Woodworking Plans Coffee Table

A coffee table is a piece of furniture that is typically found in the living room or sitting room of a house. It is usually a low table that is used to place drinks on, or to rest one’s feet on. Coffee tables are often found in pairs, and are typically made from wood or glass.

There are many different types of coffee tables, and it can be difficult to choose the right one for your home. If you are looking for a coffee table that is stylish and functional, you may want to consider a woodworking plans coffee table.

A woodworking plans coffee table is a table that is designed to be made from wood. It usually has a rectangular or square shape, and it is often used to place drinks on or to rest one’s feet on. A woodworking plans coffee table is a great option for a stylish and functional table, and it is a great choice for homes that have a rustic or country theme.

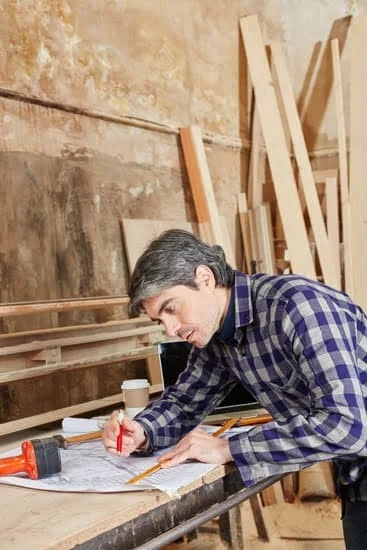

If you are interested in a woodworking plans coffee table, there are many different options available to you. You can find plans for a coffee table that is made from wood online, or you can find plans in magazines or books.

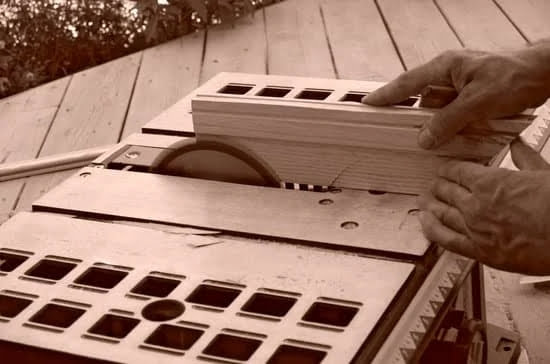

Once you have chosen a plan for a woodworking plans coffee table, you will need to gather the materials and tools that you will need to build it. The materials that you will need will vary depending on the design of the table, but you will typically need wood, screws, nails, and a drill. The tools that you will need will vary depending on the design of the table, but you will typically need a saw, a screwdriver, and a drill.

Once you have gathered the materials and tools that you will need, you can begin construction on your coffee table. The construction process will vary depending on the design of the table, but you will typically need to measure and cut the wood, and then attach it together with screws or nails. Once the table is assembled, you will need to sand and finish it.

If you are interested in a woodworking plans coffee table, there are many different options available to you. A woodworking plans coffee table is a great option for a stylish and functional table, and it is a great choice for homes that have a rustic or country theme.

Dog House Woodworking Plans

1. Introduction

A dog house is a structure designed to provide a dog with shelter from the elements. While traditionally made of wood, modern dog houses often feature a variety of materials, including plastic and metal.

2. Types of Dog Houses

There are a variety of different types of dog houses available on the market, including:

· Outdoor dog houses: These are designed to be placed outdoors and provide dogs with shelter from the elements.

· Indoor dog houses: These are designed to be placed indoors and provide dogs with a designated space to sleep in.

· Travel dog houses: These are designed to be transported with the dog and provide them with a space to sleep while on the go.

3. Size of a Dog House

When choosing a dog house, it is important to consider the size of the dog that will be using it. The dog house should be large enough for the dog to comfortably stand up and turn around in, but not too large that it becomes difficult to keep warm.

4. Building a Dog House

If you are interested in building your own dog house, there are a variety of different plans available online. When building a dog house, it is important to use weather-resistant materials that will protect the dog from the elements.

5. Buying a Dog House

If you are not interested in building your own dog house, there are a variety of different dog houses available for purchase online and in stores. When buying a dog house, it is important to consider the size of the dog that will be using it, as well as the climate in which you live.

Outdoor Sectional Woodworking Plans

The first step to starting any woodworking project is to gather the necessary tools and materials. This includes a set of plans, a saw, a drill, clamps, wood glue and a hammer. With these tools, it is possible to build a beautiful and sturdy outdoor sectional.

