Compare Woodworker II Sharpening System to Other Sharpening Methods

The Woodworker II Sharpening System is an all-in-one tool designed to keep your cutting and carving tools sharp. It uses a combination of precision machined guides, diamond stones and water to quickly, easily and safely sharpen any type of edge. This system is perfect for professionals in the woodworking trades where maximum edge performance is required. Compared to traditional sharpening methods such as stones, files or grinding wheels, Woodworker II’s method offers more control over the level of sharpness achieved, with results that are far superior in precision and repeatability. Additionally, it can handle tools from multiple brands, so even if you only use one brand such as Dremel or Shop Fox, the Woodworker II will still get your job done right every time. This makes it an invaluable asset for woodworkers looking for the best results possible from their tools.

Different Techniques for Learning to Sharpen with the Woodworker II

Learning how to sharpen woodworking tools with the Woodworker II is an incredibly useful skill for any woodworker. Here are some of the techniques that can be used to hone your sharpening skills and make sure each tool you’re sharpening comes out flawlessly:

• Start with a coarse stone: Using a coarse stone will help to remove more material at a faster rate when you need to do major repairs on your blades and other tools quickly.

• Move onto the medium stone: Once you have removed most of the nicks and damage, switch over to the medium stone. This will start to smooth the edges and refine them further.

• Finish up with fine grits: The last stage of sharpening should always involve a finer grit, as this will help create an even more perfect polish on your blade or chisel edge.

• Use honing paste: After using honing stones, make sure your blade is completely free from burrs by applying honing paste onto an old rag or cloth and rubbing it gently across the blade in circular motions. This will remove any tiny imperfections and disperse dirt evenly, creating an even edge afterwards.

• Experiment with angles: Angles play a crucial role in achieving sharpness, so take some time to experiment with different angles until you find one that gives you optimum performance results without too much effort invested.

By following these steps on each tool you work on, you’ll soon become expert at using the Woodworker II sharpener!

Examples of Tools successfully Sharpened with Woodworker II

Woodworker II is an effective and reliable sharpening device used to hone and sharpen various blades. It is a versatile tool that is suitable for both professional woodworkers and hobbyists. Through the use of its efficient honing disc system, even complex edges can be addressed with precision and accuracy.

The Woodworker II sharpening device can successfully sharpen almost any cutting tool, including chisels, router bits, planer blades, saw blades (rip, crosscut, miter, band saw), carving tools (froe, adze hail bitt & drawknifes) lathe tools (bowl & spindle gauge), knives (scissors & kitchen knives), screwdrivers & augers. It is also capable of sharpening and polishing round abrasive burrs/files for shaping and detail work in hard or soft metals as well as texturing leather. Furthermore, it has two interchangeable slots so you can easily switch out other honing discs to suit your specific projects or preferences.

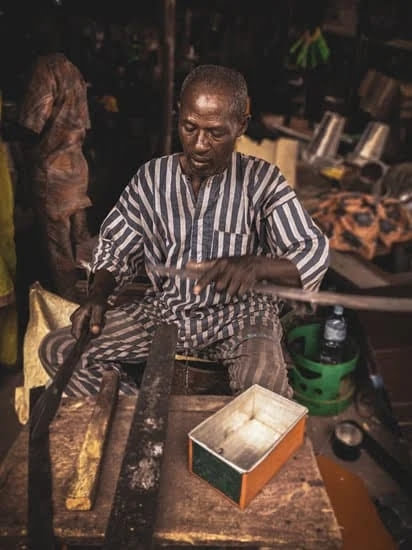

Showcase Work Examples of Woodworker II Sharpening

Woodworker II Sharpening is an important skill for any woodworking professional. To demonstrate the skill of Woodworker II Sharpening, there are a few examples that can be shown to potential employers or clients. For example, one might show the before and after of sharpened tools such as chisels, gouges and carving tools by providing photos of each tool before it was sharpened and then after the sharpening process. Additionally, an example of a chip-out removal on outside curves can be used as another showcase work item. This demonstration should explain how a dull cutter was reshaped with relief controlled facets while keeping the radius of curvature as close to original as possible. Finally, tear out prevention on figured woods such as walnut or mahogany also shows one’s proficiency in Woodworker II Sharpening. With a picture or sample piece of wood, one can easily showcase their ability to sharpen even small intricate details such as paring knife bevel angles that prevent tear out from happening.

Videos for Visual Reference on Woodworker II Sharpening

Woodworking requires careful maintenance of tools and an understanding of proper sharpening techniques. To help, there are a variety of videos available online that provide visual reference for woodworker II sharpeners. In these video reviews, professionals show viewers the best practices for achieving a “razor-sharp edge” when working with wood in order to produce optimal results. By watching these videos, amateur and professional woodworkers alike can learn about the types of chisels, knives and other tools needed for their projects, as well as the basics of sharpening those tools using tried-and-true methods. The videos also demonstrate how to approach more complex tasks like honing an edge on a plane iron or creating a perfect joint. In addition to sharpening tutorials, there are also reviews and demonstrations discussing other topics such as selecting the right type of blade material, choosing between various grits on sand paper and properly maintaining your tools. With enough practice and guidance from expert woodworkers, anyone can master the art of using woodworker II sharpener to achieve optimal results every time they work with wood.

Testimonials and Stories from Other Woodworkers

Woodworker II Sharpening is a respected and widely-used sharpening system amongst professionals in the woodworking industry. It is highly praised for its ease of use, cutting edge technology, precision accuracy, and durability. Many professional woodworkers who have used Woodworker II Sharpening rave about it’s ability to give their tools a sharper edge than ever before. One of them said “it changed my whole relationship with hand tools” They also love that it is able to sharpen all kinds of tools from chisels, planes and router bits to saw blades.

