Woodworking technology has come a long way, transforming the ancient craft into a modern marvel of precision and efficiency. In this blog post, we will delve into the world of woodworking technology, uncovering its growing significance and exploring the curiosity it sparks in readers.

From understanding the basics and evolution of woodworking technology to embracing cutting-edge tools, CNC machines, automated processes, software integration, environmental considerations, and future possibilities – we will uncover all aspects of this fascinating industry. Whether you’re a seasoned woodworker or someone simply intrigued by the wonders of modern innovation, join us on this journey as we explore the extraordinary world of woodworking technology.

Woodworking technology is more than just using traditional tools; it encompasses a wide range of advancements that have revolutionized the industry. Understanding its basics involves not only defining woodworking technology but also tracing its evolution throughout history. By exploring its pivotal role in shaping the woodworking industry, we can truly appreciate the transformative power it holds.

One aspect that showcases the growth and progress in woodworking technology is the development and integration of different tools. While traditional tools still hold their charm and purpose in woodworking projects, they now coexist with innovative inventions brought by technological advancements. These cutting-edge tools not only enhance efficiency but also offer unparalleled precision. The marriage of traditional craftsmanship with modern techniques presents endless possibilities for woodworkers to express their creativity while achieving remarkable results.

Join us as we continue our exploration into various facets of woodworking technology. From examining CNC machines that have revolutionized precision and efficiency to discussing automated processes that streamline production and enhance quality control, our journey into this realm promises to be enlightening. Together, let’s embrace the ever-evolving world of woodworking technology and unlock new dimensions of creativity and precision in our projects.

Understanding the Basics

Woodworking technology has come a long way since its inception. To fully grasp the significance of this field, it is crucial to understand the basics of woodworking technology and how it has evolved over time. Woodworking technology can be defined as the use of machinery, tools, and software to enhance efficiency, precision, and creativity in woodworking projects.

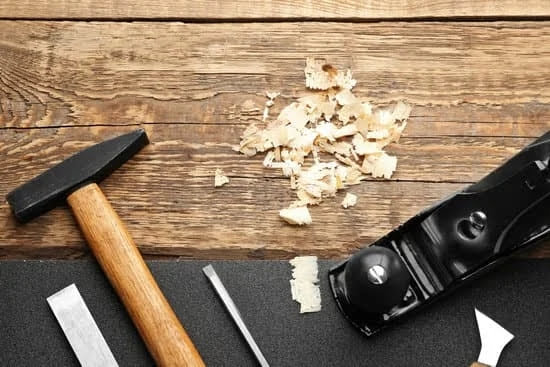

Historically, woodworking was carried out using hand tools such as saws, chisels, and planes. While these traditional tools are still used today by some craftsmen who appreciate the artistry and skill required in their use, modern woodworking technology has introduced a wide range of cutting-edge tools that have revolutionized the industry. This evolution has allowed for more efficient production methods and greater precision in creating intricate designs.

One example of this evolution is the introduction of power tools such as electric saws, drills, routers, and sanders. These tools greatly enhance productivity by reducing the time and effort needed to complete woodworking tasks. Additionally, they offer increased precision through features like laser guides or digital displays that ensure accurate measurements and cuts.

Moreover, advancements in woodworking technology have also led to the development of computer numerical control (CNC) machines. These machines are programmed with precise instructions to perform various woodworking tasks automatically. They offer unparalleled precision and consistency in producing complex shapes and designs that would otherwise be challenging or time-consuming using traditional methods.

Overall, understanding the basics of woodworking technology helps us appreciate its profound impact on shaping the woodworking industry. By embracing modern tools and techniques brought by woodworking technology, craftsmen can achieve higher levels of efficiency, precision, and creativity in their projects than ever before.

Woodworking Tools

Woodworking has a long history that dates back thousands of years, and the tools used in this craft have evolved tremendously over time. Traditional woodworking tools were often simple hand tools that required skill and precision to create intricate designs. However, with the advent of woodworking technology, the industry has witnessed a revolution in terms of efficiency and precision.

Traditionally, woodworking involved using basic tools such as saws, chisels, planes, and hammers. These tools required a high level of craftsmanship and physical strength to manipulate the wood into desired shapes and forms. While these traditional tools are still used by some woodworkers today, modern woodworking technology has introduced revolutionary power tools that have significantly enhanced productivity and precision.