The first step is to cut the lumber to the correct size. This can be done with a saw. The lumber should be cut into four equal pieces, two for the back and two for the seat. The back pieces should be 32 inches long and the seat pieces should be 18 inches long.

The next step is to drill the holes for the screws. This can be done with a drill. The holes should be drilled in the back pieces, two in the top and two in the bottom. The holes should be drilled in the seat pieces, two in the top and two in the bottom. The holes should be 1 inch from the edge of the lumber.

The next step is to glue the pieces together. This can be done with wood glue. The back pieces should be glued to the seat pieces. The top of the back pieces should be glued to the top of the seat pieces and the bottom of the back pieces should be glued to the bottom of the seat pieces.

The next step is to screw the pieces together. This can be done with a screwdriver. The screws should be inserted in the holes that were drilled in the previous step. The screws should be inserted in the top of the back pieces and the bottom of the back pieces.

The final step is to hammer in the nails. This can be done with a hammer. The nails should be inserted in the holes that were drilled in the previous step. The nails should be inserted in the top of the back pieces and the bottom of the back pieces.

The completed outdoor sectional can be stained or painted to match any décor. It is sure to be a beautiful and functional addition to any outdoor space.

Free Pool Table Woodworking Plans

Pool tables are a great addition to any game room, and they can be a lot of fun to play on. If you’re interested in building your own pool table, there are a few different free pool table woodworking plans out there that you can use as a guide.

The first step in building your own pool table is to measure the space where you want to put it. You’ll need to make sure that the table will fit in the space, and that you have enough room to move around it.

Once you’ve measured the space, you can start planning the design of your table. There are a few different designs that you can choose from, but most pool tables are either six or eight feet long. You’ll also need to decide on the height of the table, and whether you want it to have a straight or curved top.

Once you’ve decided on the design of your table, you can start planning the construction. The most important part of the construction is the frame, so make sure that you build it sturdy. You’ll also need to make sure that the table is level, so use a spirit level to check the surface before you start attaching the boards.

The final step in building your own pool table is to attach the cloth. You can buy cloth specifically for pool tables, or you can use an old tablecloth that you have lying around. Make sure that the cloth is stretched tight, and that there are no wrinkles in it.

If you follow these simple steps, you can have your very own pool table in no time. Just be sure to measure the space carefully, and to build the frame sturdy so that the table will last for years to come.

Cabinet Humidor Woodworking Plans

A humidor is a box, usually made of wood, that is used to store cigars at a constant humidity level. The humidity level is important because it helps to keep the cigars in good condition, and prevents them from drying out or becoming moldy.

If you are interested in making your own humidor, there are a few things you will need to know. The first thing is the size of humidor that you want to make. This will determine the size of the box that you need to build, as well as the size of the humidifier and the hygrometer.

The next thing you will need to know is the type of wood that you want to use. The most popular type of wood for humidors is cedar, because it is a natural insect repellent and it helps to keep the cigars in good condition. Other types of wood that can be used for humidors include mahogany, walnut, and oak.

Once you have determined the size and type of wood that you want to use, you can begin to build the humidor. The first step is to cut the pieces of wood that you will need for the box. The sides, top, and bottom of the humidor should all be made out of cedar, while the front and back can be made out of a different type of wood.

Once the pieces are cut, you can start to assemble the humidor. The easiest way to do this is to use a T-bar construction. First, you will need to drill holes in the sides, top, and bottom of the box. The holes should be the same size as the T-bars. Then, you can insert the T-bars into the holes and screw them in place.

Next, you will need to attach the front and back of the humidor to the sides. You can do this by drilling screws through the front and back and into the sides of the box.

The last step is to install the humidifier and the hygrometer. The humidifier should be attached to the bottom of the humidor, and the hygrometer should be attached to the inside of the lid.

Once the humidor is assembled, you will need to fill it with a humidifying agent. This can be done by adding distilled water to the humidifier, or by using a humidifying gel. You will also need to set the humidity level. This can be done by using a hygrometer, or by trial and error.

The final step is to wait a few days for the humidor to stabilize, and then start storing your cigars in it.

Hi everyone! I’m a woodworker and blogger, and this is my woodworking blog. In my blog, I share tips and tricks for woodworkers of all skill levels, as well as project ideas that you can try yourself.