The user-friendly design of Woodworker II Sharpening allows even beginners to the world of woodworking to quickly get up and running with it. People love that it allows for smooth adjustment and fine tuning which ensures perfect results every time. On top of that it provides noise reduction features since sharpening processes usually create quite loud noises due to the use of grinders and other type of machines.

Many satisfied customers say they enjoy being able to get results they couldn’t have achieved on their own or by using other less efficient sharpeners on the market today. The accuracy this machine produces has enabled woodworkers to increase their productivity while ensuring consistent quality tool edges which result in an improved finish on each project they do. All these features make WoodworkerII Sharpening a great choice for anyone looking for professional-level performance without a steep learning curve or extensive maintenance requirements.

Maintenance and Care Tips for Woodworker II

Woodworker II is a top of the line tool for all types of woodworking projects. It is important to maintain and care for your Woodworker II in order to ensure it runs smoothly and efficiently. Here are some tips for maintaining and caring for your Woodworker II:

1. Keep the tool clean: Wood particles can quickly accumulate on a Woodworker II, making it difficult to operate properly. Regularly ensure that all surfaces of the tool are clear of dirt, dust, and sawdust build-up by wiping away with a damp cloth or brush.

2. Sharpen blades regularly: Sharpening blades regularly will help keep them from becoming dull over time. Pay special attention to the angles of the sharpened blades as these will affect their cutting performance. For more information on sharpening techniques consult your user manual or seek professional advice if necessary.

3. Check connections: Look at all connections on your Woodworker II such as power cords, plugs, bearings, etc., and make sure they are tightened securely to avoid any damage while using the tool.

4. Lubricate frequently: Routine lubrication ensures that moving parts work smoothly without rubbing against each other which could cause damage over time. Refer to your user manual for proper lubricant recommendations and how often you should apply it depending on outside temperature conditions and how often you use the tool.

5. Regularly inspect for damage/wear and tear: Take some time to inspect each component for signs of wear or damage every few weeks or after long periods of use. This helps identify any problems early so you can replace/repair any necessary parts before they become bigger issues down the road.

FAQs and Answers on The Woodworker II Sharpening System

Q: How does the Woodworker II sharpening system work?

A: The Woodworker II is a full-featured sharpening system that uses ultra-precise profiling and grinding technology to ensure perfect angles for honing the blades of almost any woodworking tool. It consists of two main components: an adjustable grinding jig with vertical clamping and a precision V-shaped grindstone support base. This allows you to create custom profiles with repeatable accuracy on the edge of your tools, eliminating premature wear and tear. The sharpening system includes a guide rail to accurately align the blade against the Stone for maximum control, as well as an honing stone which is optimized for fast results. The system also has several automated features such as automatic tool feed, preset speed controls, and fine adjustment knobs to make sure your blades are always in tip-top shape. With these features, you can get consistent results every time you sharpen your woodworking tools with the Woodworker II.

Resource List with Related Books and Articles

Sharpening is an essential skill and art form for any woodworker. Mastering the art of sharpening can help you create your projects with greater precision and control as well as add a unique aesthetic element to your work. If you’re just getting started as a woodworker, there’s a lot to learn about sharpening tools. To make it easier, we’ve compiled this comprehensive sharpeners resource list so you have all the information you need in one convenient place.

This resource list includes everything from books and articles about the basics of sharpening to tutorials and videos that will guide you through each step. It also has links to some excellent online stores where you can purchase top-quality sharpeners materials and supplies. Finally, it also contains recommendations for professional services should you decide to get assistance from an expert to sharpen your tools.

Books:

• The Complete Guide to Sharpening by Leonard Lee – all about how to use basic hand and machine sharpeners correctly.

• The Perfect Edge: The Ultimate Guide to Sharpening for Woodworkers by Ron Hock – this book covers both the basics of sharpening as well as more complex techniques such as using powered grinders and honing sticks.

• Tool Sharpening by John Egeler – this book provides clear instruction on leveraging bench stones, chisels, planes, knives and other miscellaneous tools during sharpening process.

Articles:

• “Sharpening Basics: Getting a Razor Edge Every Time You Use Your Tools” by Paul Mayer on Popular Woodworking Magazine – offers insight into choosing the right material when buying a new tool, caring for tools while they’re in use, and how to properly set bevel angles when sharpening various shapes of blades (e.g., square or spear point).

• “The Art of Honing To Produce Super-sharp Edges On Your Hand Tools” by Antoine Bergeron on Canadian Woodworking Magazine – explains how honing helps produce finely polished edges with very little effort; particularly useful for restoring older dulled hand tools due its quick touch-up capabilities.

• “How To Sharpen Chisels With Flattened Waterstones” on Tools Today – offers practical advice around developing proper technique with flattened stones which require fewer triangles than their round counterparts; includes illustrations that demonstrate easy setup of hand planers without having any prior experience in tool grinding equipment whatsoever.

Professional Services:

• Stephen Snell workshop run by Stephen Snell in Cornwall, UK – specializes in leather strops which he personally develops using traditional methods; understand them well enough even if no prior experience with razor honing practicing styles had been obtained at some stage earlier before acquiring his knowledge resources adequately later away from being educated himself too exhaustively afterwards surely!

• Blotier & Sonan Fine Bladesmiths based out of Clemson, South Carolina – deals in making superior quality Japanese style blades which are created using high carbon steel alloy materials; have their own knife sharpening service open only during weekends just like that!

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.