One of the groundbreaking contributions of woodworking technology is the introduction of power tools such as electric saws, drills, sanders, and routers. These power tools not only reduce manual labor but also enable woodworkers to accomplish tasks more quickly and accurately. Electric saws make cutting through wooden boards effortless while drills allow for precise hole drilling. Sanders ensure smooth finishes on surfaces, and routers bring versatility in shaping edges and patterns onto wooden pieces.

| Traditional Tool | Cutting-Edge Alternative |

|---|---|

| Hand Saw | Circular Saw or Miter Saw |

| Chisel | Wood Router with Chisel Bit |

| Hand Plane | Bench Planer or Thickness Planer |

These modern power tools not only save time but also allow for greater precision and accuracy in woodworking projects. Woodworkers can achieve cleaner cuts, smoother finishes, and intricate designs with the help of these advanced tools. As technology continues to advance, woodworkers can expect even more innovative tools that will further streamline their work processes and expand their creative possibilities.

CNC Machines in Woodworking

Woodworking technology has experienced significant advancements over time, with one of the most revolutionary developments being Computer Numerical Control (CNC) machines. These machines have completely transformed the woodworking industry by offering unparalleled precision and efficiency in various woodworking projects.

CNC machines are automated tools that use computer programming to control their movement and operations. They can perform a wide range of tasks with remarkable accuracy, including cutting, carving, drilling, and shaping wood. By eliminating the need for manual labor, CNC machines have drastically reduced the time required to complete woodworking projects while ensuring consistent and precise results.

One of the key advantages of using CNC machines in woodworking is their ability to replicate designs with high levels of accuracy. These machines can produce multiple identical parts without any variation, making them ideal for mass production or creating intricate and complex designs. Moreover, CNC machines allow woodworkers to execute intricate details that would be challenging or impossible to achieve manually.

In addition to precision, CNC machines also excel in terms of efficiency. They are capable of operating continuously for extended periods without fatigue or human error. This translates into increased productivity and shortened project completion times. Furthermore, CNC machines can optimize material usage by automatically arranging cuts on a board to minimize waste, thus reducing overall costs.

| Advantages | Data |

|---|---|

| Precision | Produces highly accurate and consistent results |

| Efficiency | Increases productivity and shortens project completion times |

| Complexity | Allows for the creation of intricate and complex designs |

| Material Optimization | Minimizes waste and reduces overall costs |

CNC machines have undoubtedly revolutionized the woodworking industry by offering unmatched precision, efficiency, and versatility. Woodworkers can now push the boundaries of their creativity while consistently achieving high-quality results. As technology continues to advance, it is likely that CNC machines will play an increasingly significant role in shaping the future of woodworking.

Automated Woodworking

Automated woodworking has emerged as a revolutionary trend that is transforming the woodworking industry. By utilizing advanced technology and machinery, automated woodworking processes are streamlining production and enhancing the overall quality of wooden products. This section will dive into the various aspects of automated woodworking, including the emerging trends, benefits, and real-life examples.

Examining Emerging Trends

In recent years, there has been a significant rise in the adoption of automation in woodworking processes. Automated machines and robots are being integrated into various stages of production, such as wood cutting, shaping, carving, and finishing. This trend is driven by the need for increased efficiency, accuracy, and productivity in woodworking operations. With automated systems in place, companies can achieve higher output levels while minimizing manual labor and human error.

Additionally, an increasing number of manufacturers are incorporating artificial intelligence (AI) and machine learning into their automated woodworking processes. These technologies allow machines to analyze data collected during production to optimize performance and make adjustments for better results. The ability of AI-powered systems to learn from experience helps improve precision and consistency in woodworking operations.

Discussing Benefits

The implementation of automated woodworking comes with several compelling advantages for both manufacturers and consumers. One key benefit is increased productivity. Automated machines can operate 24/7 without fatigue or breaks, resulting in higher production rates compared to traditional methods. This allows businesses to meet demand more efficiently while reducing costs associated with labor expenses.

Furthermore, automated woodworking enhances quality control by minimizing human errors. Consistency in measurements, cuts, and finishes leads to superior precision throughout the manufacturing process. Automated systems also enable manufacturers to produce customized wooden products with intricate designs that would otherwise be challenging or time-consuming using traditional methods.

Showcasing Real-Life Examples

There are numerous real-life examples highlighting how automated woodworking has transformed production processes in various industries. For instance, furniture manufacturers now use advanced robotic systems for tasks such as wood cutting, sanding, and assembling. These robots can precisely measure and cut wooden components with minimal waste and maximum accuracy, leading to faster production times and improved quality.

