest time in designing and crafting specific templates for each project, which can be a challenge if working on complex or unique designs. Additionally, care must be taken in maintaining these tools through proper cleaning, storage, and preservation techniques to ensure their longevity.

Frequently Asked Questions

What is template in woodworking?

In woodworking, a template refers to a pattern or guide that is used to replicate a specific shape or design. It is typically made from a sturdy material such as wood, metal, or plastic and acts as a reference for achieving accurate and consistent results.

Templates can be created for various woodworking projects, including cutting intricate shapes, drilling holes in precise locations, or carving intricate details. By using a template, woodworkers can minimize errors and produce multiple identical pieces efficiently.

What’s the difference between a jig and a template?

While similar in concept, there is a subtle difference between a jig and a template in woodworking. A jig is primarily used to assist in controlling the movement of tools during the construction process. It often includes additional components such as clamps or guides that secure the workpiece and ensure accurate positioning while performing specific operations like cutting, drilling, or shaping.

On the other hand, a template focuses more on providing an outline or shape to guide the creation of multiple identical pieces. Templates are typically fixed guides that don’t involve manipulating tools directly but rather serve as references for achieving consistent results.

What is the purpose of a template?

The purpose of a template in woodworking serves several important functions. Firstly, templates allow woodworkers to create precise and uniform shapes across multiple pieces without having to measure each one individually. This saves both time and effort while ensuring consistency throughout the project.

Templates also help minimize errors by acting as visual guides to follow while working with tools or performing tasks like routing or carving delicate details. They provide stability and support for accurately positioning workpieces during operations, reducing the risk of mistakes or misalignment. Ultimately, templates enhance efficiency and accuracy in woodworking by providing reliable references for shaping and creating complex designs.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.