In the construction industry, automated woodworking is being utilized to fabricate pre-fabricated wooden modules and components for buildings. This approach allows for faster construction timelines, reduced on-site labor requirements, and enhanced precision in assembling structures. Additionally, automated woodworking has found applications in the crafting of musical instruments, where intricate designs and precise measurements are critical for optimal sound quality.

Overall, automated woodworking is redefining the possibilities within the industry by streamlining production processes and enhancing the quality of wooden products. As technology continues to evolve at a rapid pace, it is expected that automation will become even more prominent in woodworking operations, leading to increased efficiency and innovation in this age-old craft.

Woodworking Software and Design

Woodworking software and design have become indispensable tools in the modern woodworking industry, empowering professionals with unparalleled creativity and precision. With the integration of software, woodworkers can now translate their ideas into digital designs and optimize their workflow for maximum efficiency. This section will explore the role of software in woodworking design and planning, discuss various software options available for woodworking professionals, and highlight how the integration of software with woodworking technology has revolutionized creativity and precision.

In today’s digital age, woodworking software offers a wide range of functionalities that enable designers to bring their vision to life. From 3D modeling to virtual simulations, these powerful tools allow woodworkers to visualize their projects before bringing them to fruition. By being able to see a design in a virtual environment, woodworkers can make necessary adjustments and refinements without wasting time or material resources.

There are numerous software options available for woodworking professionals, each offering unique features tailored to specific needs. Design programs like SketchUp provide intuitive interfaces for creating 3D models, while CAD (Computer-Aided Design) software such as AutoCAD offers extensive capabilities for precise measurements and technical drawings. Additionally, there are also specialized woodworking CAD/CAM (Computer-Aided Manufacturing) programs like Vectric Aspire that blend design capabilities with toolpath generation for CNC machines.

The integration of software with woodworking technology has significantly enhanced both creativity and precision in the field. Woodworkers can experiment with different designs, materials, and finishes virtually before committing to physical production. Software-enabled precision ensures accurate measurements, placement of joints and hardware, and overall consistency throughout the project. Moreover, by generating toolpaths directly from the digital design files, woodworkers can achieve flawless execution on CNC machines, resulting in intricate details that were previously impossible or extremely time-consuming.

Overall, woodworking software has blossomed into an essential component of contemporary woodworking technology. It not only empowers woodworkers with advanced design capabilities but also allows them to streamline their workflow and achieve unparalleled precision. By embracing these software tools, woodworking professionals can unlock a world of creativity and take their craftsmanship to new heights.

Environmental Considerations

Woodworking technology has experienced significant advancements over the years, revolutionizing the industry and offering new opportunities for creativity and precision. However, it is crucial to consider the environmental impact of these innovations. In this section, we will explore sustainable practices in woodworking technology and discuss how professionals can embrace eco-friendly approaches.

Addressing the Environmental Impact

As woodworking technology continues to evolve, it is essential to examine its environmental footprint. Traditional woodworking processes often involve the use of harmful chemicals or unsustainable practices that contribute to deforestation and pollution. However, there are now more environmentally friendly alternatives available that promote sustainability in the industry.

Sustainable Practices and Materials

One key aspect of sustainable woodworking technology is the utilization of eco-friendly materials. Instead of relying solely on traditional wood sources, professionals can explore options such as reclaimed wood or certified sustainably harvested timber. These materials minimize deforestation and support responsible forestry practices.

Additionally, adopting energy-efficient practices in woodworking workshops can significantly reduce environmental impact. This includes using energy-saving tools and equipment, implementing efficient waste management systems for sawdust and scraps, and exploring renewable energy sources like solar power.

Encouraging Readers to Embrace Eco-Friendly Woodworking Practices

As readers explore and harness the power of woodworking technology, it is important to prioritize environmentally friendly approaches. By choosing eco-friendly materials, implementing energy-efficient practices, and staying informed about sustainability trends in the industry, individuals can make a positive difference in their woodworking endeavors while enjoying limitless possibilities for creative expression.

Future Possibilities

The field of woodworking technology is constantly evolving, and the future holds exciting prospects for this industry. As technology continues to advance at a rapid pace, the possibilities for woodworking are expanding in ways that were once unimaginable. From innovative tools and machines to cutting-edge software and design capabilities, there is no limit to what can be achieved with woodworking technology.

One of the most promising advancements in woodworking technology is the integration of artificial intelligence (AI). AI has the potential to revolutionize the way woodworking projects are planned, designed, and executed. With AI-powered algorithms, woodworkers can optimize material usage, identify potential flaws or weaknesses in a design, and even generate unique designs based on specific parameters. This will not only save time and resources but also open up new avenues for creativity that were previously unexplored.

Another area of growth in woodworking technology is wearable devices and augmented reality (AR). Wearable devices such as smart glasses or haptic gloves can enhance precision and safety during woodworking tasks. They can provide real-time guidance, measurements, and feedback to the user, ensuring accurate cuts and minimizing errors. AR technology allows woodworkers to visualize their designs in a three-dimensional space before making any physical cuts, enabling better planning and reducing waste.

In addition to these developments, robotics is set to play an increasingly significant role in woodworking technology. Robots equipped with advanced sensors and actuators can automate repetitive tasks such as sanding or assembling components, freeing up human workers to focus on more complex aspects of the project. This automation not only improves efficiency but also enhances quality control by reducing human error.

As we look ahead to the future of woodworking technology, it is clear that there are endless possibilities waiting to be explored. From AI-driven design software to wearable devices and robotics, these advancements have the potential to streamline production processes while enhancing creativity and precision.

Woodworking professionals would do well to stay informed about these emerging technologies and embrace them in order to stay ahead in this ever-evolving industry. By embracing the future of woodworking technology, we can unlock unparalleled possibilities for creativity and precision in our woodworking endeavors.

Conclusion

In conclusion, woodworking technology has truly revolutionized the art and industry of woodworking. Throughout this blog post, we have explored the evolution of woodworking technology, from its humble beginnings to the cutting-edge tools and techniques used today. We have seen how traditional woodworking tools have been enhanced and improved upon by modern advancements, leading to unprecedented levels of efficiency and precision.

One of the most significant advancements in woodworking technology is the introduction of CNC machines. These computer-controlled machines have revolutionized the way woodworking projects are executed, allowing for unparalleled precision and efficiency. The integration of automation in woodworking processes has also streamlined production and enhanced quality control, offering a glimpse into a future where woodworkers can achieve even greater heights.

Furthermore, the integration of software with woodworking technology has empowered creativity and precision. Woodworking professionals now have access to a wide range of software options that aid in design and planning, allowing for intricate and precise creations. This fusion of software and woodworking technology has opened up endless possibilities for innovation and craftsmanship.

As we move forward into the future, it is important for woodworkers to embrace these technological advancements and stay informed about emerging technologies that will shape the industry. By leveraging the power of woodworking technology, craftsmen can unlock unparalleled levels of creativity and precision in their work. So let us embark on this journey together, exploring new possibilities, embracing sustainable practices, and pushing the boundaries of what is possible in woodworking.

Frequently Asked Questions

What are the examples of woodworking?

Woodworking refers to a wide range of activities that involve working with wood. Examples of woodworking include carpentry, which focuses on building structures like houses, cabinets, and furniture using various woodworking tools.

Woodturning is another example where skilled artisans use a lathe to shape wood into decorative objects like bowls and sculptures. Additionally, woodworking encompasses carving, joinery, and cabinet making, where intricate details are crafted by hand to create functional or artistic wooden pieces.

How has Technology affected woodworking?

Technology has significantly impacted the practice of woodworking in various ways. One of the notable impacts is the introduction of power tools, such as electric saws, planers, routers, and sanders. These advancements have made tasks quicker and more efficient compared to traditional hand tools alone.

Computer-aided design (CAD) software has also revolutionized the industry by allowing woodworkers to create detailed plans and prototypes before starting a project. Furthermore, advancements in woodworking machinery have enabled mass production and improved precision in manufacturing wooden furniture and other products.

What is the woodworking industry called?

The woodworking industry is commonly referred to as the “woodworking trade” or simply “woodworking.” It encompasses all businesses involved in crafting wooden products for commercial or personal use. This can include small-scale workshops operated by individual craftsmen or larger industrial facilities that produce furniture on a mass scale.

In recent years, there has been a surge in interest among hobbyists who engage in woodworking as a recreational pursuit or even turn it into a small business venture. The woodworking industry covers everything from millwork and cabinetry to custom furniture-making and architectural woodworking projects.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.